It’s a scenario every dental lab technician dreads. You open the furnace after a multi-hour sintering cycle, only to find a costly zirconia bridge with a tell-tale micro-fracture. Or perhaps you get the dreaded call from the dentist: "The shade on this crown is off, we can't seat it."

Your heart sinks. Hours of skilled work and hundreds of dollars in materials are instantly wasted. You followed the material instructions perfectly. You cleaned the furnace just last week. So, what went wrong?

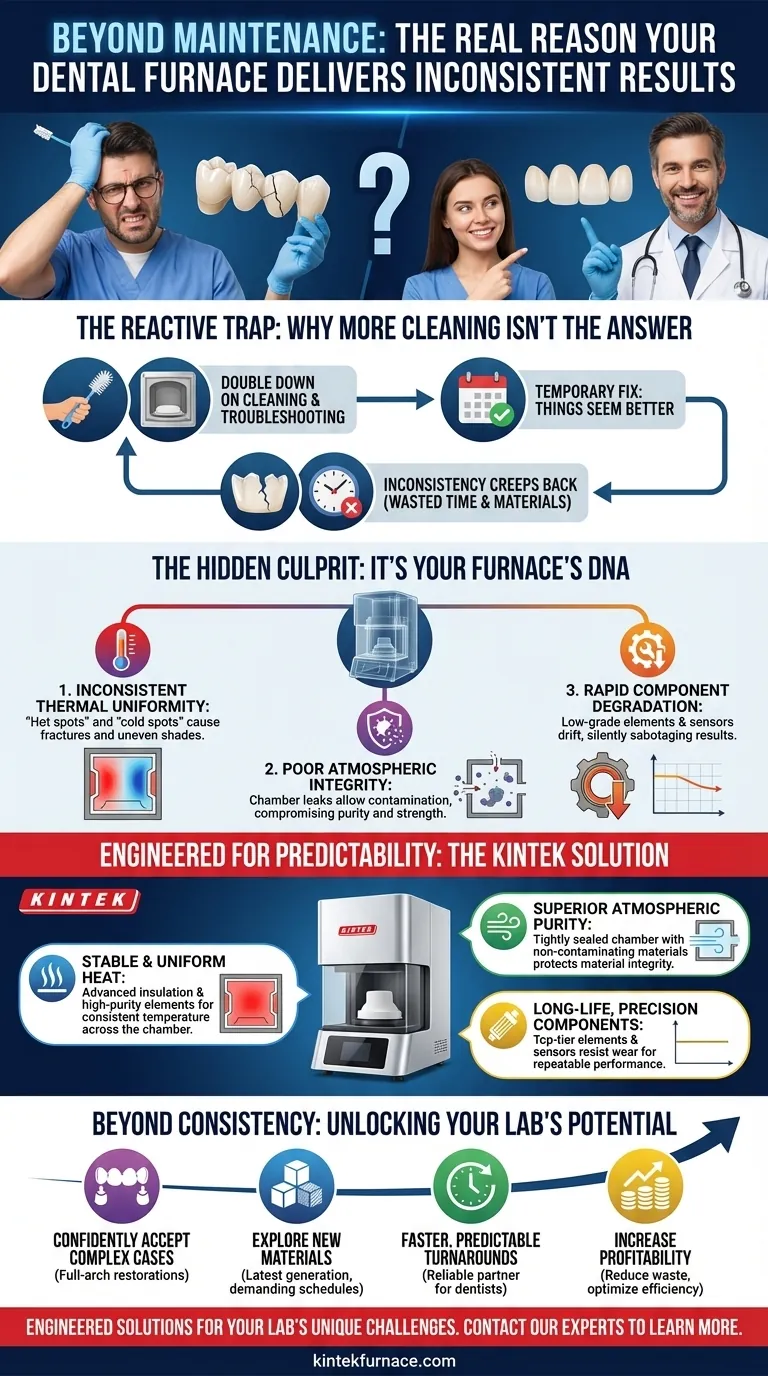

The Reactive Trap: Why More Cleaning Isn't the Answer

When faced with inconsistent outcomes, most labs fall into a frustrating, reactive cycle. The immediate response is to troubleshoot the process:

- Double down on cleaning: The team is instructed to clean the furnace chamber meticulously before every run.

- Question the staff: Was the correct program used? Was the material handled properly?

- Schedule another service call: A technician comes in, runs diagnostics, calibrates the thermocouple, and gives a thumbs-up.

For a little while, things might seem better. But soon enough, the inconsistency creeps back in. This isn't just a technical frustration; it has severe business consequences. Each failed prosthetic means wasted material costs, lost technician hours, delayed deliveries to dentists, and a slow erosion of your lab's reputation for quality and reliability.

The hard truth is that while diligent maintenance is essential, it often only treats the symptom, not the disease. You're trapped in a cycle of fixing a problem that is destined to reappear, because the real issue lies deeper.

The Hidden Culprit: It's Not Your Process, It's Your Furnace's DNA

The most overlooked factor in achieving consistent, high-quality dental prosthetics is the fundamental engineering of the furnace itself. Many standard furnaces, despite looking professional, have inherent design limitations that no amount of cleaning or calibration can permanently overcome.

The problem originates from three core areas:

1. Inconsistent Thermal Uniformity

Many furnaces suffer from "hot spots" and "cold spots" within the chamber. This means a full-arch restoration might be exposed to slightly different temperatures across its length during the critical sintering phase. This thermal variance creates internal stresses, leading to fractures, and causes uneven translucency and inaccurate shades. You can't clean away a hot spot; it's built into the furnace's design.

2. Poor Atmospheric Integrity

The sintering process for materials like zirconia is highly sensitive to atmospheric contamination. Microscopic airborne particles or impurities from lower-grade insulation or heating elements can settle on the restoration, compromising the material's final shade and strength. If a furnace isn't built with high-purity materials and a tightly sealed chamber, you are fighting a losing battle against contamination in every cycle.

3. Rapid Component Degradation

The performance of a furnace is only as good as its core components. In many units, the heating elements and temperature sensors (thermocouples) degrade relatively quickly under intense, repeated use. As they wear out, their performance drifts. A technician can recalibrate a drifting thermocouple, but if the component itself is low-grade, it will simply start drifting again, slowly and silently sabotaging your results.

In short, you've been trying to solve a hardware problem with a software (process) fix.

Engineered for Predictability: The Right Tool for the Job

To escape the reactive maintenance trap, you need to shift your focus from constant intervention to investing in a tool that is fundamentally designed for consistency. A furnace shouldn't be a variable you have to constantly manage; it should be a reliable platform that empowers your craftsmanship.

This is precisely the principle behind KINTEK's furnace solutions. We engineer our systems based on a deep understanding of the materials science involved in dental prosthetics.

- To solve thermal non-uniformity: Our furnaces are designed with advanced insulation and strategically placed, high-purity heating elements that deliver exceptionally stable and uniform temperature distribution across the entire firing chamber. This ensures every unit in a batch, from a single crown to a full bridge, receives the exact same thermal treatment.

- To solve contamination: We build our furnace chambers with the highest quality, non-contaminating materials and precision engineering to ensure superior atmospheric integrity, protecting the purity and intended shade of your advanced materials.

- To solve component degradation: We utilize top-tier, long-life heating elements and thermocouples that resist wear and maintain their calibration for thousands of hours, providing predictable and repeatable performance you can trust, day in and day out.

Furthermore, we recognize that no two dental labs are identical. Our deep customization capabilities allow us to tailor a furnace solution to your specific materials, workflow, and volume, turning it into a seamless and reliable part of your production line.

Beyond Consistency: Unlocking Your Lab's True Potential

When your furnace transforms from a source of uncertainty into a pillar of reliability, something powerful happens. The focus of your lab shifts.

Instead of spending time and resources on remakes and troubleshooting, your team can:

- Confidently accept more complex cases: Take on high-value, full-arch restorations knowing your equipment can deliver flawless results.

- Explore new materials: Adopt the latest generation of dental materials that often have more demanding and precise firing schedules.

- Guarantee faster, predictable turnaround times: Build stronger relationships with your dental clients by becoming their most reliable partner.

- Increase profitability: Dramatically reduce material waste and optimize labor efficiency, directly boosting your bottom line.

Solving your inconsistency problem isn't just about fixing a technical issue; it's about unlocking the next stage of your lab's growth and reputation.

Your lab's challenges with materials, throughput, and consistency are unique. Our team doesn't just sell furnaces; we engineer solutions for the specific demands of advanced dental labs. Let's discuss the challenges you're facing and explore how a furnace built on a foundation of engineering excellence can provide the stability and precision your work deserves. Contact Our Experts.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

Related Articles

- Mastering the Void: How Vacuum Furnaces Forge Strength and Beauty in Dental Restorations

- Why Your Vacuum Furnace Failed After the Lab Move—And How to Prevent It

- Why Your Sintered Parts Fail: It’s Not Just About Heat, But Pressure and Purity

- The Microwave Sintering Trap: Why the 'Best' Furnace Might Be the Wrong Choice for Your Lab

- How Vacuum Hot Press Furnaces Transform Advanced Material Engineering