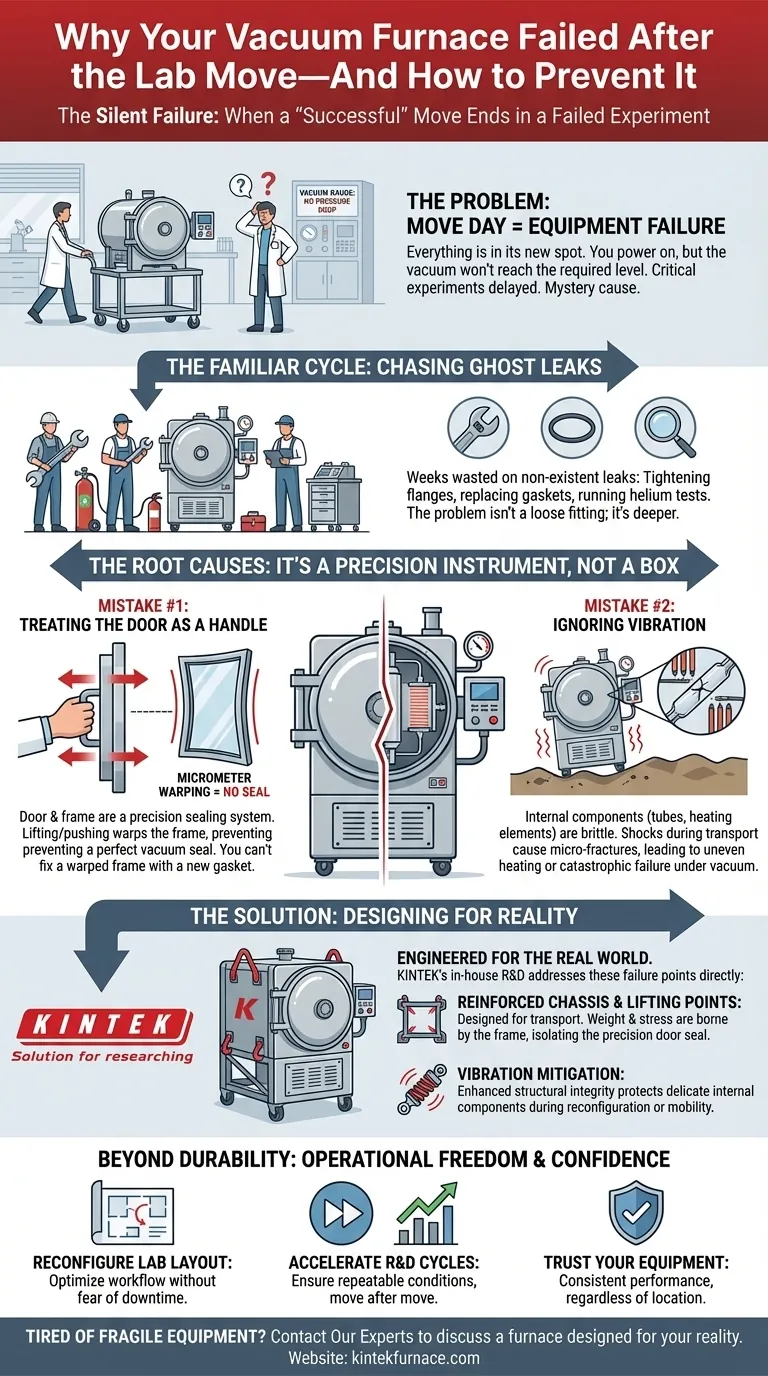

The Silent Failure: When a "Successful" Move Ends in a Failed Experiment

The lab relocation is finally over. Everything is in its new, pristine spot. You power on your vacuum tube furnace, start the pump-down for a critical experiment, and wait. And wait.

But the vacuum gauge barely moves. The pressure won't drop to the required level. You check the connections, inspect the flanges, and run through the checklist, but find nothing. Weeks of work are suddenly on hold, and the cause is a complete mystery. The move seemed successful, but your most critical piece of equipment is now inexplicably non-functional.

The Familiar Cycle of Frustration: Chasing Leaks That Aren't There

This scenario is far too common. A lab invests tens of thousands of dollars in a high-performance furnace, only to see it fail after a seemingly simple relocation across the room or across campus.

The immediate reaction is to troubleshoot for a leak. Teams spend days, even weeks, on a frustrating hunt for the source:

- Checking and re-tightening every flange and fitting.

- Replacing gaskets and O-rings.

- Running helium leak detectors over every inch of the system.

These efforts are almost always a dead end. Meanwhile, the consequences mount. Critical R&D projects are delayed, production schedules slip, and the cost of wasted technician time and halted operations skyrockets. The root of the problem isn't a loose fitting; it's a fundamental misunderstanding of the equipment itself.

The Root of the Problem: It’s Not a Box, It’s a Precision Instrument

The critical error is treating a vacuum furnace like a heavy-duty appliance. In reality, it is a finely tuned instrument where mechanical integrity is inseparable from scientific performance. The damage doesn't happen when you try to turn it on; it happens during the move itself, caused by two seemingly minor mistakes.

Mistake #1: Treating the Door as a Handle

The furnace door looks like a sturdy place to get a grip. This is a catastrophic error. The door and its frame are a precision-engineered sealing system. Lifting or even pushing on the door can warp the frame by mere micrometers. While invisible to the naked eye, this minuscule distortion is more than enough to prevent the gasket from creating a perfect vacuum seal ever again. You are essentially trying to fix a leak when the entire door frame has been bent out of shape.

Mistake #2: Ignoring Vibration

A furnace's internal components—the quartz or ceramic tube and the brittle heating elements—are designed to withstand extreme temperatures, not physical shock. When the unit is rolled over an uneven floor, bumped, or jolted, vibrations travel through the chassis. These shocks can create micro-fractures in the process tube or damage the heating elements. The result is uneven heating, poor temperature uniformity, or even a catastrophic failure of the tube under vacuum and heat.

The "common solutions" of checking external seals fail because the damage is structural and internal. You're searching for a faulty component when the very foundation of the system has been compromised.

Designing for Reality: A Furnace Built to Withstand the Real World

To truly solve this problem, you need more than just a careful moving plan. You need a furnace that was engineered from the start with an understanding of real-world laboratory conditions. A solution isn't just about performance in a static environment; it's about reliability throughout the equipment's entire lifecycle, including installation and relocation.

This is where design philosophy makes all the difference. At KINTEK, our in-house manufacturing and R&D process allows us to address these failure points directly in the engineering phase.

- Solving the Frame Warp Issue: Our vacuum furnaces are constructed with a reinforced chassis and clearly designated, structurally sound lifting points. The design ensures that the weight and stress of a move are borne by the frame, completely isolating the precision-machined door and seal from any load-bearing forces.

- Mitigating Vibration Damage: We understand that your lab's needs change. Our deep customization capability means we can build furnaces with enhanced structural integrity specifically for environments that require frequent reconfiguration or mobility, ensuring the delicate internal components are protected.

Our furnaces are not just designed to perform a task; they are built to last, providing consistent, reliable results because they are engineered to handle the physical realities of their environment.

Beyond Durability: The Freedom of a Truly Reliable Tool

When you no longer have to worry about an accidental bump destroying your most valuable asset, new possibilities open up. You gain the operational freedom and confidence that are essential for innovation.

With a furnace designed for real-world durability, you can:

- Reconfigure your lab layout to optimize workflow as your projects evolve, without fear of costly downtime.

- Accelerate R&D cycles by minimizing equipment-related disruptions and ensuring repeatable experimental conditions, move after move.

- Trust your equipment implicitly, knowing that its performance today will be the same as its performance tomorrow, regardless of its location in your facility.

A furnace that can't be moved without risk is a constraint on your entire operation. A robust, intelligently designed furnace becomes a true enabler of your scientific and production goals.

Our team understands that true value lies not just in high-temperature performance, but in robust engineering that supports your work day-in and day-out. If you're tired of fragile equipment dictating your lab's potential, let's discuss how a furnace designed for your reality can accelerate your goals. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

Related Articles

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Unseen Enemy: Why Vacuum Furnaces Are a Bet on Perfection