The Hidden Variable in Every High-Temperature Experiment

Imagine months of work culminating in a final, critical step: the high-temperature annealing of a novel semiconductor crystal. The formula is perfect. The atmospheric controls are precise. The temperature profile is programmed to the fraction of a degree.

Yet, the result fails. The material’s properties are inconsistent.

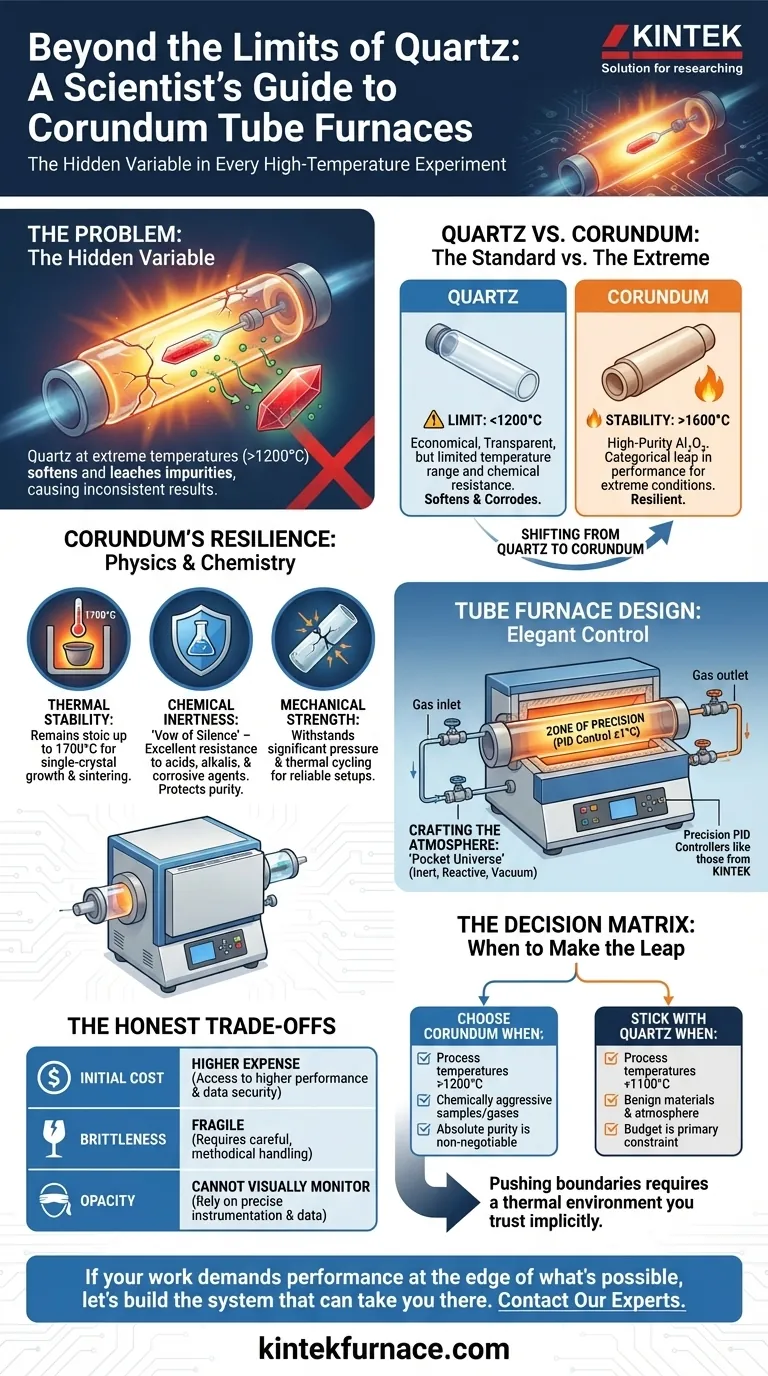

The culprit isn't the process; it's the environment. At extreme temperatures, the very tube containing the experiment can become an active, unwanted variable, leaching subtle impurities into the sample. This is the silent failure point that haunts materials science—a problem solved not by better software, but by a better material.

The Bright Line Between the Standard and the Extreme

In thermal processing, the most fundamental choice is often the vessel itself. For years, quartz has been the reliable workhorse. It’s economical, transparent, and serves countless applications wonderfully.

But quartz has a hard limit. As temperatures climb past 1200°C, it begins to soften. When exposed to certain alkalis or acids, it can corrode. Its limits are not suggestions; they are laws of physics.

Crossing this line requires a different material philosophy. It requires corundum. Shifting from quartz to corundum isn't a simple upgrade; it's a conscious decision to operate in a domain where standard materials fail.

The Physics and Chemistry of Absolute Resilience

Corundum, a high-purity form of alumina (Al₂O₃), isn’t merely stronger than quartz. Its properties represent a categorical leap in performance, engineered for conditions that would destroy lesser materials.

Resisting the Inferno: Stability Beyond 1600°C

Temperatures of 1600°C or 1700°C are not just hot; they are transformative. At this level, atoms rearrange, new crystalline structures are born, and advanced ceramics are sintered into their final, durable forms.

Corundum remains stoic in this environment. Its thermal stability is the bedrock that makes processes like single-crystal growth or the pyrolysis of advanced composites possible and repeatable.

The Vow of Purity: Unrivaled Chemical Inertness

A perfect experiment requires a silent, impartial observer. The furnace tube's primary job is to contain the reaction, not to participate in it. Corundum's exceptional resistance to acids, alkalis, and other corrosive agents is its vow of silence.

This inertness provides a profound psychological relief for any researcher: the certainty that the container is not a confounding variable. The purity of the sample is protected, ensuring the integrity of the final data.

Strength Under Pressure and Through Cycles

Beyond heat and chemistry, mechanical stress is a constant factor. Corundum’s high mechanical strength allows it to withstand significant pressure differentials—essential for high-vacuum applications—and the repeated stress of thermal cycling. This translates directly to a longer service life and, more importantly, a more reliable experimental setup.

The Elegant Control of the Tube Furnace Design

A superior material is only half the solution. The corundum tube is housed within a furnace architecture designed for absolute control.

- A Zone of Precision: The tube furnace design naturally creates a highly uniform hot zone. Paired with modern PID controllers, systems like those from KINTEK can maintain temperature with astonishing precision, often within ±1°C of the setpoint. This ensures that every run is identical to the last.

- Crafting the Atmosphere: The sealed tube is a "pocket universe" for your sample. It allows you to completely control the internal environment, whether it's an inert argon atmosphere to prevent oxidation, a reactive gas for synthesis, or a deep vacuum to remove impurities.

The Honest Trade-Offs

There is no perfect material, only the right material for the job. Choosing corundum means accepting a clear set of trade-offs. It's a high-performance tool, and it demands to be treated as such.

| Consideration | The Reality | The Strategic Perspective |

|---|---|---|

| Initial Cost | Corundum tubes are significantly more expensive than their quartz counterparts. | You are not just buying a tube; you are buying access to a higher-performance regime and insuring against data loss. |

| Brittleness | Like most high-performance ceramics, corundum is brittle and can shatter from impact or severe thermal shock. | It requires careful, methodical handling—a practice already familiar to any meticulous researcher. |

| Opacity | You cannot visually monitor the sample during the process. | This forces a reliance on precise instrumentation and process data, reinforcing a more rigorous scientific method. |

The Decision Matrix: When to Make the Leap

The choice between quartz and corundum is a strategic one, based entirely on the ambitions of your work. The framework is simple:

-

Choose Corundum when:

- Your process temperatures consistently exceed 1200°C.

- Your samples or atmospheric gases are chemically aggressive.

- The absolute purity of your final product is non-negotiable.

-

Stick with Quartz when:

- Your process remains safely below 1100°C.

- Your materials and atmosphere are relatively benign.

- Budget is the primary constraint and the process requirements are modest.

Ultimately, selecting the right furnace is about aligning your equipment's capabilities with your research goals. Pushing the boundaries of material science requires a thermal processing environment that you can trust implicitly. With deep expertise in customizing high-temperature systems—from corundum tube furnaces to complex CVD platforms—the right partner can bridge the gap between ambition and execution.

If your work demands performance at the edge of what's possible, let's build the system that can take you there. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- Why Your High-Temperature Furnace Fails: The Hidden Culprit Beyond the Cracked Tube

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces