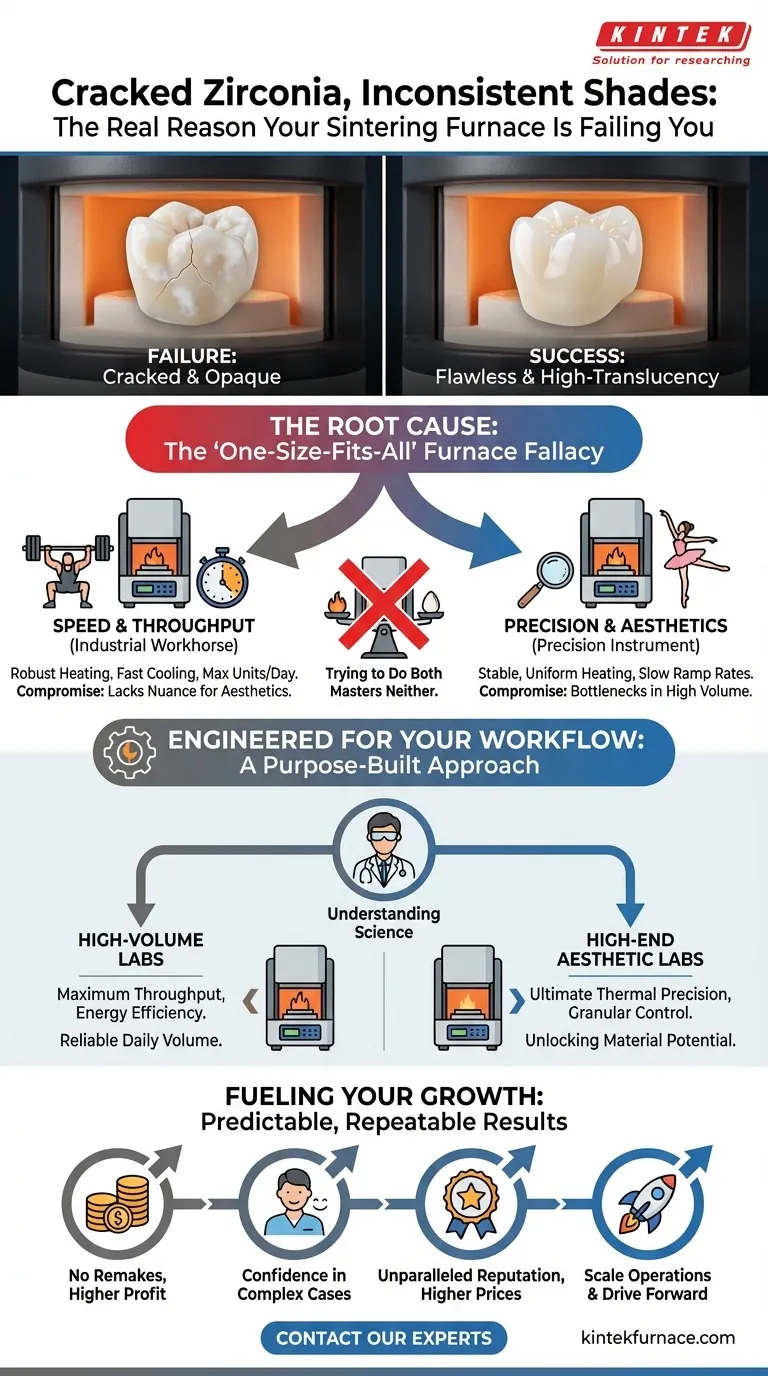

It’s one of the most frustrating moments in any dental lab. A zirconia crown, meticulously designed and milled to perfection, emerges from the sintering furnace. But instead of a flawless restoration, you find a hairline fracture. Or perhaps the shade is milky and opaque, completely missing the high-translucency target you promised the clinician. You followed the material manufacturer’s instructions to the letter, yet the result is another costly, time-consuming remake.

If this scenario feels familiar, you are not alone.

The Vicious Cycle of 'Good Enough' Sintering

Many labs find themselves trapped in a cycle of unpredictable sintering outcomes. When failures occur, the troubleshooting process begins. Was it a bad batch of zirconia? Was the program entered incorrectly? Technicians spend hours adjusting ramp rates and hold times, hoping to find a magic formula.

Often, the next step is to look for a new furnace, armed with a checklist of features: higher temperature, bigger chamber, more pre-set programs, faster cycles. The logic seems sound: a furnace with more capabilities should solve the problem.

But this approach rarely delivers a permanent fix. Instead, it leads to a series of compromises:

- Wasted Energy: You run small, urgent cases in a large-capacity furnace, heating an enormous empty chamber and driving up utility costs.

- Production Bottlenecks: You try to cram a large batch into a smaller furnace, leading to uneven heating and inconsistent results across the units.

- Compromised Aesthetics: You use a "speed" cycle to meet a deadline, only to find the final restoration lacks the vital translucency your clients expect.

These daily struggles have significant business consequences. Each remake erodes your profit margin. Inconsistent quality can damage your lab's hard-won reputation. And when your team is constantly fighting equipment, they have less time for the skilled, value-adding work that truly drives growth.

The Root Cause: The 'One-Size-Fits-All' Furnace Fallacy

The problem isn't your team, your materials, or a lack of features. The root cause is a fundamental misunderstanding of what a sintering furnace is. It’s not just a box that gets hot; it is a highly specific thermal processing engine. And the dirty secret of the industry is that a single furnace cannot be perfectly optimized for every possible outcome.

There is an unavoidable engineering trade-off at the core of every furnace's design:

Speed & Throughput vs. Precision & Aesthetics

- A furnace built for high-volume production is an industrial workhorse. It's designed with robust heating elements and insulation engineered to heat up and cool down quickly and reliably, cycle after cycle. Its primary goal is to maximize the number of units processed per day.

- A furnace built for high-end aesthetics is a precision instrument. Its design prioritizes incredibly stable, uniform heating. It requires nuanced control over very slow ramp rates to prevent thermal shock in advanced, high-translucency materials and to fully develop their optical properties.

The "one-size-fits-all" furnace you bought from a feature list tries to do both, but can master neither. Using its "speed" cycle for an aesthetic case is like asking a powerlifter to perform ballet. And asking a precision furnace to handle high-volume production creates an immediate bottleneck. The common solutions fail because they are just software tweaks on hardware that was never designed for your specific primary goal.

Engineered for Your Workflow, Not a Checklist

To permanently escape this cycle of inconsistency, you don't need a furnace with more buttons. You need a furnace whose core engineering—its chamber dynamics, heating element configuration, and control logic—is perfectly aligned with your lab's primary mission.

This is where a purpose-built approach becomes critical. A solution isn't found in a catalog; it's developed through understanding the underlying science. At KINTEK, we don't just sell furnaces; we engineer thermal solutions. Our foundation in R&D and in-house manufacturing allows us to address the root of the problem:

- For the high-volume production lab: We can provide a furnace engineered for maximum throughput and energy efficiency, with a chamber size and heating elements selected to reliably process your specific daily volume without compromise.

- For the high-end aesthetic lab: We can deliver a furnace designed for ultimate thermal precision, giving you the granular control needed to unlock the full potential of the most advanced zirconia and ceramic materials on the market.

Our deep customization capability means we move beyond the spec sheet. We build a furnace that is a direct answer to the engineering trade-offs, ensuring the tool you have is the exact right tool for your most important jobs.

From Fighting Your Furnace to Fueling Your Growth

Imagine a workflow where every sintering cycle produces predictable, repeatable, and flawless results. What new possibilities would that unlock for your lab?

When your furnace becomes a reliable asset instead of a source of frustration, you're not just saving money on remakes. You gain the confidence to take on more complex cases. Technicians are freed from troubleshooting to focus on artistry and innovation. You can build a reputation for unparalleled quality and reliability, allowing you to attract more discerning clients and command higher prices for your work. You can finally scale your operations, knowing your equipment won't just keep up—it will drive you forward.

Solving your sintering problem isn't about buying another piece of equipment; it's about investing in a predictable outcome for your business. Let our team of experts help you diagnose the unique challenges of your workflow and engineer a solution that turns your biggest production headache into your greatest competitive advantage. Contact Our Experts to start the conversation.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- Beyond 1600°C: The Psychology of Precision in Alumina Tube Furnaces

- Why Your Sintered Parts Fail: It’s Not Just About Heat, But Pressure and Purity

- The Physics of a Flawless Smile: Mastering Material Science with Vacuum Furnaces

- The Microwave Sintering Trap: Why the 'Best' Furnace Might Be the Wrong Choice for Your Lab