The Illusion of Emptiness

In any precision craft, the greatest risks are often the ones you cannot see. For a dental technician, one of the most significant variables is the very air inside the furnace.

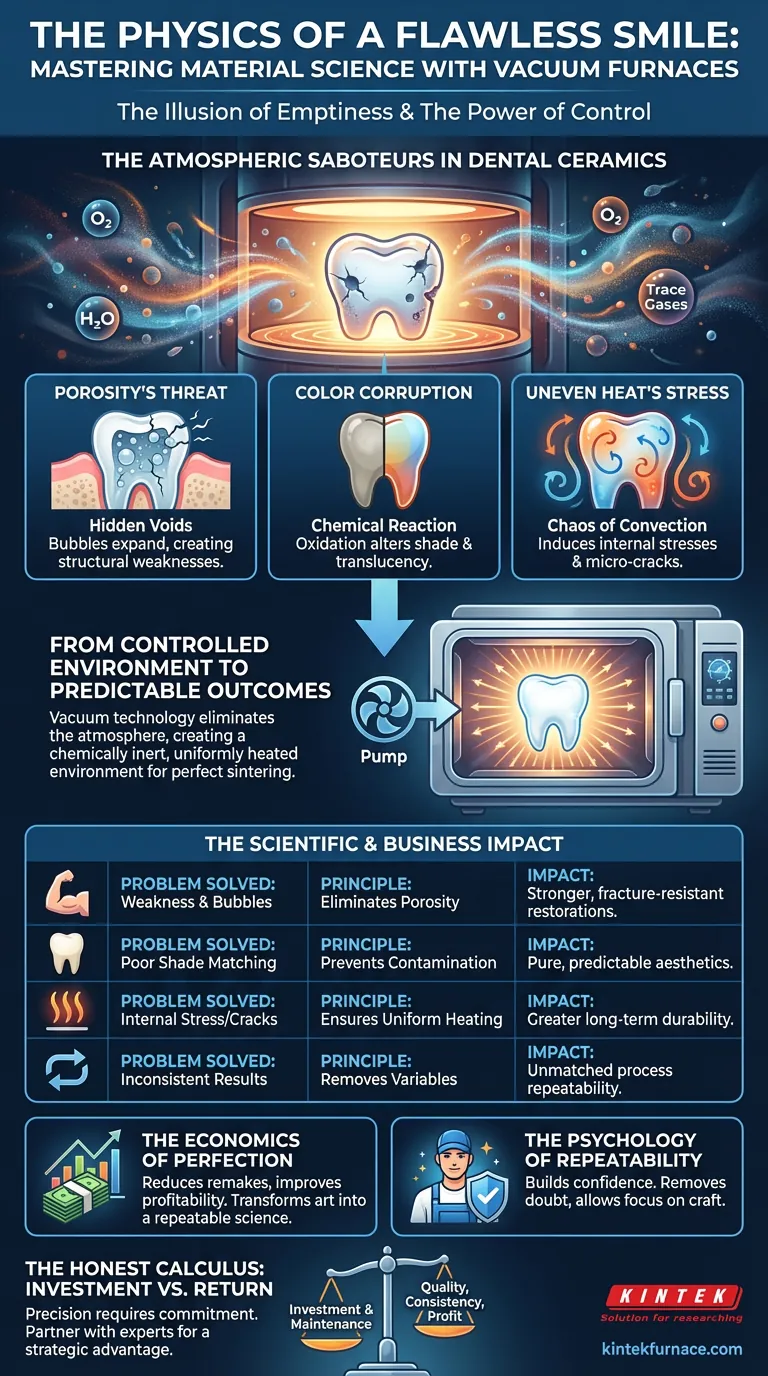

It feels empty, but it's not. The atmosphere is an active, unpredictable participant in the high-temperature firing of dental restorations. It contains oxygen, moisture, and trace gases that can sabotage the final product in subtle yet catastrophic ways.

The challenge isn't just about heat; it's about control. And the ultimate form of control is creating an environment where the material can achieve its perfect, intended state without interference. This is the domain of vacuum technology.

The Atmospheric Saboteurs in Dental Ceramics

To understand why a vacuum is so critical, we must first identify the enemies it removes. The air we breathe is hostile to the delicate chemistry of modern dental materials like porcelain and zirconia.

The Hidden Voids: Porosity's Threat to Strength

Imagine a beautifully sculpted porcelain layer entering the furnace. As the temperature rises, any microscopic air bubbles trapped within the material expand. In a normal atmosphere, these bubbles have nowhere to go. They become permanent voids.

These voids are more than just aesthetic blemishes; they are structural weaknesses. They act as stress concentration points, making the final restoration brittle and prone to fracture.

A vacuum pump removes the air from the firing chamber before this critical temperature is reached. By eliminating the atmosphere, it prevents the formation of these voids, resulting in a restoration that is dense, strong, and structurally sound.

The Chemical Reaction: When Air Corrupts Color

An artist spends hours meticulously matching the shade of a restoration. Yet, after firing, the color is off—dull, opaque, or slightly discolored. The culprit? Atmospheric contamination.

At high temperatures, oxygen and moisture in the air react with the metallic oxides and elements within dental ceramics. This oxidation process can alter the material's intended shade and translucency.

A vacuum creates a chemically inert environment. By removing the reactive gases, it ensures the material's chemistry remains pure. The color you designed is the color you get, with unwavering consistency.

The Chaos of Convection: Uneven Heat's Silent Stress

In an air-filled furnace, heat transfer is a messy combination of radiation and convection. Convection currents create an unpredictable, swirling environment with hot and cold spots across the restoration.

This uneven heating induces internal stresses within the material, which can later manifest as micro-cracks or complete fractures.

In a vacuum, heat transfer is dominated by uniform radiation. Every surface of the restoration receives heat at the same, predictable rate. This gentle, even process is essential for achieving a complete, stress-free sinter.

From a Controlled Environment to Predictable Outcomes

The scientific principles translate directly into powerful operational and clinical advantages. This is where the engineering romance of a perfect environment meets the psychological relief of a predictable business.

| Problem Solved | Scientific Principle | Clinical/Business Impact |

|---|---|---|

| Weakness & Bubbles | Eliminates Porosity | Stronger, fracture-resistant restorations |

| Poor Shade Matching | Prevents Contamination | Pure, predictable aesthetics and translucency |

| Internal Stress/Cracks | Ensures Uniform Heating | Greater long-term durability |

| Inconsistent Results | Removes Atmospheric Variables | Unmatched process repeatability, cycle after cycle |

The Economics of Perfection

A failed restoration isn't just a waste of material. It's a waste of time, a delay for the patient, and a blow to the lab's reputation. The single greatest cause of inconsistency is the daily fluctuation in atmospheric conditions like humidity.

A vacuum furnace eliminates this variable entirely. By creating the exact same pristine environment for every cycle, it transforms firing from a temperamental art into a repeatable science. This drastically reduces remakes, directly improving profitability and throughput.

The Psychology of Repeatability

For a master technician, confidence is paramount. The goal is not to produce one perfect restoration, but to produce them flawlessly every time. A vacuum system provides the foundation for this confidence.

It removes the nagging doubt and anxiety that come from unpredictable variables, allowing the technician to focus solely on their craft, knowing the equipment will deliver identical conditions on demand.

The Honest Calculus: Investment vs. Return

Of course, a precision instrument requires a corresponding commitment. Furnaces equipped with high-quality vacuum systems carry a higher initial investment than simple atmospheric ovens.

Furthermore, they require diligent maintenance. Seals must be clean and pumps must be serviced to ensure a perfect vacuum is achieved every time.

This isn't a drawback; it's a mark of professionalism. The decision becomes a simple calculation: is the cost of the investment and maintenance less than the ongoing cost of remakes, wasted materials, and inconsistent quality? For high-end dental labs, the answer is unequivocally yes.

This is why partnering with an expert manufacturer is critical. A furnace is not a commodity. It is a core piece of your quality control system. KINTEK, with its deep R&D and manufacturing expertise, provides customizable furnace solutions—including Muffle, Tube, and advanced Vacuum systems—engineered to meet the specific demands of dental materials. Our systems are designed for reliability and precision, making the investment a strategic advantage, not just a cost.

A vacuum furnace elevates your work from simple heating to applied material science. It is the definitive tool for any lab that refuses to let the unseen atmosphere compromise its visible results. For those who view their work as a blend of art and engineering, achieving this level of environmental control is fundamental.

If your lab is ready to eliminate variables and engineer predictability into every restoration, Contact Our Experts

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- Beyond the Limits of Quartz: A Scientist's Guide to Corundum Tube Furnaces

- The Hidden Saboteur in Your High-Temperature Furnace: Why Your Melts Are Inconsistent—And How to Fix It

- Beyond Maintenance: The Real Reason Your Dental Furnace Delivers Inconsistent Results

- Cracked Zirconia, Inconsistent Shades: The Real Reason Your Sintering Furnace Is Failing You

- How Vacuum Hot Press Furnaces Transform Advanced Material Engineering