You’ve spent weeks refining your process. The raw materials are of the highest quality, the parameters are meticulously set. You pull the first sample from your vacuum hot press, and it’s perfect—dense, pure, and possessing exactly the properties you engineered. Victory.

But the next batch is a failure. And the one after that. Suddenly, your results are plagued by porosity, oxidation, or poor bonding. You're left staring at a pile of expensive scrap material, wondering, "What went wrong? We changed nothing."

This scenario is the silent frustration in advanced material labs everywhere. It’s a problem that seems to defy logic, turning promising research into a battle against the equipment itself.

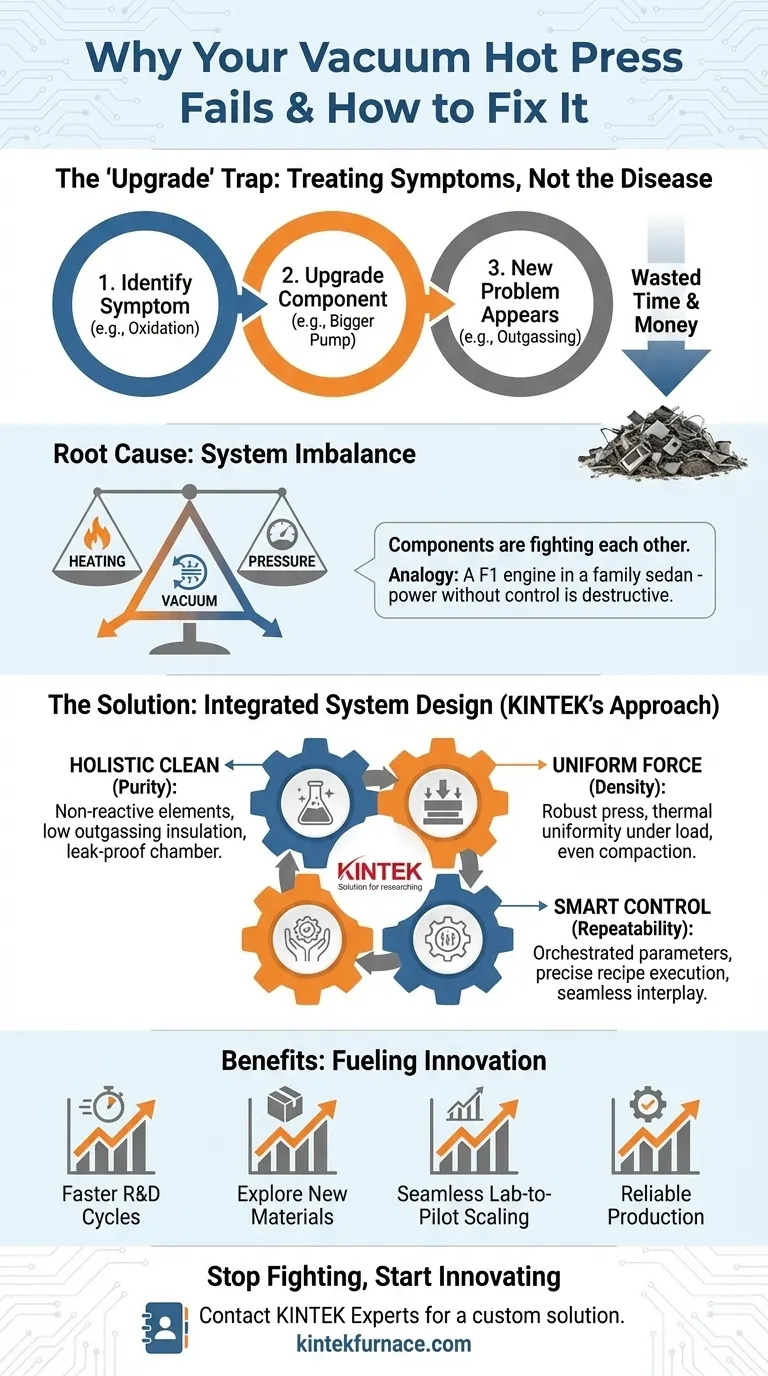

The Vicious Cycle of 'Upgrades' and Setbacks

When faced with inconsistency, the logical first step is to troubleshoot the components. The thinking goes:

- "We're seeing oxidation." The obvious fix? "Let's invest in a more powerful vacuum pump to pull a deeper vacuum."

- "Our material isn't dense enough." The clear solution? "We need a hydraulic press that can apply more force."

- "The process is taking too long." The simple answer? "Let's install higher-temperature heating elements."

So you upgrade a component, run the test again, and for a moment, it seems to work. But soon, a new, unexpected problem appears. The new vacuum pump struggles because the new heating elements are outgassing more than the old ones. The increased pressure causes the sample to crack because the temperature isn't perfectly uniform across the platen. You’ve fixed one symptom only to create another.

This isn't just a technical headache; it's a significant business drain. Each failed run consumes costly advanced materials, pushes project timelines back by weeks or months, and erodes confidence in your ability to scale from R&D to reliable production. You're caught in a costly cycle of whack-a-mole, treating symptoms without ever curing the disease.

The Root Cause: It's Not the Components, It's the Conflict

Here is the fundamental truth that is often missed: A vacuum hot press is not a collection of independent parts. It is a finely balanced, integrated system.

The problem isn't that your vacuum pump is bad or your press is weak. The root cause of your inconsistency is a fundamental imbalance between the three core systems: heating, vacuum, and pressure. They are working against each other instead of in concert.

Think of it like building a race car. You wouldn't put a 1,000-horsepower Formula 1 engine into a standard family sedan. Without upgrading the brakes, suspension, and transmission to match, the power is not just useless—it's destructive.

This is precisely what happens in your furnace:

- A high-power heating system generates immense thermal energy, but it can also cause components to outgas, overwhelming a vacuum system that wasn't designed to handle that specific gas load at that specific temperature.

- A powerful pressing system applies immense force, but it's ineffective if the heating system can't provide absolute temperature uniformity, creating stress points and defects.

- A high-performance vacuum system can create a pure environment, but it's rendered useless if the chamber seals or insulation materials aren't chosen to withstand the target temperature and pressure without leaking or contaminating the process.

The "common sense" upgrades fail because they treat the furnace like a list of parts. They disrupt the delicate equilibrium required for a successful process, guaranteeing that you'll always be chasing the next problem.

The Solution: A Furnace Designed as a System, Not a Sum of Parts

To permanently escape the cycle of inconsistency, you don't need better parts; you need a better-integrated system. You need a furnace where every component is selected and engineered to work in perfect harmony to meet the specific demands of your material and your process.

This is the core philosophy behind KINTEK's furnace solutions. We don't just assemble high-quality components; we engineer cohesive systems. We recognize that the key to repeatability lies in ensuring the heating, vacuum, and pressing capabilities are in perfect balance.

Our deep customization capability is how we deliver on this promise. We build your furnace based on a deep understanding of your application:

- For achieving ultimate material purity: We don't just provide a high-vacuum pump. We pair it with the right non-reactive heating elements (like molybdenum or tungsten), select insulation materials with low outgassing rates, and engineer a leak-proof chamber to create a holistically clean environment.

- For manufacturing high-density composites: We don't just increase pressure. We design a robust pressing mechanism and integrate it with a heating system specifically configured for exceptional thermal uniformity under load, ensuring even compaction without defects.

- For ensuring process repeatability: We build sophisticated PLC control systems that don't just manage individual parameters, but orchestrate the seamless interplay between them, executing your recipe with precision, batch after batch.

A KINTEK furnace is not an off-the-shelf product; it's a purpose-built solution designed from the ground up to solve your specific material challenge.

From Fighting Your Furnace to Fueling Innovation

When your equipment stops being an unpredictable variable, a profound shift occurs. Your team's energy is no longer consumed by troubleshooting and re-running failed experiments. Instead, that intellectual capital is freed to do what it does best: innovate.

With a truly integrated and reliable vacuum hot press system, you can:

- Accelerate R&D cycles by getting trustworthy, repeatable data on the first try.

- Explore more ambitious materials and processes, confident that your equipment can meet the challenge.

- Scale from lab to pilot production seamlessly, knowing your results are reproducible.

- Commit to customer deadlines and production targets with certainty, building a reputation for reliability.

Ultimately, solving the problem of system imbalance isn't just about getting better samples. It's about unlocking your lab's full potential to develop the next generation of advanced materials.

Your material processing challenges are unique. Your furnace should be too. Stop battling a system in conflict and let our team design a solution where every component works in unison to achieve your goals. To discuss the specific requirements of your project, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

Related Articles

- Why Your Sintered Parts Fail: It’s Not Just About Heat, But Pressure and Purity

- How to Select the Right Vacuum Hot Pressing Furnace Temperature for Your Materials

- Why Your High-Temperature Materials Fail: The Hidden War Inside Your Furnace

- Your Vacuum Furnace Is a System, Not a Component—Here’s Why That Changes Everything

- How Vacuum Hot Press Furnaces Transform Advanced Material Engineering