It’s a familiar story for many labs and production floors. The pressure gauge on your vacuum furnace is fluctuating, refusing to settle at the target millitorr. The high-temperature process you’ve carefully designed—be it distillation, brazing, or sintering—yields another inconsistent result. You've spent hours, maybe even days, leak-checking fittings and questioning your raw materials. The project deadline is creeping closer, but you're stuck fighting your equipment instead of advancing your work.

This isn't just a minor inconvenience; it's a critical bottleneck that burns through time, materials, and budget.

The Vicious Cycle: Bigger Pumps, More Sealant, Same Bad Results

When faced with an unstable vacuum, the knee-jerk reaction is often to treat the most obvious part: the pump. The logic seems sound: if the pressure isn't low enough, we must need more pumping power. This leads down a well-trodden but ultimately frustrating path:

- "Let's upgrade to a more powerful pump." You invest in a larger backing pump or a high-end turbo-molecular pump, expecting it to brute-force the system into submission. Yet, the instability persists.

- "It must be a leak." The team spends a day applying vacuum grease to every conceivable joint, creating a temporary, messy fix that often masks the real issue.

- "We'll just pump down for longer." You extend the evacuation time, hoping to pull out every last molecule of air before the heating cycle begins. The initial vacuum looks good, but as soon as the temperature starts to ramp, the pressure spikes.

Each of these "solutions" fails to deliver repeatable results because they are based on a fundamental misunderstanding. They treat the vacuum system as a simple component, like a shop vac for a furnace.

The commercial consequences are severe. R&D timelines stretch from weeks into months. Production batches are scrapped due to contamination or incomplete reactions, driving up costs per unit. Most critically, the inability to guarantee a stable process environment erodes confidence in your product's quality and reliability.

The Real Culprit: A Battle Between Heat and Hidden Gas

The reason these fixes fail is that a vacuum furnace is not just a sealed chamber with a pump attached. It is a dynamic environment where multiple forces are in constant, delicate balance. The true problem isn't a lack of power; it's a lack of system-level control.

Here’s the underlying science that most component-based solutions ignore:

1. The Multi-Stage Evacuation Process

A vacuum isn't created in one step. First, a backing pump (the workhorse) does the "heavy lifting," removing over 99.9% of the air to create a rough vacuum. Only then can a high-vacuum pump (the specialist, like a turbo or diffusion pump) take over to achieve the extremely low pressures needed for sensitive processes. Using the wrong pump at the wrong time, or having an imbalanced pair, is like trying to paint a detailed portrait with a house-painting roller. It's simply the wrong tool for the job.

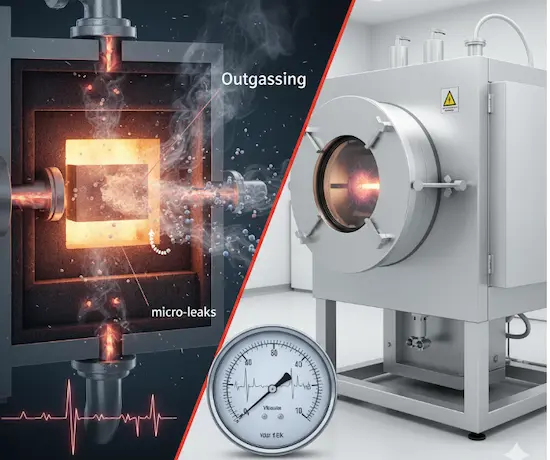

2. The Unseen Enemy: Outgassing

When you heat materials—any materials, including the furnace insulation, fixtures, and your product itself—under vacuum, they release trapped gases and water vapor. This phenomenon is called outgassing. Your initial, pre-heat vacuum reading might be perfect, but the moment your temperature ramp begins, this outgassing floods the chamber with new gas molecules. A system that isn't designed to handle this dynamic gas load will inevitably fail, as the pump struggles to remove gas as fast as it's being released.

3. The Constant Threat: Micro-Leaks

A powerful pump fighting a microscopic leak is like trying to fill a bucket with a hole in it. You can pour water in faster, but it will never be stable. In a vacuum system, high-integrity seals, precision-machined flanges, and expert assembly are non-negotiable.

Simply bolting a powerful pump onto a poorly integrated chamber doesn't solve these systemic issues. It only masks them temporarily, leading to the maddening inconsistency you're trying to escape.

The Solution: A System Engineered for Stability

To achieve repeatable, reliable results, you must shift your perspective from buying parts to investing in an integrated system. You need a furnace where the chamber, pumps, gauges, and controls are not just assembled, but are engineered to work in concert.

This is where a purpose-built solution becomes critical. At KINTEK, our Vacuum & Atmosphere Furnaces are designed based on a deep understanding of this interplay. They are not a collection of third-party components, but a cohesive system born from in-house R&D and manufacturing.

- For the Multi-Stage Process: We precisely match backing pumps and high-vacuum pumps (whether you need an oil-free turbo-molecular pump for ultimate purity or a robust diffusion pump for throughput) to the chamber volume and your specific process requirements. The system works as a balanced, efficient unit from the start.

- To Combat Outgassing: Our advanced control systems allow you to program sophisticated recipes that synchronize temperature ramps with vacuum levels. This enables the system to manage outgassing intelligently, holding at certain temperatures to allow gases to escape before proceeding, ensuring the pressure remains stable when it matters most.

- To Eliminate Leaks: Leveraging our in-house manufacturing, we control the quality of every weld, flange, and seal. Our chambers are designed and built for vacuum integrity, providing a stable foundation that a piecemeal system can't replicate.

Our deep customization capability means we architect the entire system around your goal—whether it's achieving the highest purity, the fastest cycle time, or the flexibility to handle multiple processes.

Beyond Troubleshooting: Unlocking New Process Potential

When your vacuum furnace transforms from a source of frustration into a reliable, predictable tool, the entire dynamic of your work changes. The hours spent troubleshooting are converted back into hours spent on innovation.

With a stable and repeatable process, you can now:

- Accelerate R&D Cycles: Move confidently from one experiment to the next, knowing the equipment is a constant, not a variable.

- Improve Product Quality & Yield: Eliminate batch-to-batch variation, leading to higher-quality products and less wasted material in a production environment.

- Explore New Frontiers: Tackle more advanced materials and processes that demand stricter and more complex atmospheric control, opening up new commercial or scientific opportunities.

You can finally stop fighting your tools and start leveraging them to achieve your objectives.

Your high-temperature process is too critical to be left to chance. If you're ready to move past the cycle of instability and unlock the full potential of your work, it’s time to look at the system as a whole. Our team doesn't just sell furnaces; we partner with you to engineer solutions for complex thermal processing challenges. Let's discuss the specific requirements of your project and design a system that delivers the stability and performance you need. Contact Our Experts.

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

Related Articles

- From Brute Force to Perfect Control: The Physics and Psychology of Vacuum Furnaces

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection

- The Pursuit of Purity: Why a Vacuum Furnace Is a System for Creating Certainty

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites