You’ve done everything right. You spent weeks meticulously preparing a new, high-purity alloy. The vacuum hot press cycle completes, the alarms are silent, and you pull out a sample that looks physically perfect. But then, the post-processing analysis comes back, and your heart sinks. The material is brittle, its mechanical properties are all over the map, and it's completely unusable for its intended application. Weeks of work and thousands of dollars in materials—gone. You’re left staring at the furnace, wondering which setting you got wrong.

Chasing Ghosts: Why Tweaking Settings Isn't the Answer

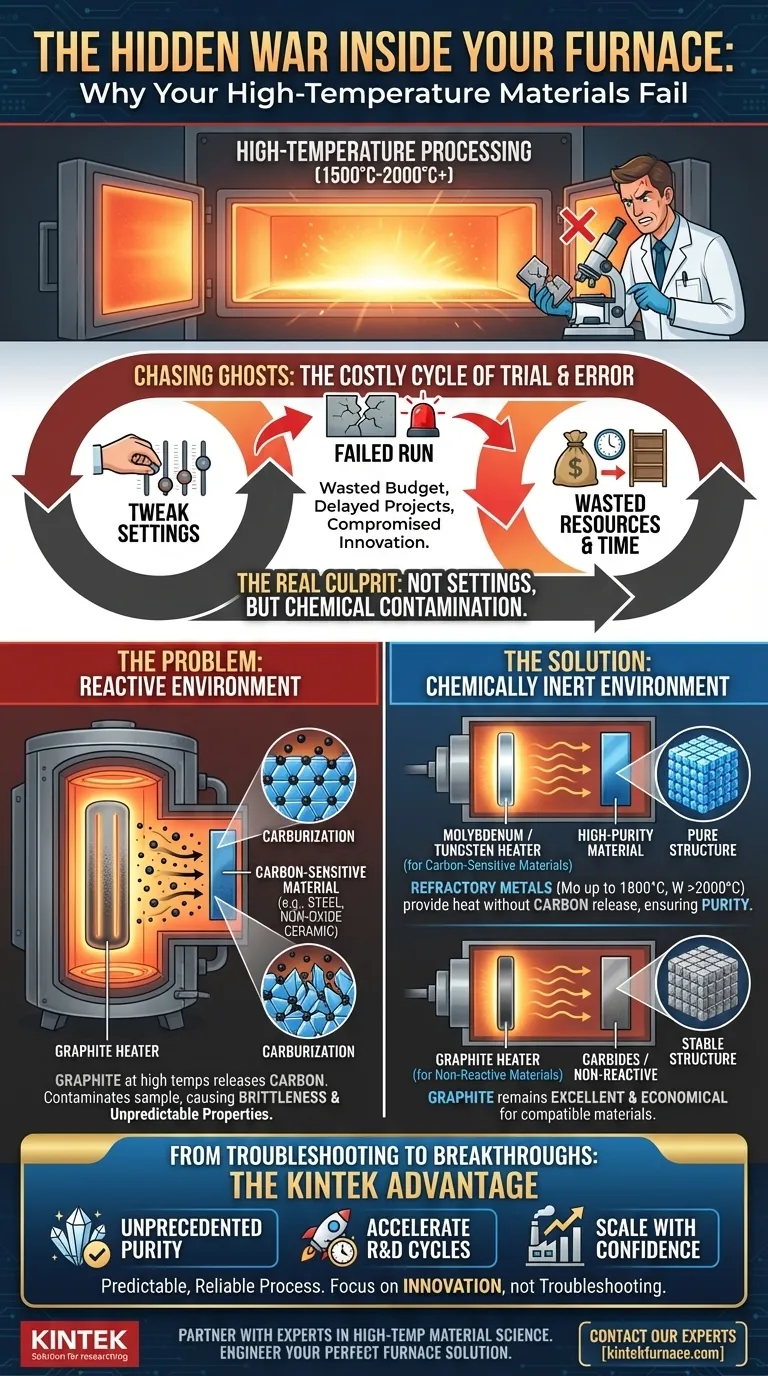

This scenario is frustratingly common in advanced materials labs and production facilities. When faced with inconsistent results, the natural instinct is to start tweaking the parameters. "Maybe we need a longer soak time," the team suggests. "Let's try increasing the pressure," another proposes. "Perhaps a slower ramp rate will fix it."

So begins a costly and time-consuming cycle of trial and error. Each failed run carries significant consequences:

- Wasted Resources: High-purity metals, advanced ceramics, and composite powders are expensive. Every failed batch is a direct hit to the R&D budget.

- Delayed Timelines: Projects stall as your team gets bogged down in troubleshooting the process instead of advancing the research or production.

- Compromised Innovation: Promising new materials are abandoned because the team can't achieve a repeatable manufacturing process, killing innovation before it can even start.

These "solutions" rarely work because they are based on a flawed assumption. They assume the furnace is a passive box that simply applies heat and pressure. The reality is far more complex.

The Real Culprit: A High-Temperature Chemical Reaction

Here is the fundamental truth that many overlook: at processing temperatures of 1500°C, 2000°C, or higher, your furnace is not a sterile environment. It is a reactive chemical chamber.

The problem isn't your temperature profile or pressure settings. The problem is that your heating element—the very source of the energy—is actively contaminating your sample.

The Hidden Contamination Source

Consider the most common and cost-effective heating element: graphite. For many applications, like sintering carbides, it's an excellent choice. But if you are processing a carbon-sensitive material, such as a specialized steel alloy or a non-oxide ceramic, a disastrous chemical reaction is occurring:

- At extreme temperatures, the graphite heater begins to release microscopic carbon particles.

- In the vacuum environment, these carbon atoms travel and embed themselves directly into the surface and structure of your sample.

- Your high-purity, carefully formulated material is now contaminated with unwanted carbon, a process called carburization. This fundamentally alters its crystalline structure, making it brittle and unpredictable.

This is why changing the settings fails. You’ve been trying to solve a materials science problem by adjusting the machine's controls, when the root cause is a fundamental chemical incompatibility between the furnace's core components and your workpiece.

Beyond Heat: Engineering a Chemically Inert Environment

To truly solve this problem, you don't need to endlessly tweak your process; you need to control the chemical environment. This requires a furnace that is not just a heater, but a precisely engineered system designed with a deep understanding of high-temperature material science.

The solution is to select a heating element that is chemically inert to your specific material.

- For Carbon-Sensitive Metals and Ceramics: Refractory metals like molybdenum (up to 1800°C) or tungsten (above 2000°C) are the ideal choice. They provide exceptional heat without releasing carbon, ensuring your material's purity remains intact.

- For Non-Reactive Materials or Carbides: Graphite remains an excellent, economical option, delivering robust performance when chemical compatibility is not a concern.

This is the design philosophy behind KINTEK's furnace solutions. We recognize that one size does not fit all. Our expertise isn't just in building machines that get hot; it's in creating the perfect, non-reactive environment for your specific application. Our deep customization capability means we work with you to select the precise heating element, insulation, and chamber materials that guarantee chemical compatibility, eliminating contamination as a variable in your process.

From Troubleshooting to Breakthroughs: The Power of a Predictable Process

When you eliminate the hidden variable of chemical contamination, the entire dynamic of your work changes. The furnace ceases to be a source of frustration and becomes a reliable, predictable tool for innovation.

With a furnace correctly matched to your material, you unlock new possibilities:

- Achieve Unprecedented Purity: Develop next-generation alloys and composites with the confidence that their properties won't be compromised by the processing environment.

- Accelerate R&D Cycles: Move seamlessly from concept to validated prototype without months of troubleshooting. Your first run becomes your best run.

- Scale with Confidence: Transition from lab-scale experiments to full production, knowing that your material properties will remain consistent batch after batch, ensuring high yields and product reliability.

Ultimately, solving the "hidden war" inside your furnace frees up your most valuable assets—your time, budget, and expert personnel—to focus on what they do best: pushing the boundaries of material science and creating what's next.

Solving your high-temperature processing challenges is about more than just hardware; it's about partnering with experts who understand the intricate science behind your work. If you're tired of battling inconsistent results and want to build a truly reliable and repeatable process, our team is ready to help you engineer the perfect furnace solution for your unique materials. Let's discuss the specific demands of your project. Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Related Articles

- The Real Reason Your High-Performance Materials Are Failing (And It’s Not the Alloy)

- How to Select the Right Vacuum Hot Pressing Furnace Temperature for Your Materials

- Why Your High-Purity Metals Oxidize in a Perfect Vacuum—And How to Stop It

- Beyond the Parts List: The Real Reason Your Vacuum Hot Press Fails (And How to Fix It)

- Your Furnace Reached Temperature. So Why Did Your Experiment Fail?