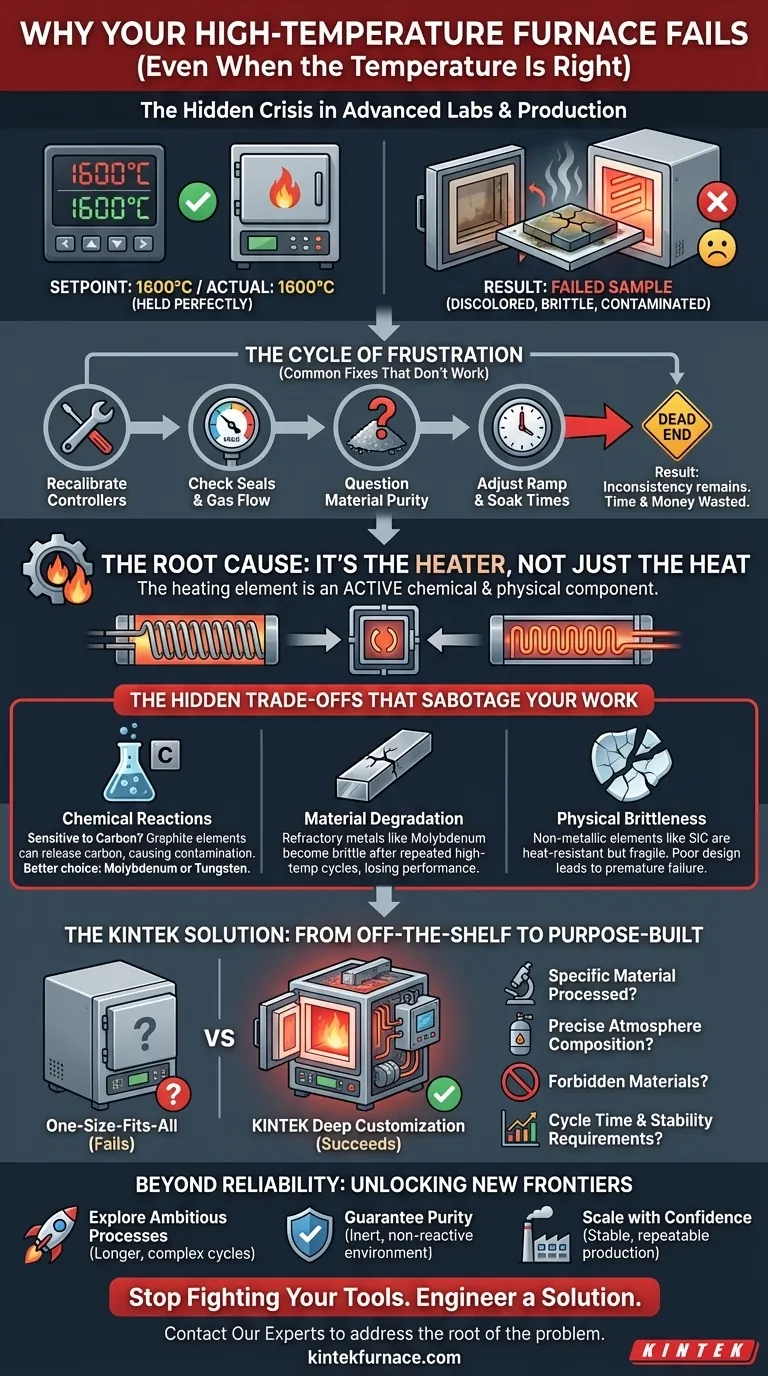

The alarm on your high-temperature furnace signals the end of a critical 12-hour cycle. You open the chamber, expecting a perfectly sintered component or a pristine crystal, only to find your sample discolored, brittle, or contaminated.

Your data is unusable. A week's work is lost. And you're left with a frustrating question: "The controller shows it held the setpoint perfectly. What went wrong?"

If this scenario feels familiar, you're not alone. It's a quiet crisis playing out in advanced laboratories and production facilities every day.

The Cycle of Frustration: Why Common Fixes Don't Work

When faced with inconsistent results, the first instinct is to troubleshoot the obvious. Engineers and researchers begin a familiar, time-consuming ritual:

- Recalibrating temperature controllers.

- Checking vacuum seals and gas flow rates.

- Questioning the purity of the raw materials.

- Adjusting ramp rates and soak times.

Each attempt is a logical step, but they often lead to the same dead end. The inconsistency remains, a phantom in the machine.

This isn't just an academic puzzle; it has severe business consequences. Project timelines stretch from weeks into months. The cost of wasted high-purity materials and energy skyrockets. Most importantly, a lack of process reliability can erode confidence in research findings or, in a production setting, lead to catastrophic failures in product quality and yield. You're left treating symptoms, while the real disease remains undiagnosed.

The Root Cause: It's Not Just the Heat, It's the Heater

Here is the fundamental truth that many overlook: a furnace's heating element is not just a passive source of heat. It is an active chemical and physical component within your process environment. The failure isn't in your furnace's ability to get hot, but in a fundamental mismatch between the heating element's material and the specific demands of your application.

Think of it this way: simply choosing a furnace rated for 2000°C is like choosing a vehicle based only on its top speed, without considering whether you'll be driving on a racetrack, a mountain road, or through a desert. The environment dictates the right choice.

The Hidden Trade-offs That Sabotage Your Work

The source article outlines a clear temperature-based guide for materials—Nickel-Chromium for lower temperatures, Molybdenum or SiC for the mid-range, and Graphite or Tungsten for extreme heat. But the critical insight lies in the trade-offs:

- Chemical Reactions: Are you running a process sensitive to carbon? Using a standard Graphite element, even at the correct temperature, can release trace amounts of carbon, causing carburization that contaminates your sample. In this case, a metallic element like Molybdenum or Tungsten would have been the superior, though less obvious, choice.

- Material Degradation: Refractory metals like Molybdenum are robust, but they can become brittle after repeated high-temperature thermal cycles. If your furnace is slowly losing performance, the element itself might be degrading, unable to deliver consistent thermal output.

- Physical Brittleness: Non-metallic elements like Silicon Carbide offer fantastic temperature resistance but are more fragile. A design that doesn't account for their physical properties can lead to premature failure and costly downtime.

The "common fixes" like recalibrating controllers fail because they can't change physics. You can't program your way around a chemical incompatibility. The problem isn't in the furnace's brain; it's in its bones.

From Off-the-Shelf to Purpose-Built: The Right Tool for the Job

To permanently solve this problem, you need to shift your perspective. The goal isn't to buy a furnace that can reach a temperature; it's to acquire a thermal processing tool that is engineered for your specific application's chemistry, atmosphere, and lifecycle.

This is where a one-size-fits-all approach fails and a philosophy of deep customization becomes essential. To achieve true reliability, the heating element and hot zone materials must be the starting point of the furnace design, not an afterthought.

This is precisely how KINTEK approaches the challenge. Our strength isn't just in building a diverse range of furnaces—from Tube and Muffle to advanced CVD systems—but in our in-house R&D and manufacturing that enables deep customization. We don't just ask, "How hot do you need to go?" We ask:

- What specific material are you processing?

- What is the precise atmospheric composition?

- Are there any materials that absolutely cannot be present in the chamber?

- What are your requirements for cycle time and long-term stability?

By starting with these questions, we design and build a furnace where the heating element is a perfect match for your process. The result is a tool that isn't just capable of reaching the target temperature, but is designed to deliver precise, repeatable, and contamination-free results, cycle after cycle. It's a solution born from a deep understanding of the root cause.

Beyond Reliability: Unlocking New Frontiers

When your furnace transforms from an unpredictable variable into a reliable, trusted instrument, everything changes. The focus shifts from troubleshooting equipment to accelerating innovation.

With a purpose-built KINTEK furnace, you can:

- Explore Ambitious Processes: Confidently run longer, more complex thermal cycles required for developing next-generation materials.

- Guarantee Purity: Work with ultra-sensitive materials, knowing the furnace environment is inert and non-reactive.

- Scale with Confidence: Seamlessly move from R&D to production with a process that is fundamentally stable and repeatable, drastically improving yield and time-to-market.

You stop wasting time and resources fighting your tools and start pushing the boundaries of what's possible.

Your work is too important to be compromised by a hidden material mismatch. If you're tired of battling inconsistent results and want to build a thermal process you can truly depend on, let's talk about the specific challenges of your project. Our team is ready to help you engineer a solution that finally addresses the root of the problem. Contact Our Experts.

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace