Thermal Elements

Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

Item Number : KT-MH

Price varies based on specs and customizations

- Maximum Operating Temperature

- 1800°C (1900°C in specific oxidizing atmospheres)

- Oxidation Resistance

- Forms protective SiO2 layer at high temperatures

- Available Shapes

- Straight, U-shaped, W-shaped, L-shaped

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

High-Performance Molybdenum Disilicide (MoSi2) Heating Elements

KINTEK, leveraging exceptional R&D and in-house manufacturing, provides advanced Molybdenum Disilicide (MoSi2) Heating Elements, integral to our high-temperature furnace solutions for diverse laboratories. These elements are engineered for superior performance, reliability, and longevity in the most demanding thermal environments, ensuring your experiments and processes achieve optimal results.

Product Showcase: MoSi2 Heating Elements

Our MoSi2 heating elements are available in various configurations to suit your specific furnace and application needs. See the quality and versatility firsthand:

Key Features & Benefits: Why Choose KINTEK MoSi2 Elements?

KINTEK's MoSi2 Heating Elements are renowned for their exceptional performance, offering significant advantages for your high-temperature applications:

- Extreme Temperature Capability: Operate efficiently at temperatures up to 1800°C (and even 1900°C in specific oxidizing atmospheres), ideal for processes requiring intense heat. The maximum operating temperature under an oxidation atmosphere is 1800 ℃.

- Superior Oxidation Resistance: When heated in an oxidizing atmosphere, a protective, dense silica (SiO2) glass film forms on the surface. This layer safeguards the inner MoSi2 material from further oxidation, ensuring unique high-temperature oxidation resistance and extended element life.

- Stable and Reliable Performance: The resistance of MoSi2 elements increases with temperature, stabilizing when the temperature is constant. This stable resistance allows for consistent heating and the ability to connect new and old elements in series without compromising performance.

- Long Service Life: With proper selection of surface load and operating conditions, our MoSi2 elements offer the longest inherent life among many electric heating elements, providing a cost-effective solution by minimizing replacements and maintenance.

- Resilience to Thermal Cycling: These elements can withstand rapid thermal cycling without significant degradation, crucial for processes involving frequent temperature changes.

- Ease of Replacement: Designed for convenience, MoSi2 elements can often be replaced even while the furnace is hot, minimizing operational downtime.

- Versatile Shapes & Customization: Available in standard straight, U-shaped, W-shaped, L-shaped configurations. Backed by KINTEK's strong deep customization capability, we can tailor elements to precisely meet your unique experimental requirements and furnace designs.

Wide Range of Applications

Molybdenum disilicide (MoSi2) heaters are vital in numerous high-temperature fields. Their robust performance makes them suitable for:

- High-Temperature Furnace Operations: Essential for furnaces used in producing ceramics, glass, and metals, reaching up to 1800°C.

- Laboratory Research: Widely employed in laboratory furnaces for materials testing, synthesis, and research at high temperatures.

- Industrial Processing: Integral to processes like sintering, annealing, and heat treatment of various materials.

- Advanced Materials Manufacturing: Used in the production of high-performance precision ceramics, high-grade artificial crystals, precision structural metal ceramics, glass fibers, optical fibers, and high-grade alloy steel.

- Semiconductor Manufacturing: Applied in fabrication processes where precise high-temperature control is critical.

They are widely used in metallurgy, steel making, refractories, crystal and electronic component manufacturing, and other fields demanding high-temperature precision.

Customized Solutions & Expert Support

At KINTEK, we understand that unique experimental requirements demand tailored solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability. We can integrate these high-performance MoSi2 heating elements into your existing setup or as part of a new, custom-designed furnace solution.

Ready to enhance your high-temperature processes? Our experts are here to help you select or customize the ideal MoSi2 heating elements for your application. Contact us today via our Contact Form to discuss your specific needs and let KINTEK power your innovations.

Technical Specifications

Chemical Properties & Oxidation Resistance

As highlighted, Molybdenum Disilicide heating elements exhibit exceptional high-temperature oxidation resistance. The formation of a bright and dense silica (SiO2) glass film on the surface in oxidizing atmospheres protects the inner core, ensuring longevity and stable operation at high temperatures.

Physical Properties

| Physical Properties (g/cm³) | Bending Strength (MPa) | Hardness (GPa) | Compression Strength (MPa) | Water Absorption (%) | Heated Elongation (%) |

|---|---|---|---|---|---|

| 6.0±0.1 | 500 | 12 | >1500 | ≤0.2% | 4 |

Working Performance in Different Atmospheres (Max. Element Temperature °C)

| Atmosphere | T1700 Grade | T1800 Grade | T1850 Grade | T1900 Grade |

|---|---|---|---|---|

| Air | 1700 | 1800 | 1830 | 1850 |

| N2 Nitrogen | 1600 | 1700 | 1700 | 1700 |

| Ar, He (Argon, Helium) | 1600 | 1700 | 1700 | 1700 |

| Dry Hydrogen (dew point -80℃) | 1150 | 1150 | 1150 | 1150 |

| Wet Hydrogen (dew point -20℃) | 1450 | 1450 | 1450 | 1450 |

| Exogas (e.g., 10% CO2, 50% CO, 15%H2) | 1600 | 1700 | 1700 | 1700 |

| Exogas (e.g., 40% CO2, 20% CO) | 1400 | 1450 | 1450 | 1450 |

| Cracked and partially burnt ammonia | 1400 | 1450 | 1450 | 1450 |

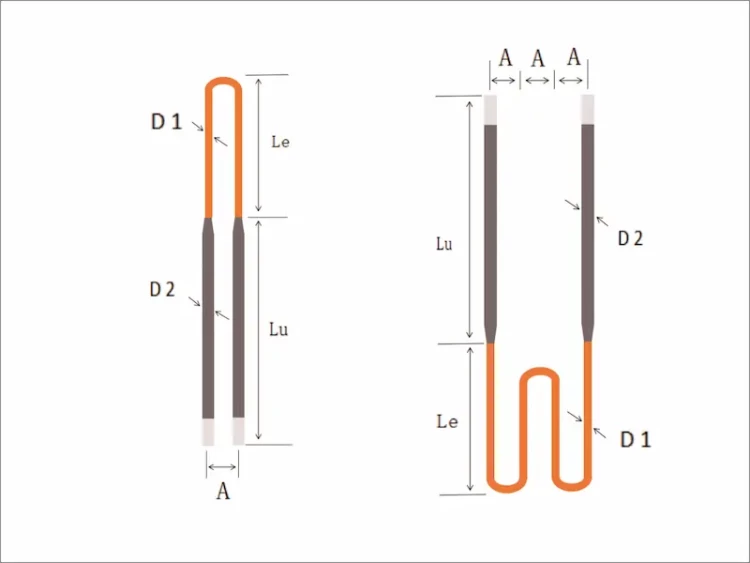

Understanding MoSi2 Element Models & Dimensions

To specify the correct MoSi2 heating element, please refer to the following model marking convention:

- D1: Hot zone diameter

- D2: Cold zone diameter

- Le: Hot zone length

- Lu: Cold zone length

- A: Gap distance (shank spacing)

Standard model number format: D1/D2*Le*Lu*A

For example: If D1=6mm, D2=12mm, Le=200mm, Lu=300mm, A=30mm, the model is specified as: 6/12*200*300*30mm

Commonly available dimensions (custom sizes available upon request):

| D1 | D2 | Le Range | Lu Range | A (Typical) |

|---|---|---|---|---|

| 3mm | 6mm | 80-300mm | 80-500mm | 25mm |

| 4mm | 9mm | 80-350mm | 80-500mm | 25mm |

| 6mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 7mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 9mm | 18mm | 100-1200mm | 100-2500mm | 40-80mm |

| 12mm | 24mm | 100-1500mm | 100-1500mm | 40-100mm |

Installation Guidance

For optimal performance and longevity of your MoSi2 heating elements, proper installation is crucial. Please click here for precautions and best practices when installing MoSi2 heating elements.

FAQ

What Are The Main Applications Of Heater Elements Like MoSi2 And SiC?

What Are The Advantages Of Using MoSi2 Heating Elements?

What Are The Benefits Of SiC Heating Elements?

Why Are Ceramic And Semiconductor Heating Elements Like MoSi2 And SiC Suitable For High-temperature Environments?

Can MoSi2 And SiC Heating Elements Be Customized?

4.9 / 5

Incredible durability and performance! These heating elements are a game-changer for our lab.

4.8 / 5

Fast delivery and top-notch quality. Worth every penny!

4.7 / 5

The efficiency of these elements is unmatched. Highly recommend!

4.9 / 5

Perfect for high-temperature applications. Excellent value for money.

4.8 / 5

Superior technology and long-lasting. A must-have for any electric furnace.

4.9 / 5

These elements heat up quickly and maintain temperature flawlessly.

4.7 / 5

Impressive build quality and reliable performance. Very satisfied!

4.8 / 5

Great investment for our industrial needs. Works like a charm.

4.9 / 5

The best heating elements we've used. Consistent and efficient.

4.7 / 5

Excellent thermal stability and longevity. Highly recommended!

4.8 / 5

Fast shipping and exceptional product. Exceeded our expectations.

4.9 / 5

Perfect for precision heating. These elements are a cut above the rest.

4.8 / 5

Reliable and efficient. A fantastic addition to our equipment.

4.7 / 5

High-quality materials and superb performance. Very pleased!

4.9 / 5

These elements are worth every cent. They deliver consistent results.

4.8 / 5

Outstanding product with fast delivery. Perfect for our needs.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Molybdenum Vacuum Heat Treat Furnace

High-performance molybdenum vacuum furnace for precise 1400°C heat treatment. Ideal for sintering, brazing, and crystal growth. Durable, efficient, and customizable.

Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

KINTEK's Rotary Biomass Pyrolysis Furnace converts biomass to biochar, bio-oil, and syngas efficiently. Customizable for research or production. Get your solution now!

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

High-performance SiC heating elements for labs, offering 600-1600°C precision, energy efficiency, and long lifespan. Customizable solutions available.

MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

KINTEK MPCVD Systems: Precision diamond growth machines for high-purity lab-grown diamonds. Reliable, efficient, and customizable for research and industry.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

Premium KF/ISO stainless steel vacuum blind plates for high-vacuum systems. Durable 304/316 SS, Viton/EPDM seals. KF & ISO connections. Get expert advice now!

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

CF Ultra-High Vacuum Observation Window Flange with high borosilicate glass for precise UHV applications. Durable, clear, and customizable.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Vacuum Heat Treat Sintering and Brazing Furnace

KINTEK Vacuum Brazing Furnaces deliver precision, clean joints with superior temperature control. Customizable for diverse metals, ideal for aerospace, medical, and thermal applications. Get a quote!

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Related Articles

Why Your High-Temperature Furnace Fails (Even When the Temperature Is Right)

Discover why your high-temp experiments fail despite correct settings. Learn how the heating element material—not just temperature—is the key to success.

Purity Under Pressure: The Materials Science of a Vacuum Furnace Hot Zone

Explore the engineering trade-offs between molybdenum and graphite in a vacuum furnace's hot zone, revealing how material choices dictate process purity and performance.

The Heart of the Void: Choosing the Right Heating Element for Your Vacuum Furnace

Learn the critical trade-offs between graphite and refractory metals when selecting a vacuum furnace heating element for temperature, purity, and cost.

The Unseen Battle: Containing Molten Magnesium and the Quest for Purity

Discover why corundum's inertness and thermal stability make it the only choice for preventing contamination in high-temperature metal experiments.

The Invisible Battle: Material Science in High-Temperature Magnesium Evaporation

Molten magnesium's extreme reactivity demands chemically inert crucibles like high-purity alumina to prevent catastrophic contamination and ensure purity.