MPCVD

MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

Item Number : KTMP315

Price varies based on specs and customizations

- Microwave power

- 1~10 kW

- Substrate growing area

- 3-inch

- Maximum batch load

- 45 diamond pieces

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Elevate Your Diamond Synthesis with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK delivers cutting-edge Microwave Plasma Chemical Vapor Deposition (MPCVD) systems. Our machines are meticulously designed for reliability, efficiency, and the consistent production of high-purity, high-quality diamonds, catering to diverse laboratory and industrial needs.

Why KINTEK MPCVD Systems Are Your Premier Choice

At KINTEK, we are committed to advancing diamond synthesis technology. Our MPCVD systems offer a compelling combination of performance, innovation, and support:

- Unmatched Reliability & Performance: With documented operational stability exceeding 40,000 hours, our MPCVD equipment sets the industry standard for reliability, repeatability, and cost-effectiveness. You can trust KINTEK systems for consistent results, run after run.

- Advanced Technological Edge: We continuously reinvest in R&D, implementing multiple upgrades and improvements. This commitment translates to MPCVD systems with significantly improved efficiency and reduced operational costs for our clients.

- Key System Advantages:

- Spacious Growth Area: Features a 3-inch substrate growing area, accommodating a maximum batch load of up to 45 diamond pieces.

- Energy Efficiency: Equipped with 1-10kW adjustable output microwave power, minimizing electricity consumption without compromising performance.

- Expert Knowledge Transfer: Benefit from the support of our richly experienced research team, including access to frontier diamond growing recipes.

- Comprehensive Support for All Users: We offer an exclusive technical support program, empowering even teams with zero prior diamond growing experience to achieve success.

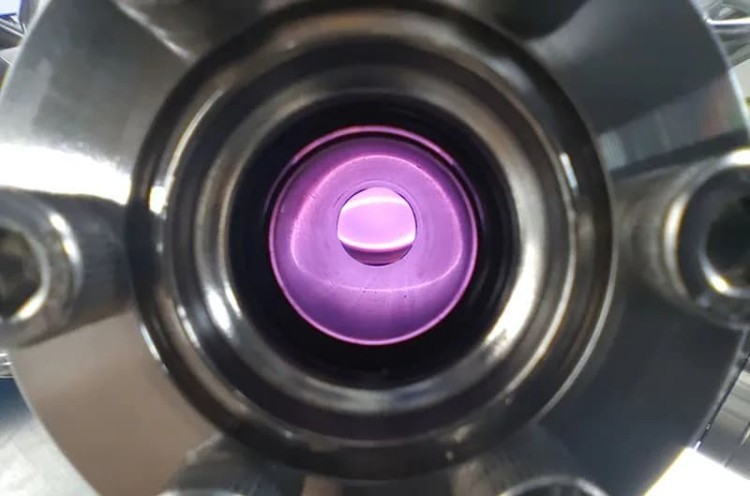

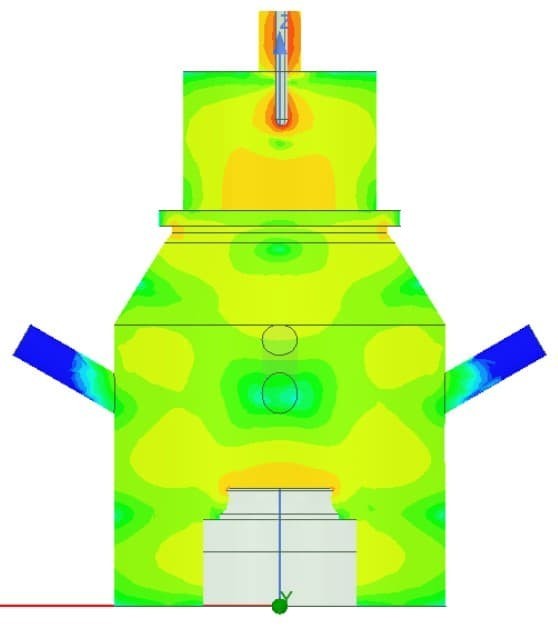

Visual Showcase: The KINTEK MPCVD Advantage in Action

See the remarkable results and precision engineering of our MPCVD technology:

Understanding MPCVD Technology

MPCVD (Microwave Plasma Chemical Vapor Deposition) is an advanced technique for synthesizing high-quality diamond films and single crystals. It involves creating a microwave-generated plasma from carbon-containing gases (like methane, CH4) mixed with other gases (such as H2, Ar, O2, N2) within a vacuum chamber. This plasma facilitates the precise deposition of carbon atoms onto a substrate, allowing for the controlled growth of diamond material.

General Advantages of the MPCVD Method:

Compared to other synthesis techniques like High-Pressure High-Temperature (HPHT), MPCVD offers several key advantages:

- Higher Purity Diamonds: The non-contact plasma and controlled environment minimize contamination.

- Lower Energy Consumption: Generally more energy-efficient than HPHT.

- Potential for Larger Diamonds: Well-suited for growing larger single crystal diamonds and extensive films.

- Versatile Gas Control: Allows for the use of multiple gases, offering flexibility in tuning diamond properties.

- Stable Processing: Offers smooth microwave power adjustment and stable temperature control, crucial for consistent quality and avoiding issues like seed crystal loss.

These characteristics make MPCVD a promising and widely adopted method for industrial applications and advanced research, particularly where high quality and controlled growth are paramount.

Diverse Applications, Unlocked by KINTEK MPCVD

KINTEK's MPCVD systems are engineered to meet the demands of various cutting-edge applications, leveraging diamond's unique properties such as exceptional hardness, high stiffness, superior thermal conductivity, low thermal expansion, radiation-hardness, and chemical inertness:

- Lab-Grown Gemstones: Producing large, high-quality diamonds for the jewelry market at a competitive cost, offering an ethical and sustainable alternative.

- Semiconductor Industry: Enabling the growth of large-area, high-purity diamond substrates crucial for next-generation power electronics, quantum computing, and advanced sensors.

- Optical Components: Creating diamond films and windows with superior optical transmission, thermal stability, and durability for lasers and other optical systems.

- Industrial Tools: Manufacturing highly durable diamond-coated cutting, drilling, and grinding tools for machining hard and abrasive materials.

- Research & Development: Providing a versatile and reliable platform for academic and industrial researchers exploring new diamond materials, doping techniques, and applications.

Our MPCVD technology offers a significant advantage over traditional HPHT methods, especially for applications requiring large-sized, high-purity diamonds. This positions KINTEK systems as an ideal solution for the semiconductor, optics, and modern jewelry markets, driving innovation and enabling new possibilities.

In-Depth: KINTEK MPCVD System Design & Operation

How Our MPCVD Systems Work (Working Process)

The KINTEK MPCVD machine meticulously controls the flow of each gas path (reactant gases such as CH4, H2, Ar, O2, N2, etc.) and cavity pressure. Gases are introduced into the cavity under specific, recipe-defined pressures. After stabilizing the airflow, a 6KW (or other specified power) solid-state microwave generator produces microwaves, which are then guided into the cavity through a waveguide.

Within the microwave field, the reaction gas transforms into a plasma state, forming a stable plasma ball that hovers precisely above the diamond substrate. The intense heat from the plasma raises the substrate to the optimal growth temperature. Excess heat generated within the cavity is efficiently dissipated by an integrated water-cooling unit.

To ensure optimal growth conditions during the MPCVD single crystal diamond growth process, operators can precisely adjust factors such as microwave power, gas source composition, and cavity pressure. A key advantage is that the plasma ball does not contact the cavity wall, ensuring the diamond growth process is free from impurities, thereby significantly enhancing the diamond's quality and purity.

System Components & Details

Microwave system

Reaction chamber

Gas flow system

Vacuum and sensor system

Comprehensive Technical Specifications

| Microwave system |

|

| Reaction chamber |

|

| Sample holder |

|

| Gas flow system |

|

| Cooling system |

|

| Temperature sensor |

|

| Control system |

|

| Optional function |

|

Partner with KINTEK for Your Advanced Material Needs

KINTEK is a recognized leader in providing advanced high-temperature furnace solutions, backed by exceptional R&D capabilities and dedicated in-house manufacturing. Our extensive product line, which includes Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD/MPCVD Systems, is a testament to our comprehensive expertise in thermal processing and material science. We pride ourselves on our strong deep customization capability, allowing us to precisely meet your unique experimental or industrial production requirements.

Ready to Revolutionize Your Diamond Production or Research?

Discover how KINTEK's advanced MPCVD systems can elevate your capabilities. Whether you are focused on gemstone production, semiconductor materials, optical components, or pioneering research, our team of experts is here to help you find the perfect solution. We offer personalized consultation, detailed specifications, and custom-built systems tailored to your needs.

Contact Us Today to discuss your project, request a quote, or learn more about how KINTEK can empower your success in diamond synthesis!

FAQ

What Is The Principle Of An MPCVD Machine?

What Are The Advantages Of Using An MPCVD Machine?

What Are The Key Applications Of MPCVD Machines?

What Are The Main Components Of An MPCVD Machine?

How Does An MPCVD Machine Enhance Energy Efficiency?

Why Is MPCVD Preferred For Diamond Growth?

4.9 / 5

Incredible precision and speed! Our lab's diamond growth has never been more efficient. Worth every penny!

4.8 / 5

Top-notch quality and durability. This machine is a game-changer for our research projects.

4.7 / 5

Fast delivery and easy setup. The technological advancement in this system is mind-blowing!

4.9 / 5

Exceptional value for money. The bell-jar resonator performs flawlessly under high pressure.

4.8 / 5

Reliable and robust. Perfect for continuous lab use without any hiccups.

4.9 / 5

Cutting-edge technology! Our diamond growth experiments have reached new heights.

4.7 / 5

Superb craftsmanship. The machine's durability is impressive even with heavy usage.

4.8 / 5

Highly efficient and user-friendly. A must-have for any serious lab.

4.9 / 5

Outstanding performance! The reactor bell-jar design is innovative and effective.

4.8 / 5

Fast shipping and excellent customer support. The machine exceeded our expectations.

4.9 / 5

Perfect for high-precision diamond growth. The build quality is unmatched.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

KINTEK MPCVD Diamond Machine: High-quality diamond synthesis with advanced MPCVD technology. Faster growth, superior purity, customizable options. Boost production now!

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

KINTEK MPCVD Systems: Grow high-quality diamond films with precision. Reliable, energy-efficient, and beginner-friendly. Expert support available.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

KINTEK's HFCVD system delivers high-quality nano-diamond coatings for wire drawing dies, enhancing durability with superior hardness and wear resistance. Explore precision solutions now!

Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

KINTEK Electric Rotary Kiln: Precise 1100℃ calcination, pyrolysis & drying. Eco-friendly, multi-zone heating, customizable for lab & industrial needs.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

CF sapphire viewing window for ultra-high vacuum systems. Durable, clear, and precise for semiconductor and aerospace applications. Explore specs now!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Laboratory Muffle Oven Furnace with Bottom Lifting

Boost lab efficiency with KT-BL Bottom Lifting Furnace: precise 1600℃ control, superior uniformity, and enhanced productivity for material science and R&D.