MPCVD

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

Item Number : MP-CVD-101

Price varies based on specs and customizations

- Output power

- 3-75kW continuously adjustable

- Sample stage diameter

- ≥200mm

- Operating frequency

- 915±15MHz

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KINTEK MPCVD Diamond Machine: Revolutionizing Diamond Synthesis

The KINTEK MPCVD Diamond Machine leverages Microwave Plasma Chemical Vapor Deposition (MPCVD) to synthesize high-quality diamonds with unprecedented speed and precision. This advanced technology enables faster crystal growth, increased production capacity, and enhanced diamond quality compared to traditional methods.

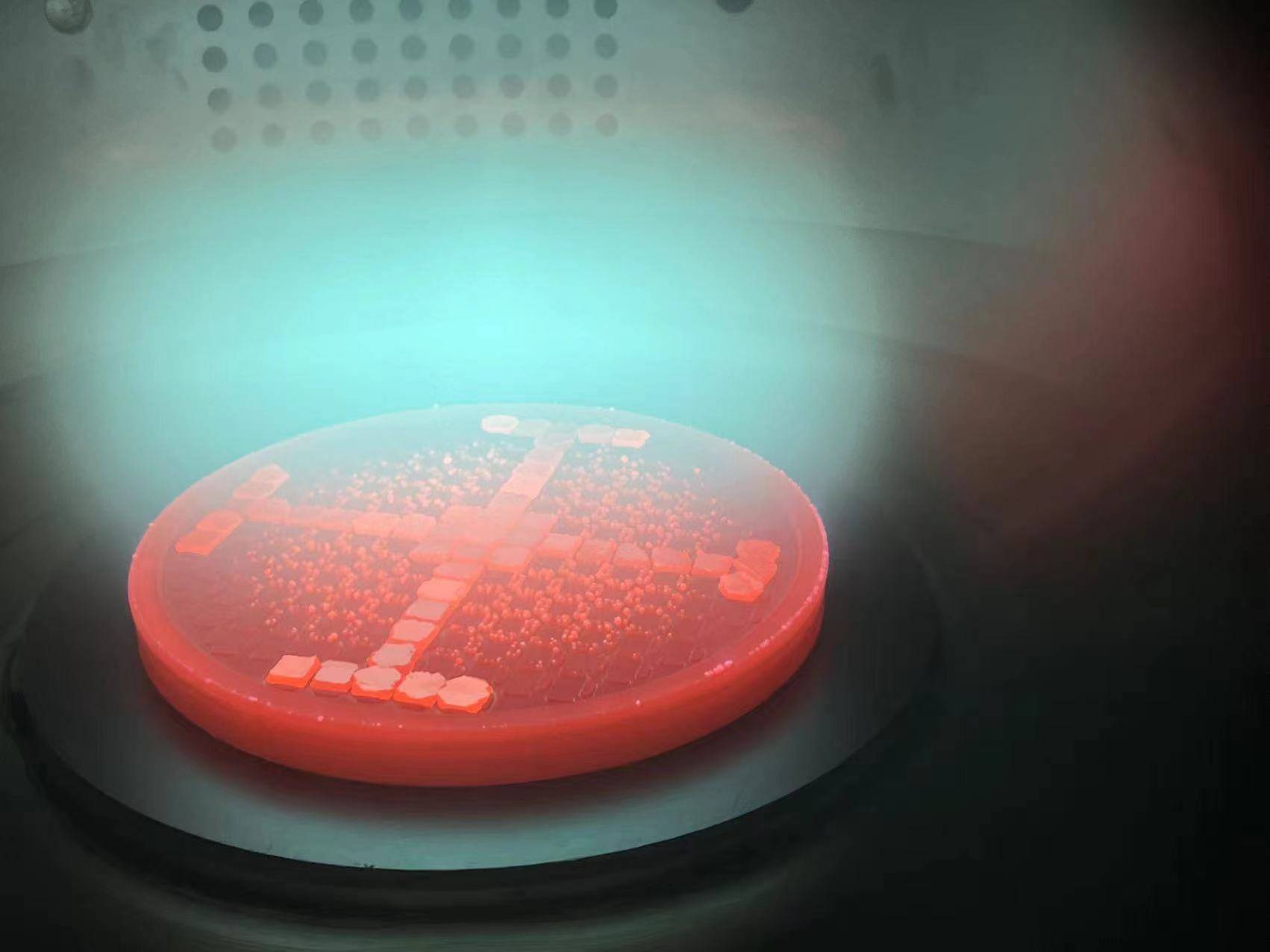

Visual Overview & Key Components

Unlock Superior Diamond Production with KINTEK

Our MPCVD Diamond Machine offers significant advantages for your diamond synthesis needs:

- Accelerated Crystal Growth: Achieve growth speeds 10-100 times faster than traditional methods, significantly boosting production efficiency.

- Increased Production Capacity: Synthesize larger batches of diamonds in a single run, maximizing your output.

- Exceptional Diamond Quality: Produce diamonds with higher hardness and toughness than natural diamonds, ensuring superior durability and performance.

- Diverse Color Options: Create diamonds in a variety of colors, including white, yellow, pink, and blue, to meet diverse market demands and aesthetic preferences.

- Unmatched Purity: Achieve higher purity levels than natural Type II diamonds, resulting in exceptional optical properties and suitability for advanced applications.

- Tailored to Your Needs: Benefit from multi-style customization. We can adapt designs to meet specific market requirements and unique experimental setups.

The Science Behind the Sparkle: Advanced MPCVD Technology

Microwave Plasma Chemical Vapor Deposition (MPCVD) is a sophisticated process where a continuous microwave source generates and sustains a highly reactive plasma. This plasma is composed of reacting chemicals (typically methane and hydrogen) and essential catalysts, which are then used to cultivate new diamond layers on a diamond-seeded substrate.

The KINTEK MPCVD Diamond Machine allows for precise control over microwave power and reaction temperature, effectively eliminating common issues faced in other CVD methods. By optimizing the reaction chamber design and process parameters, it achieves a stable plasma discharge – a crucial factor for consistently producing high-quality, large-size single-crystal diamonds.

Versatile Applications Across Industries

The unique properties of diamonds produced by our MPCVD machines – including exceptional hardness, stiffness, high thermal conductivity, low thermal expansion, radiation-hardness, and chemical inertness – make them invaluable across various sectors:

- Gemstone Industry: The primary equipment for growing high-quality, large-size diamond gemstones.

- Advanced Materials & Semiconductors: Production of diamond films for diverse applications, including large-size diamond substrates for the semiconductor industry and high-performance diamond cutting or drilling tools.

- Industrial Tools: Development of diamond coatings for cutting tools, drill bits, and other industrial applications where extreme hardness and durability are paramount.

- Biomedical Sector: Creation of biocompatible and durable diamond coatings for medical implants, such as artificial joints and dental implants.

- Optoelectronics: Manufacturing of diamond windows and substrates for high-power lasers, detectors, and other optoelectronic devices where high thermal conductivity and low thermal expansion are critical.

Technical Specifications

|

Microwave system (according to optional power supply) |

|

|---|---|

|

Vacuum system and reaction chamber |

|

|

Sample holder system |

|

|

Gas system |

|

|

System cooling |

|

|

Temperature measurement method |

|

SL901A Equipment Key Part List

| serial number | Module name | Remark |

|---|---|---|

| 1 | Microwave power supply | Standard domestic magnetron: Yingjie Electric / Distinguish power supply Domestic solid-state source: Watson (+30,000) Imported magnetron: MKS/ pastoral (+100, 000) |

| 2 | Waveguide, three pins, mode converter, upper resonator | Self made |

| 3 | Vacuum reaction chamber (upper chamber, lower chamber, connectors) | Self made |

| 4 | Infrared thermometers, optical displacement components, brackets | Infrared thermometers, optical displacement components, Fuji Gold Siemens + Schneider brackets |

| 5 | Water-cooling table motion components (cylinders, workpieces, etc.) | |

| 6 | Ceramic thin film vacuum gauge,Pirani vacuum gauge | Inficon |

| 7 | Vacuum valve components (ultra-high vacuum gate valve, precision pneumatic valve*2, electromagnetic vacuum charging differential valve) | Fujikin + Zhongke + Himat |

| 8 | Vacuum pump and connecting pipe fittings, tee, KF25 bellows*2, adapter | Pump: Flyover 16L |

| 9 | Metal microwave sealing ring*2; metal vacuum sealing ring*1; Quartz plate | Quartz: Shanghai FeilihuaSemiconductor Grade High Purity Quartz |

| 10 | Circulating water components (joints, diverter blocks, flow detectors) | Japanese SMC/CKD |

| 11 | Pneumatic part (CKD filter, airtac multi-way solenoid valve, pipe fittings and adapters) | |

| 12 | Gas connector, EP gas pipe, VCR connector, filter 0.0023μm *1, filter 10μm*2 | Fujikin |

| 13 | Machine casing, stainless steel table, universal wheels, feet, bracket fastening screws, etc | custom processing |

| 14 | Gas flow meter*6 (including one pressure control) | Standard seven-star , optional Fuji Gold ( +34,000 ) / Alicat (42,000) |

| 15 | Gas plate processing (5-way gas, filter*5, pneumatic valve*5, manual valve*6, pipeline welding) | Fuji Gold |

| 16 | PLC automatic control | Siemens + Schneider |

| 17 | Molybdenum table | |

Partner with KINTEK for Your Advanced Material Needs

Leveraging exceptional R&D and in-house manufacturing, KINTEK specializes in advanced high-temperature furnace solutions like the MPCVD Diamond Machine. We pride ourselves on our strong deep customization capability, ensuring our systems, including this advanced diamond synthesis equipment, precisely meet your unique experimental and production requirements.

Ready to elevate your diamond synthesis? KINTEK’s MPCVD Diamond Machine offers unparalleled precision and efficiency. Contact us today to discuss your specific requirements and discover how our technology can elevate your operations. Fill out the form below or click here to get started and request a quote or consultation!

FAQ

What Is The Principle Of An MPCVD Machine?

What Are The Advantages Of Using An MPCVD Machine?

What Are The Key Applications Of MPCVD Machines?

What Are The Main Components Of An MPCVD Machine?

How Does An MPCVD Machine Enhance Energy Efficiency?

Why Is MPCVD Preferred For Diamond Growth?

4.8 / 5

Incredible precision and speed! This machine delivers flawless diamond deposition every time. Worth every penny!

4.9 / 5

The quality is unmatched. Our lab's efficiency has skyrocketed since we got this reactor. Highly recommend!

4.7 / 5

Fast delivery and easy setup. The technological advancement in this system is mind-blowing. Love it!

4.8 / 5

Durability is top-notch. This machine handles continuous use without a hitch. A game-changer for our research!

4.9 / 5

The value for money is exceptional. The results are consistently high-quality. Couldn't be happier!

4.7 / 5

Superb performance! The 915MHz frequency makes all the difference. Our experiments have never been smoother.

4.8 / 5

This reactor is a beast! The diamond deposition is faster and more efficient than anything we've used before.

4.9 / 5

The build quality is outstanding. It's clear this was designed with cutting-edge technology. Impressive!

4.7 / 5

Reliable and efficient. This machine has exceeded all our expectations. A must-have for any serious lab.

4.8 / 5

The speed of delivery was impressive. The machine works flawlessly right out of the box. Perfect!

4.9 / 5

This reactor is a dream come true. The diamond quality is pristine, and the process is so streamlined. Love it!

4.7 / 5

Top-tier technology at an affordable price. This machine has revolutionized our workflow. Absolutely stellar!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

KINTEK MPCVD Systems: Grow high-quality diamond films with precision. Reliable, energy-efficient, and beginner-friendly. Expert support available.

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

KINTEK Electric Rotary Kiln: Precise 1100℃ calcination, pyrolysis & drying. Eco-friendly, multi-zone heating, customizable for lab & industrial needs.

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

2200°C Tungsten Vacuum Furnace for high-temperature materials processing. Precise control, superior vacuum, customizable solutions. Ideal for research & industrial applications.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

1200℃ Muffle Oven Furnace for Laboratory

KINTEK KT-12M Muffle Furnace: Precision 1200°C heating with PID control. Ideal for labs needing rapid, uniform heat. Explore models & customization options.

1800℃ High Temperature Muffle Oven Furnace for Laboratory

KINTEK Muffle Furnaces: Precision 1800°C heating for labs. Energy-efficient, customizable, with PID control. Ideal for sintering, annealing, and research.

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

1700℃ High Temperature Muffle Oven Furnace for Laboratory

KT-17M Muffle Furnace: High-precision 1700°C lab furnace with PID control, energy efficiency, and customizable sizes for industrial & research applications.

1400℃ Muffle Oven Furnace for Laboratory

KT-14M Muffle Furnace: Precision 1400°C heating with SiC elements, PID control, and energy-efficient design. Ideal for labs.

Related Articles

The Invisible Battle: Material Science in High-Temperature Magnesium Evaporation

Molten magnesium's extreme reactivity demands chemically inert crucibles like high-purity alumina to prevent catastrophic contamination and ensure purity.

From Dust to Discipline: Engineering Predictability in Magnesium Smelting

Discover why pelletizing isn't just shaping material, but a crucial act of engineering control for predictable high-temperature reactions.

The Hidden Tax of Molten Metal: Rethinking Magnesium Purification Economics

Vacuum sublimation slashes magnesium purification costs by eliminating the liquid phase, making expensive consumables like graphite crucibles obsolete.