CVD & PECVD Furnace

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

Item Number : KT-PE12

Price varies based on specs and customizations

- Max. temperature

- 1200℃

- RF Plasma Output Power

- 5-500W

- Rated vacuum pressure

- 10Pa~6x10-4Pa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Unlock Precision Thin Film Deposition

The KINTEK Slide PECVD Tube Furnace with Liquid Gasifier is a state-of-the-art system engineered for versatile and high-performance thin film deposition. Designed to meet the rigorous demands of modern research and production, it combines a 500W RF plasma source, an innovative slide-out furnace for rapid thermal cycling, precise gas flow control, and a robust vacuum station. Whether for electronics, semiconductors, optics, or advanced materials science, this system delivers exceptional results and reliability. At KINTEK, we leverage our exceptional R&D expertise and in-house manufacturing to provide advanced furnace solutions like this, and offer strong deep customization to precisely meet your unique experimental requirements.

Key Features & Benefits

The Slide PECVD Tube Furnace With Liquid Gasifier PECVD Machine offers numerous benefits to enhance your research and production:

- Enhanced Power Generation: The innovative graphite boat structure significantly improves the power output of solar cell wafers.

- Uniform Cell Quality: Effectively eliminates color differences in tubular PECVD cells, ensuring consistent results.

- Versatile RF Plasma Source: Features an automatic matching RF plasma source with a wide output power range (5-500W) for stable and adaptable performance across various applications.

- Rapid Thermal Cycling: The furnace chamber sliding system enables high-speed heating and cooling, significantly reducing processing time. Auxiliary forced air circulation further accelerates the cooling rate.

- Automated Operation: Optional automated sliding movement enhances efficiency and reduces manual intervention for streamlined workflows.

- Precise Temperature Management: PID programmable temperature control ensures accurate temperature regulation. Supports remote and centralized control for added convenience and operational flexibility.

- Accurate Gas Control: High-accuracy MFC mass flowmeters precisely control source gases, ensuring a stable, consistent, and premixed gas supply.

- High-Performance Vacuum System: The stainless steel vacuum flange with multiple adapting ports accommodates various vacuum pump station configurations, ensuring a high vacuum degree and reliable sealing.

- User-Friendly Interface: Equipped with the CTF Pro 7-inch TFT touch screen controller, simplifying program setting, operation, and allowing for easy analysis of historical data.

Versatile Applications

The Slide PECVD Tube Furnace With Liquid Gasifier PECVD Machine is ideal for a wide range of applications, including:

- Chemical Vapor Deposition (CVD)

- Plasma Enhanced Chemical Vapor Deposition (PECVD)

- Thin film deposition for various materials

- Solar cell fabrication and research

- Semiconductor processing

- Nanotechnology research and development

- Advanced materials science studies

- General research and development in controlled atmospheres

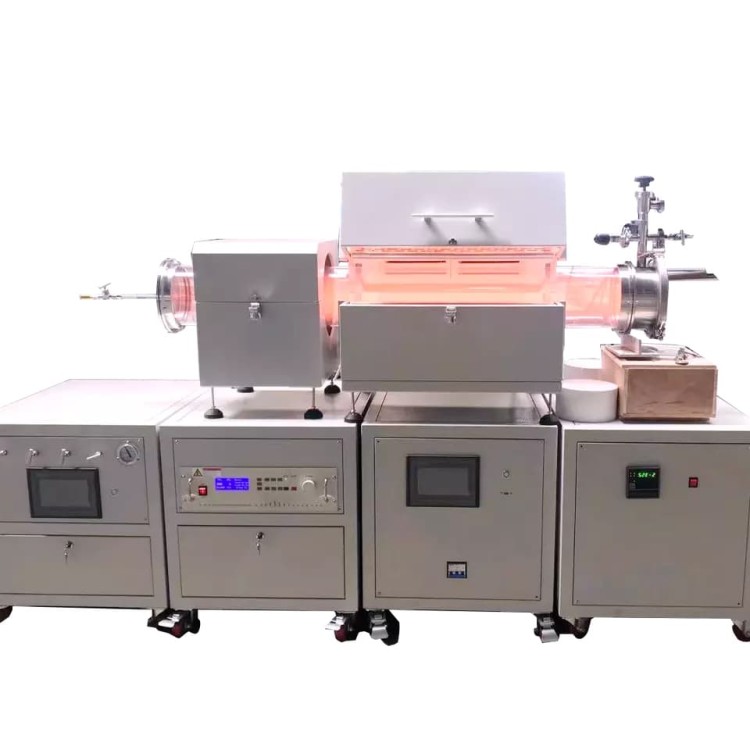

Explore Our System Configurations

KINTEK offers various CVD system setups to meet diverse experimental needs. Below are examples of available configurations:

Operating Principle

The Slide PECVD Tube Furnace With Liquid Gasifier PECVD Machine employs low-temperature plasma to generate a glow discharge in the process chamber's cathode (sample tray). The glow discharge (or another heat source) raises the sample's temperature to a predetermined level. Then, controlled amounts of process gas are introduced, undergoing chemical and plasma reactions to form a solid film on the sample's surface.

Built-in Safety Advantages

- Over-Current and Over-Temperature Protection: The furnace is equipped with over-current protection and over-temperature alarming functions, automatically shutting off power if limits are exceeded.

- Thermocouple Failure Detection: A built-in thermocouple detecting function will stop heating and trigger an alarm if a broken or failed thermocouple is detected, preventing uncontrolled heating.

- Power Failure Restart Function: The PE Pro controller supports a power failure restarting function, allowing the furnace to resume its heating program automatically once power is restored after an outage.

Technical Specifications

| Furnace model | KT-PE12-60 |

| Max. temperature | 1200℃ |

| Constant work temperature | 1100℃ |

| Furnace tube material | High purity quartz |

| Furnace tube diameter | 60mm |

| Heating zone length | 1x450mm |

| Chamber material | Japan alumina fiber |

| Heating element | Cr2Al2Mo2 wire coil |

| Heating rate | 0-20℃/min |

| Thermal couple | Build in K type |

| Temperature controller | Digital PID controller/Touch screen PID controller |

| Temperature control accuracy | ±1℃ |

| Sliding distance | 600mm |

| RF Plasma unit | |

| Output Power | 5 -500W adjustable with ± 1% stability |

| RF frequency | 13.56 MHz ±0.005% stability |

| Reflection Power | 350W max. |

| Matching | Automatic |

| Noise | |

| Cooling | Air cooling. |

| Gas precise control unit | |

| Flow meter | MFC mass flow meter |

| Gas channels | 4 channels |

| Flow rate | MFC1: 0-5SCCM O2 MFC2: 0-20SCMCH4 MFC3: 0- 100SCCM H2 MFC4: 0-500 SCCM N2 |

| Linearity | ±0.5% F.S. |

| Repeatability | ±0.2% F.S. |

| Pipe line and valve | Stainless steel |

| Maximum Operating Pressure | 0.45MPa |

| Flow meter controller | Digital Knob controller/Touch screen controller |

| Standard vacuum unit(Optional) | |

| Vacuum pump | Rotary vane vacuum pump |

| Pump flow rate | 4L/S |

| Vacuum suction port | KF25 |

| Vacuum gauge | Pirani/Resistance silicon vacuum gauge |

| Rated vacuum pressure | 10Pa |

| High vacuum unit(Optional) | |

| Vacuum pump | Rotary vane pump+Molecular pump |

| Pump flow rate | 4L/S+110L/S |

| Vacuum suction port | KF25 |

| Vacuum gauge | Compound vacuum gauge |

| Rated vacuum pressure | 6x10-4Pa |

| Above specifications and setups can be customized | |

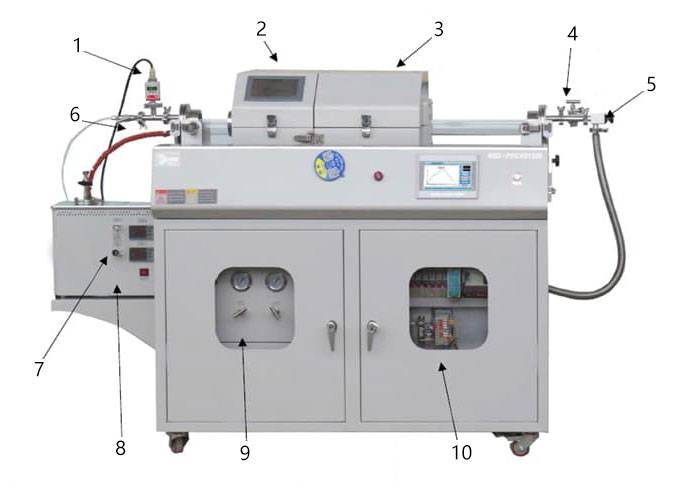

Standard Package Contents

| No. | Description | Quantity |

| 1 | Furnace | 1 |

| 2 | Quartz tube | 1 |

| 3 | Vacuum flange | 2 |

| 4 | Tube thermal block | 2 |

| 5 | Tube thermal block hook | 1 |

| 6 | Heat resistant glove | 1 |

| 7 | RF plasma source | 1 |

| 8 | Precise gas control | 1 |

| 9 | Vacuum unit | 1 |

| 10 | Operation manual | 1 |

Customization & Optional Setups

At KINTEK, we pride ourselves on our strong deep customization capability. We can tailor the Slide PECVD Tube Furnace to precisely meet your unique experimental requirements. Available optional setups include:

- In-tube gas detection and monitoring (e.g., H2, O2)

- Independent furnace temperature monitoring and recording systems

- RS 485 communication port for PC remote control and data exporting

- Customized gas feeding flow rate control (mass flowmeters or float flowmeters)

- Advanced touch screen temperature controller with versatile, operator-friendly functions

- Various high vacuum pump station setups (e.g., vane vacuum pump, molecular pump, diffusion pump)

Partner with KINTEK for Your Advanced Furnace Needs

KINTEK's Slide PECVD Tube Furnace is designed for adaptability and high performance. We understand that your research is unique. Leverage our strong deep customization capabilities to tailor this system to your exact specifications. Whether you need different temperature ranges, specific gas configurations, advanced control features, or unique vacuum setups, our expert team is ready to assist.

Ready to elevate your research or production? Discuss your requirements with our experts and get a personalized quote. Please fill out our contact form, and one of our specialists will be in touch shortly to help you configure the perfect PECVD solution!

FAQ

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Is The Principle Of A CVD Machine?

What Are The Common Applications Of A Split Tube Furnace?

What Is A Vertical Tube Furnace?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Advantages Of Using A CVD Machine?

What Are The Key Features Of A Split Tube Furnace?

What Are The Applications Of A Vertical Tube Furnace?

What Are The Advantages Of Using A Tube Furnace?

How Does A Multi-zone Tube Furnace Work?

What Are The Applications Of A CVD Machine?

How Does A Split Tube Furnace Work?

What Are The Advantages Of A Vertical Tube Furnace?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Are The Key Features Of A CVD Machine?

What Are The Advantages Of Using A Split Tube Furnace?

How Does A Vertical Tube Furnace Work?

What Temperature Ranges Can Tube Furnaces Achieve?

What Types Of Multi-zone Tube Furnaces Are Available?

What Types Of CVD Machines Are Available?

What Temperature Can A Split Tube Furnace Reach?

What Types Of Vertical Tube Furnaces Are Available?

Can Tube Furnaces Operate Under Different Atmospheres?

Why Is The Split Design Beneficial In A Tube Furnace?

Why Choose A Vertical Tube Furnace Over A Horizontal One?

What Makes KINTEK Tube Furnaces Special?

What Temperature Ranges Can Vertical Tube Furnaces Achieve?

Are Vertical Tube Furnaces Customizable?

4.9 / 5

Incredible precision and efficiency! This machine has revolutionized our lab workflow.

4.8 / 5

Fast delivery and top-notch quality. Worth every penny for advanced research.

4.7 / 5

The durability is unmatched. A reliable workhorse for high-temperature applications.

4.9 / 5

Cutting-edge technology with seamless integration. Highly recommended for serious labs.

4.8 / 5

Exceptional value for money. The liquid gasifier feature is a game-changer.

4.9 / 5

Superior build quality and performance. Exceeded all our expectations.

4.7 / 5

Easy to operate and maintain. Perfect for both beginners and experts.

4.8 / 5

Fast setup and outstanding results. A must-have for any advanced lab.

4.9 / 5

The technological advancement is mind-blowing. Delivered ahead of schedule!

4.8 / 5

Robust and reliable. Perfect for continuous high-performance tasks.

4.9 / 5

Precision engineering at its finest. Our experiments have never been smoother.

4.7 / 5

Great investment for any lab. The quality speaks for itself.

4.8 / 5

Innovative design and flawless performance. A standout in its category.

4.9 / 5

The speed and accuracy are unparalleled. A true technological marvel.

4.7 / 5

User-friendly and highly efficient. Perfect for complex applications.

4.8 / 5

Outstanding durability and performance. Delivered faster than expected.

4.9 / 5

A masterpiece of engineering. The liquid gasifier is a brilliant addition.

4.7 / 5

Consistent results every time. A reliable partner for advanced research.

4.8 / 5

Exceptional build and innovative features. A top-tier machine for any lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

Precision rotary tube furnace for continuous vacuum processing. Ideal for calcination, sintering, and heat treatment. Customizable up to 1600℃.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision high-temperature processing up to 2000°C for labs. Ideal for material synthesis, CVD, and sintering. Customizable options available.

Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

KINTEK's Rotary Biomass Pyrolysis Furnace converts biomass to biochar, bio-oil, and syngas efficiently. Customizable for research or production. Get your solution now!

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

KINTEK's 304/316 stainless steel vacuum ball valves and stop valves ensure high-performance sealing for industrial and scientific applications. Explore durable, corrosion-resistant solutions.

Vacuum Hot Press Furnace Machine Heated Vacuum Press

KINTEK Vacuum Hot Pressing Furnace: Precision heating & pressing for superior material density. Customizable up to 2800°C, ideal for metals, ceramics, and composites. Explore advanced features now!

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!