MPCVD

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

Item Number : KTWB315

Price varies based on specs and customizations

- Microwave output power

- 1~10 KW continuously adjustable

- Substrate growing area

- 3 inches

- Maximum batch load

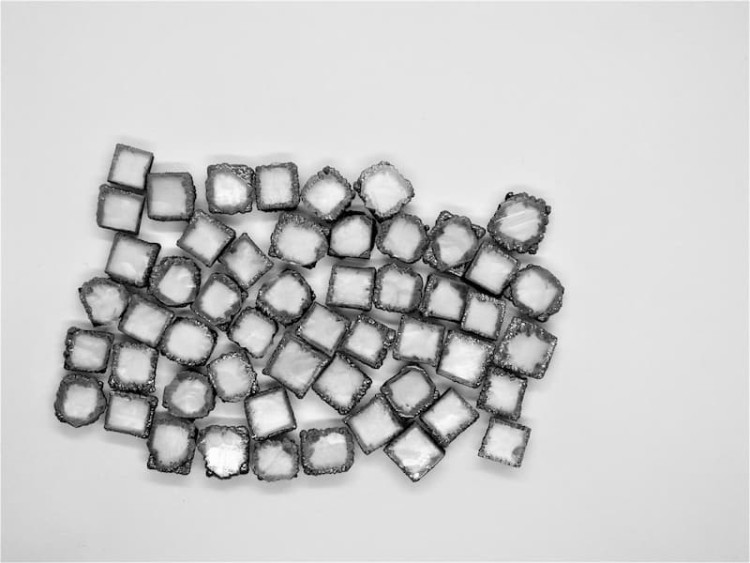

- 45 pieces of diamonds

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including our cutting-edge MPCVD Systems. Our product line, encompassing Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and various CVD/PECVD/MPCVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

KINTEK MPCVD Systems: Grow High-Quality Diamond Films with Precision

Our Microwave Plasma Chemical Vapor Deposition (MPCVD) systems are engineered for laboratories and industries aiming to grow superior quality diamond films. By utilizing a carbon-containing gas and a microwave plasma, KINTEK's MPCVD technology offers a reliable and efficient method for diamond synthesis.

Why Choose KINTEK's MPCVD System?

With years of deep industry involvement and a vast customer base, KINTEK's MPCVD equipment is trusted for its performance and reliability. Our systems have demonstrated:

- Exceptional Stability & Reliability: Proven with over 40,000 hours of steady operation.

- Repeatability & Cost-Effectiveness: Consistently deliver high-quality results efficiently.

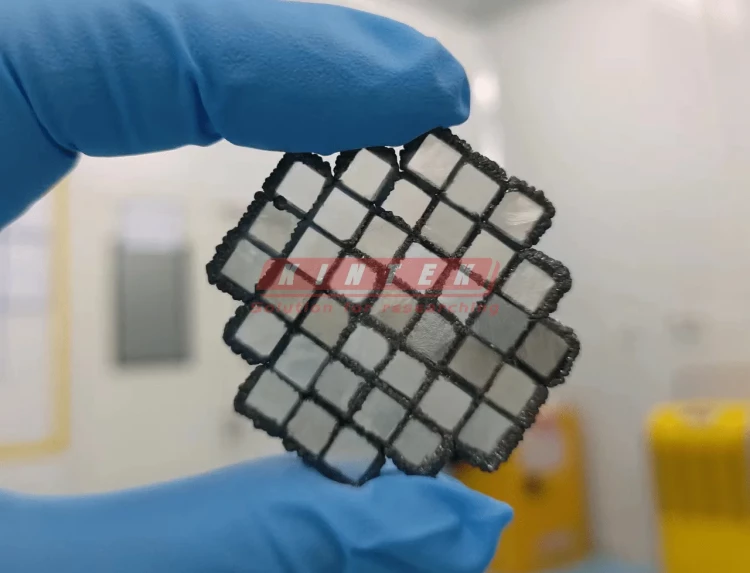

- High Capacity: 3 inches substrate growing area, with a maximum batch load of up to 45 pieces of diamonds.

- Energy Efficient: 1-10KW adjustable output microwave power for reduced electricity consumption.

- Expert Support: Backed by a richly experienced research team offering frontier diamond growing recipe support.

- Beginner-Friendly: Exclusive technical support program for teams with zero diamond growing experience.

By leveraging our accumulated advanced technology, we have implemented multiple rounds of upgrades and improvements to our MPCVD system, resulting in significantly improved efficiency and reduced equipment costs. As a result, our MPCVD equipment is at the forefront of technological advancements and offered at a competitive price. Ready to advance your diamond growth capabilities? Consult with our experts today!

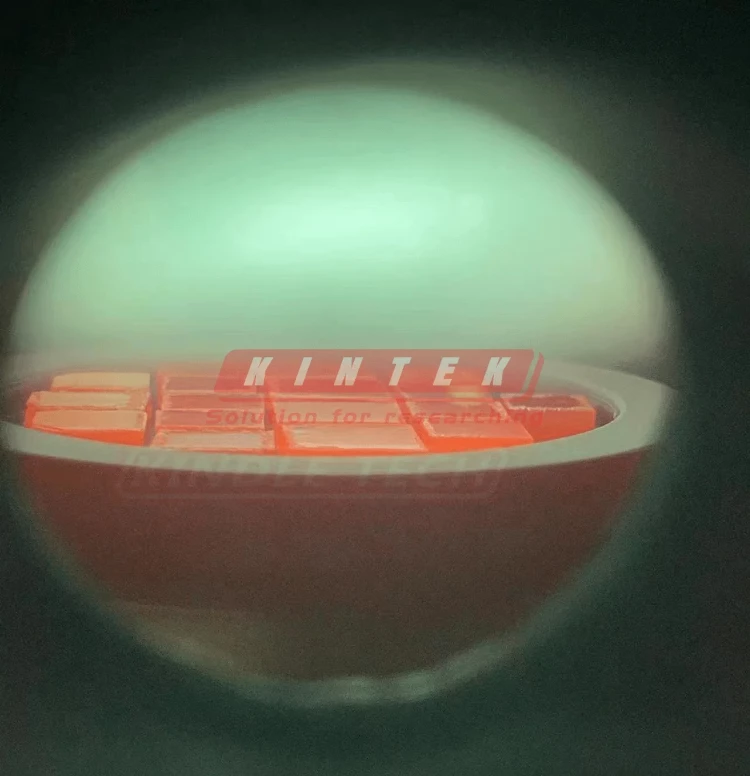

Visual Showcase: Results with KINTEK MPCVD

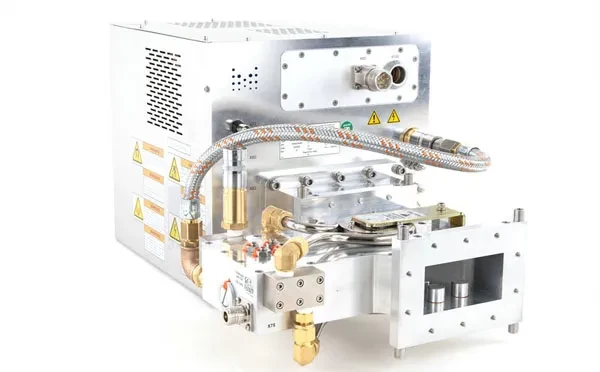

Key Features & System Components

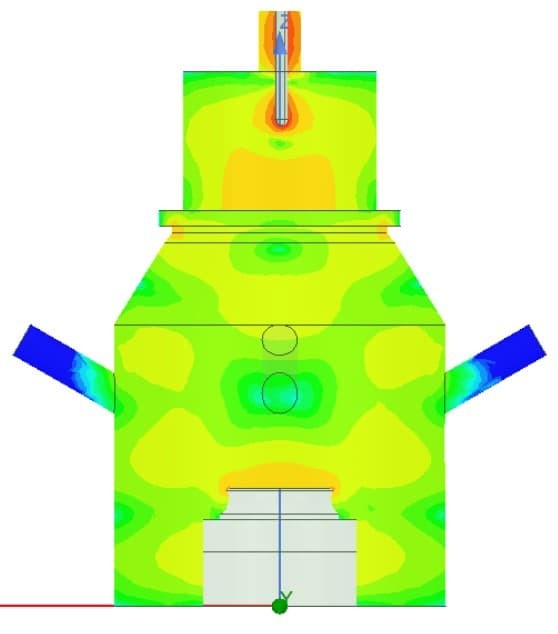

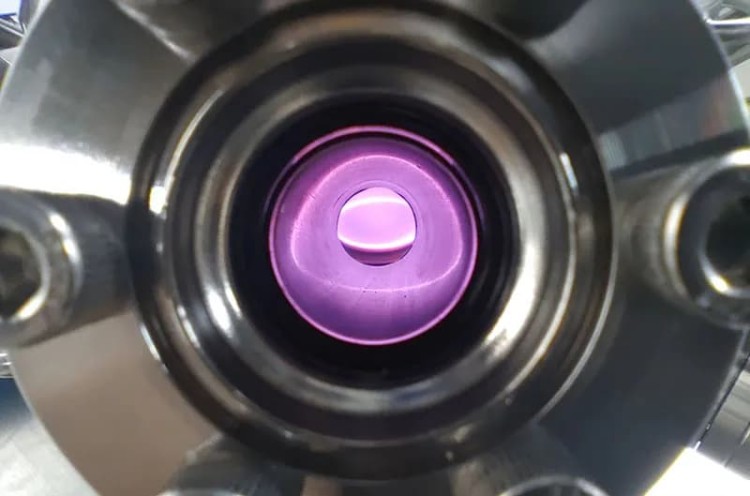

Our MPCVD systems are designed with precision components for optimal performance during the deposition process. The system typically consists of a vacuum chamber, a microwave generator (often a magnetron or klystron operating around 2.45 GHz coupled via a quartz window), a precise gas delivery system with mass flow controllers (MFCs), and temperature control mechanisms.

Microwave system

Reaction chamber

Gas flow system

Vacuum and sensor system

Technical Specifications

| Microwave system |

|

| Reaction chamber |

|

| Sample holder |

|

| Gas flow system |

|

| Cooling system |

|

| Temperature sensor |

|

| Control system |

|

| Optional function |

|

The KINTEK MPCVD Advantage: Superior Diamond Synthesis

KINTEK's MPCVD technology offers significant advantages for diamond synthesis compared to other methods like HFCVD (Hot Filament CVD) and DC-PJ CVD (Direct Current Plasma Jet CVD):

- High Purity Diamonds: MPCVD avoids diamond contamination from elements like hot wires (as in HFCVD). In our system, the plasma ball doesn't contact the cavity wall, ensuring an impurity-free growth process and leading to diamonds of higher purity compared to those from the HPHT (High-Pressure High-Temperature) method.

- Versatile Gas Use: Allows the use of multiple gases (e.g., CH4, H2, Ar, O2, N2) to meet diverse industrial needs and tailor diamond properties.

- Stable & Precise Control: Enables smooth, continuous adjustment of microwave power and stable control of reaction temperature. This avoids issues like crystal seeds falling off the substrate due to arcing and flame failure sometimes seen in DC-PJ CVD. The substrate temperature is precisely controlled by the plasma position and measured by a thermocouple.

- Large Area Stable Plasma: The MPCVD method generates a large area of stable discharge plasma, making it the most promising diamond synthesis method for industrial applications and scaling up production.

- Energy Efficient & Cost-Effective for Larger Diamonds: The MPCVD production process typically consumes less energy than HPHT and facilitates the production of larger, high-quality diamonds at a potentially lower cost.

Looking for a reliable and advanced diamond synthesis solution that delivers purity and performance? Request a quote for our MPCVD system!

Working Principle: How KINTEK MPCVD Grows Diamonds

The KINTEK MPCVD machine meticulously controls the growth environment. The process begins by controlling the flow of each gas path (reactant gases such as CH4, H2, Ar, O2, N2, etc.) and cavity pressure, introducing these gases into the cavity under specific, stabilized conditions. Once airflow is stable, the 6KW (or adjustable 1-10KW) solid-state microwave generator generates microwaves, which are then introduced into the cavity through a waveguide.

Under the microwave field, the reaction gas transforms into a plasma state, forming a plasma ball that hovers above the diamond substrate. The high temperature of the plasma heats the substrate to the specific temperature required for diamond growth. Excess heat produced in the cavity is efficiently dissipated by the water cooling unit.

To ensure optimal growth conditions during the MPCVD single crystal diamond growth process, factors such as microwave power, gas source composition, and cavity pressure are precisely adjusted. The non-contact nature of the plasma ball with the cavity wall is crucial, as it prevents impurities from contaminating the diamond growth process, thereby enhancing the final quality of the diamond.

Applications of Diamonds Grown with KINTEK MPCVD

Diamond's unique properties—including its extreme hardness, stiffness, high thermal conductivity, low thermal expansion, radiation-hardness, and chemical inertness—make it a highly valuable material. While natural and HPHT diamonds have faced limitations due to cost, size, and impurity control, KINTEK's MPCVD technology opens doors for broader applications:

- Gemstone Quality Diamonds: MPCVD is a primary equipment used for growing diamond gemstones, offering a promising route to producing low-cost, high-quality large diamonds for the expanding jewelry market.

- Semiconductor Industry: Diamond film growth can be either monocrystal or polycrystalline. It is extensively used for large-size diamond substrates in the semiconductor industry.

- Cutting & Drilling Tools: The exceptional hardness of MPCVD diamonds makes them ideal for the diamond cutting or drilling tools industry.

- Optics and Advanced Materials: For applications leveraging diamond's unique optical and thermal properties.

Compared to the HPHT method for lab-grown diamonds, the microwave CVD method, as employed by KINTEK, is advantageous for large-sized diamond growth at a lower cost. This makes it an ideal solution for applications in semiconductor diamonds, optics diamond growth, and meeting the needs of the large jewelry diamond market.

Partner with KINTEK for Customized High-Temperature Solutions

Beyond our specialized MPCVD systems, KINTEK offers a diverse product line including Muffle Furnaces, Tube Furnaces, Rotary Furnaces, other Vacuum & Atmosphere Furnaces, and various CVD/PECVD Systems. Our core strength lies in our exceptional R&D, dedicated in-house manufacturing, and profound deep customization capabilities, allowing us to tailor solutions precisely to your specific experimental or production requirements.

Do you have unique requirements or a challenging project? We specialize in developing custom solutions. Contact KINTEK today to discuss your needs and explore how our advanced furnace technology can benefit your work!

Trusted by Industry Leaders

FAQ

What Is The Principle Of A CVD Machine?

What Is The Principle Of An MPCVD Machine?

What Is A PECVD Machine Used For?

What Are The Advantages Of Using A CVD Machine?

What Are The Advantages Of Using An MPCVD Machine?

What Are The Main Types Of PECVD Machines?

What Are The Applications Of A CVD Machine?

What Are The Key Applications Of MPCVD Machines?

How Does A PECVD Machine Work?

What Are The Key Features Of A CVD Machine?

What Are The Main Components Of An MPCVD Machine?

What Are The Key Features Of A PECVD Machine?

What Types Of CVD Machines Are Available?

How Does An MPCVD Machine Enhance Energy Efficiency?

What Are The Advantages Of Using A PECVD Machine?

Why Is MPCVD Preferred For Diamond Growth?

What Materials Can Be Deposited Using A PECVD Machine?

Why Is PECVD Preferred Over Other Deposition Methods?

4.9 / 5

This machine is a game-changer! The diamond growth speed is phenomenal, and the quality is unmatched.

4.8 / 5

Incredible value for money. The precision and durability of this system are top-notch.

4.7 / 5

Fast delivery and easy setup. The technological advancement in this machine is mind-blowing.

4.9 / 5

The consistency in diamond quality is impressive. Worth every penny!

4.8 / 5

Highly efficient and reliable. Perfect for lab diamond growth with minimal maintenance.

4.7 / 5

The cylindrical resonator design is brilliant. Delivers flawless diamonds every time.

4.9 / 5

Exceptional performance! The machine’s durability and advanced tech make it a must-have.

4.8 / 5

Superb investment. The speed and quality of diamond growth exceed expectations.

4.7 / 5

Love the precision! This machine has revolutionized our lab’s diamond production.

4.9 / 5

Outstanding build quality. The diamonds produced are of impeccable clarity and size.

4.8 / 5

Fast, efficient, and reliable. The best MPCVD system we’ve used so far.

4.7 / 5

The technology behind this machine is cutting-edge. Highly recommend for any lab.

4.9 / 5

Perfect for high-volume diamond growth. The quality is consistently excellent.

4.8 / 5

A stellar purchase! The machine’s performance and durability are unmatched.

4.7 / 5

Incredibly advanced and user-friendly. Delivers perfect diamonds with ease.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

KINTEK MPCVD Systems: Precision diamond growth machines for high-purity lab-grown diamonds. Reliable, efficient, and customizable for research and industry.

915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

KINTEK MPCVD Diamond Machine: High-quality diamond synthesis with advanced MPCVD technology. Faster growth, superior purity, customizable options. Boost production now!

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

Advanced PECVD Tube Furnace for precise thin film deposition. Uniform heating, RF plasma source, customizable gas control. Ideal for semiconductor research.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Vacuum Hot Press Furnace Machine for Lamination and Heating

KINTEK Vacuum Lamination Press: Precision bonding for wafer, thin-film & LCP applications. 500°C max temp, 20-ton pressure, CE certified. Custom solutions available.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Spark Plasma Sintering SPS Furnace

Discover KINTEK's advanced Spark Plasma Sintering (SPS) Furnace for rapid, precise material processing. Customizable solutions for research and production.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

Achieve superior ceramic densification with KINTEK's advanced air pressure sintering furnace. High-pressure up to 9MPa, precise 2200℃ control.