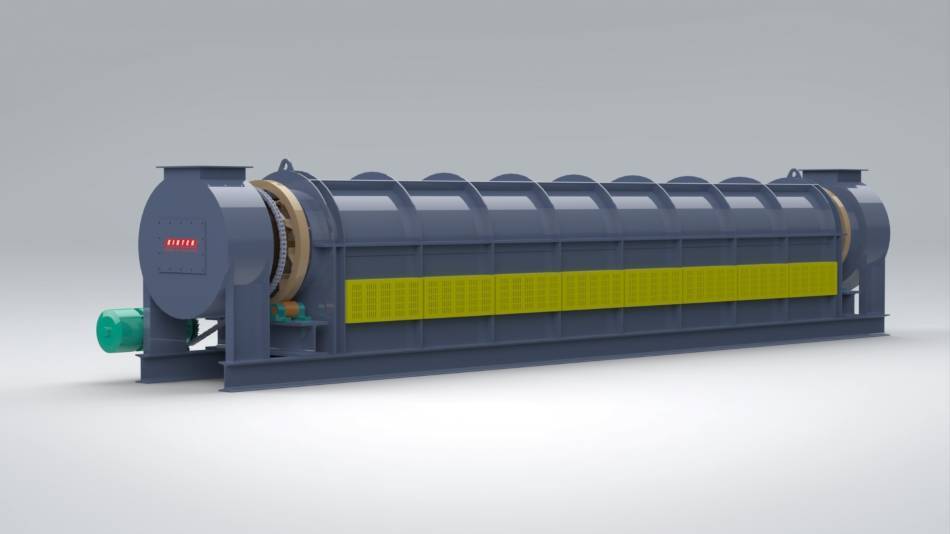

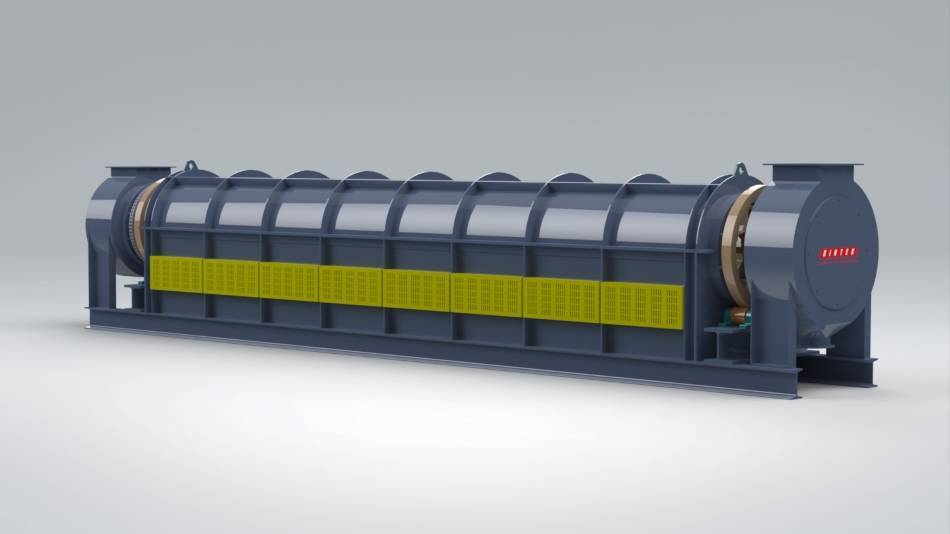

Electric Rotary Kiln

Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

Item Number : KT-RKTF

Price varies based on specs and customizations

- Work temperature

- < 1100℃

- Tube diameter

- 0.6~1.2m

- Tube length

- 7~12m

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KINTEK Electric Rotary Kiln / Calciner / Pyrolysis Furnace

KINTEK's Electric Rotary Kiln (also referred to as Electric Rotary Calciner or Pyrolysis Furnace) is an advanced external heating system engineered for high-temperature material processing. Utilizing clean electricity as its heating source, this furnace offers precise temperature control up to 1100℃ and is ideal for a wide range of applications including calcination, drying, pyrolysis, and other critical thermal treatments. Built with robust KINTEK R&D and in-house manufacturing, it's a versatile solution for diverse industrial and laboratory needs.

Key Features and Benefits

- Clean and Efficient Electric Heating: Utilizes electricity for an environmentally friendly process, reducing smoke, ash, and slag, leading to high thermal efficiency. Eliminates the need for fuel storage and transportation.

- Precise Temperature Control: Features an intelligent PID thermal controller with a touch screen PLC, ensuring accurate temperature management up to 1100℃. This precision is crucial for processes requiring narrow pre-firing temperature ranges and ensures consistent, high-quality results. Includes over-temperature and sensor break alarms for operational safety.

- Multi-Zone Heating: Designed with up to 4 independent heating zones, allowing for tailored temperature profiles along the length of the rotary tube to meet specific processing requirements.

- Durable High-Temperature Construction: The rotary tube is fabricated from nickel-based alloys, capable of withstanding working temperatures up to 1100℃ without deformation and offering excellent corrosion resistance.

- Superior Heating Elements: Equipped with high-quality Silicon Carbide (SiC) heating elements known for their extended service life, stable performance, and ease of maintenance.

- Robust Insulation: Utilizes polycrystalline ceramic fiber insulation for superior thermal efficiency, minimizing heat loss and reducing energy consumption.

- Variable Speed & Tilt Control:

- The rotation speed of the drum is controlled by a variable speed electric motor, allowing for precise adjustment to optimize material residence time and processing.

- The horizontal drum can be tilted (0-3 degrees) using a hydraulic system, facilitating controlled material movement and effortless discharging.

- Controlled Atmosphere Capability: Incorporates excellent dynamic sealing technology (e.g., contact graphite block sealing) to prevent material oxidation, enabling operation under controlled inert gas protective environments.

- Advanced Operational Features:

- Supports easy automation for streamlined operations.

- The touch screen controller allows for saving multiple heating programs, easy switching between them, and provides capabilities for historical heating data analysis and research.

- Incorporates advanced technological innovations such as a hydraulic block wheel device and high-precision metering piston pump (depending on configuration) for stable performance.

- Cost-Effectiveness & Reduced Environmental Impact: Offers an economical alternative to gas or oil fuel rotary kilns, with reduced corrosion issues and environmental pollution.

Technical Specifications

| Model | KT-RKTF60 | KT-RKTF80 | KT-RKTF100 | KT-RKTF120 |

|---|---|---|---|---|

| Tube diameter | 0.6m | 0.8m | 1m | 1.2m |

| Tube length | 7m | 9m | 10m | 12m |

| Tube material | Nickel based alloy | |||

| Heating zones | 4 independent hot zones (customizable) | |||

| Work temperature | ||||

| Rotary drum angle | 0-3 degree (adjustable) | |||

| Insulation material | Polycrystalline ceramic fiber | |||

| Temperature controller | Touch screen PID controller with PLC | |||

| Heating element | Silicon Carbide (SiC) | |||

| Temperature sensor | Armed K type thermocouple | |||

| Electric power supply | AC220-440V, 50/60HZ (customizable) | |||

Note: Specifications can be customized to meet specific application requirements. Contact us for details.

Applications

KINTEK's Electric Rotary Kilns are widely used across various industries for diverse thermal treatment processes, including but not limited to:

- Calcination and drying of positive and negative electrode materials for batteries

- Processing of rare earth materials

- Production and regeneration of chemical catalytic materials

- Manufacturing of magnetic materials

- Sintering and heat treatment of powder metallurgy materials

- Processing of nonferrous metal materials

- Calcination of kaolin and other non-metallic mineral materials

- High-temperature chemical reactions

- General heat treatment processes

- Material carbonization and pyrolysis

Principle of Operation

The KINTEK Electric Rotary Kiln operates by continuously feeding material into a rotating cylindrical chamber (tube). This tube is externally heated by high-performance electric heating elements, segmented into multiple zones for precise temperature profiling. As the material tumbles and transits through the heated chamber, it undergoes the desired thermal process, such as calcination, drying, or pyrolysis. The rotation and tilt of the tube ensure uniform heating and controlled movement of the material towards the discharge end. The system can be operated under ambient or controlled atmospheres (e.g., inert gas) to prevent oxidation or achieve specific reaction conditions.

Why Choose KINTEK? Customization and Support

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industrial clients with advanced high-temperature furnace solutions. Our comprehensive product line, including Muffle Furnaces, Tube Furnaces, other Rotary Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD/MPCVD Systems, is a testament to our expertise.

We pride ourselves on our strong deep customization capability. Our team works closely with you to understand your unique experimental or production requirements and can tailor the Electric Rotary Kiln – including drum diameter, length, number of heating zones, and control systems – to precisely match your needs.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your specific application, request a detailed quote, or explore custom solutions for our Electric Rotary Kiln. Our experts are here to help you find the perfect high-temperature solution.

For detailed specifications or to learn more about how this furnace can be tailored to your application, please get in touch with our specialists.

Trusted by Industry Leaders

FAQ

What Are The Main Applications Of Electric Rotary Kilns?

What Is The Principle Of A Rotary Furnace?

What Is A Rotating Furnace Used For?

What Are The Main Applications Of A Rotary Tube Furnace?

What Are The Key Features Of Electric Rotary Kilns?

What Are The Advantages Of Using A Rotary Furnace?

What Are The Main Types Of Rotating Furnaces Available?

What Are The Key Features Of A Rotary Tube Furnace?

How Does An Electric Rotary Kiln Work?

What Are The Key Features Of A Rotary Furnace?

How Does A Rotating Furnace Work?

How Does A Rotary Tube Furnace Work?

What Are The Advantages Of Using An Electric Rotary Kiln?

What Are The Common Applications Of A Rotary Furnace?

What Are The Advantages Of Using A Rotating Furnace?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Industries Benefit From Electric Rotary Kilns?

How Does A Rotary Furnace Handle Different Materials?

What Safety Features Are Included In Rotating Furnaces?

What Temperature Can A Rotary Tube Furnace Reach?

What Temperature Range Can Electric Rotary Kilns Achieve?

Can Rotating Furnaces Be Customized For Specific Applications?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

How Does The Design Of An Electric Rotary Kiln Ensure Efficient Processing?

What Makes Electric Rotary Kilns More Energy-efficient Than Traditional Combustion Methods?

Can Electric Rotary Kilns Be Customized For Specific Applications?

How Do Electric Rotary Kilns Contribute To Environmental Sustainability?

4.8 / 5

This machine is a game-changer! Super efficient and worth every penny. Highly recommend!

4.9 / 5

Incredible quality and durability. It arrived faster than expected. Perfect for our needs!

4.7 / 5

The technology is top-notch. Easy to use and delivers consistent results. Love it!

4.9 / 5

Best investment we've made. The performance is outstanding and it's built to last.

4.8 / 5

Fast delivery and excellent customer service. The machine works flawlessly. Very impressed!

4.7 / 5

Great value for money. The rotary kiln is robust and performs beyond expectations.

4.9 / 5

Cutting-edge technology with a compact design. Perfect for small-scale operations. Highly efficient!

4.8 / 5

Reliable and powerful. The build quality is exceptional. Delivered right on time.

4.9 / 5

Absolutely love this machine! It's revolutionized our production process. Worth every cent.

4.7 / 5

Durable and efficient. The rotary kiln is a beast! Super happy with the purchase.

4.8 / 5

Fantastic product! The technology is advanced and it's incredibly easy to operate. Highly recommend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

KINTEK's electric rotary furnaces offer precision heating up to 1100°C for calcination, drying, and pyrolysis. Durable, efficient, and customizable for labs and production. Explore models now!

Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

Electric Activated Carbon Regeneration Furnace by KINTEK: High-efficiency, automated rotary kiln for sustainable carbon recovery. Minimize waste, maximize savings. Get a quote!

Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

KINTEK's Rotary Biomass Pyrolysis Furnace converts biomass to biochar, bio-oil, and syngas efficiently. Customizable for research or production. Get your solution now!

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

High-performance SiC heating elements for labs, offering 600-1600°C precision, energy efficiency, and long lifespan. Customizable solutions available.

High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

KT-MD Debinding & Pre-Sintering Furnace for ceramics - precise temperature control, energy-efficient design, customizable sizes. Boost your lab efficiency today!

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

Vacuum Induction Melting Furnace

Explore KINTEK's Vacuum Induction Melting Furnace for high-purity metal processing up to 2000℃. Customizable solutions for aerospace, alloys, and more. Contact us today!

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

KINTEK High Pressure Tube Furnace: Precision heating up to 1100°C with 15Mpa pressure control. Ideal for sintering, crystal growth, and lab research. Customizable solutions available.

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

Premium KF/ISO stainless steel vacuum blind plates for high-vacuum systems. Durable 304/316 SS, Viton/EPDM seals. KF & ISO connections. Get expert advice now!