Vacuum Accessories

Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

Item Number : KT-VA02

Price varies based on specs and customizations

- Clear View Diameter (ΦD)

- 14~146mm

- Glass Thickness (B)

- 14~24.5mm

- Temperature Range

- -200°C to +300°C

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Detail & Parts

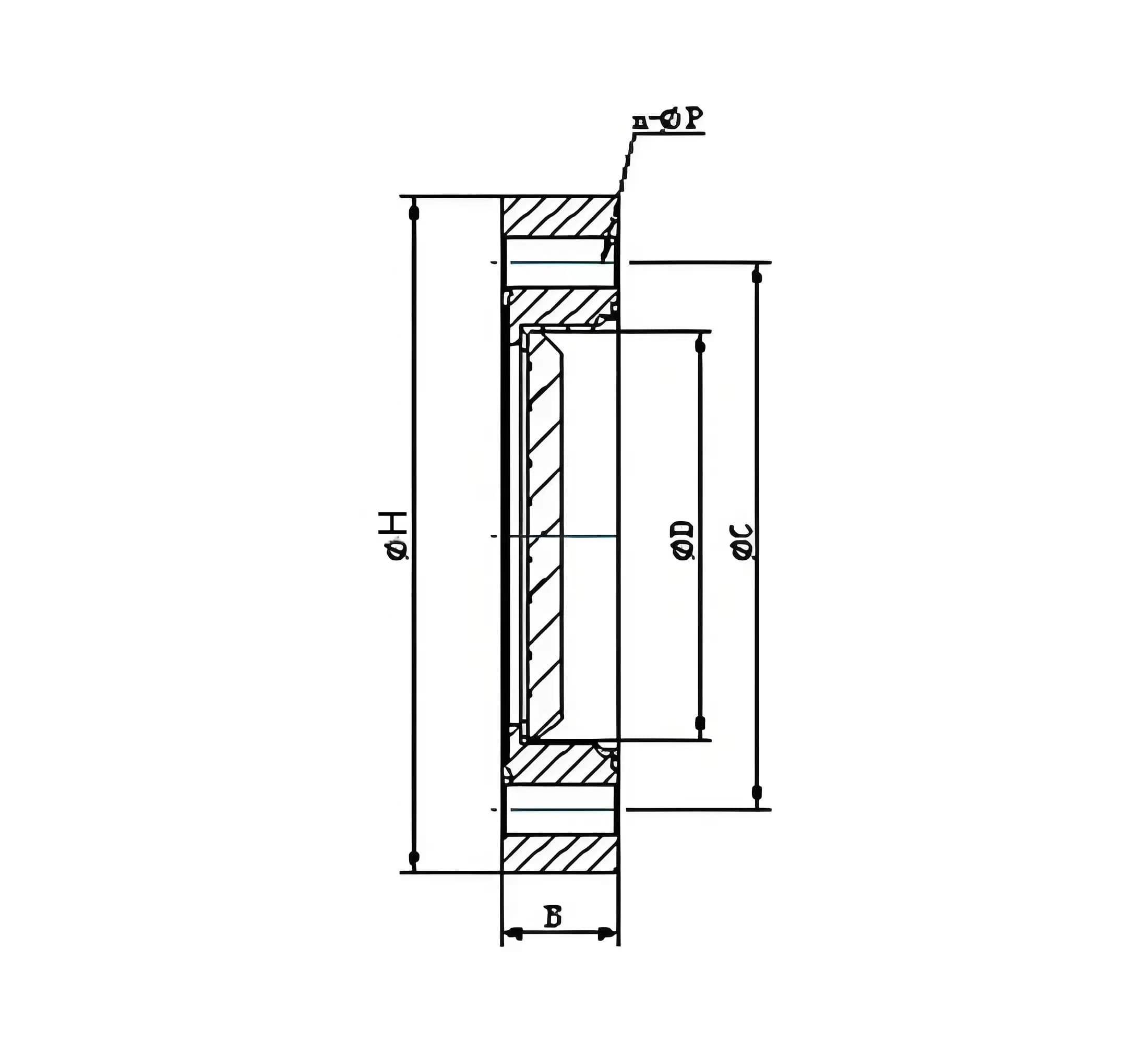

Visual inspection of the CF Ultra-High Vacuum Observation Window Flange, showcasing its construction and components.

Technical Specifications

Detailed dimensions and model information for the CF Ultra-High Vacuum Observation Window Flange series with high borosilicate glass.

| Model | ΦH | ΦC | ΦD (Clear View Diameter) | n-ΦP | B (Glass Thickness) |

|---|---|---|---|---|---|

| CF 16 | 34 | 27 | 14 | 6-Φ4.3 | 18 |

| CF 25 | 54 | 43 | 23 | 6-Φ6.6 | 14 |

| CF 35 | 70 | 58.7 | 38 | 6-Φ6.6 | 16 |

| CF 50 | 86 | 72.4 | 50 | 8-Φ8.4 | 17 |

| CF 63 | 114 | 92.2 | 62 | 8-Φ8.4 | 20 |

| CF 100 | 152 | 130.3 | 95 | 16-Φ8.4 | 20 |

| CF 150 | 202 | 181.1 | 146 | 20-Φ8.4 | 22 |

| CF 200 | 253 | 231.9 | 146 | 24-Φ8.4 | 24.5 |

Product Overview: Precision Viewing in Ultra-High Vacuum

The KINTEK CF Ultra-High Vacuum Observation Window Flange, featuring a high borosilicate glass sight glass, is meticulously engineered for demanding environments requiring ultra-high vacuum conditions (typically above 10-9 Torr). It provides a reliable and clear viewing port essential for monitoring and controlling processes in high-end scientific research and advanced industrial applications. Leveraging our R&D expertise and in-house manufacturing, we offer both standard and deeply customized solutions to meet your specific experimental needs.

Key Features

High Borosilicate Glass Sight Glass

- Exceptional Thermal Stability: Operates effectively across a wide temperature range (-200°C to +300°C) with a very low thermal expansion coefficient (3.3 x 10-6/K), minimizing distortion and maintaining integrity under thermal stress.

- Superior Chemical Resistance: Highly resistant to acid and alkali corrosion, ensuring durability and a long service life even in reactive environments.

- Optimal Optical Clarity: Delivers over 92% light transmittance for clear, unobstructed observation of processes within the vacuum chamber.

Robust Stainless Steel Flange

- UHV Compatibility & Durability: Constructed from high-quality stainless steel (typically 304L or 316L) for high strength, excellent corrosion resistance, and suitability for ultra-high vacuum applications.

- Reliable Sealing Performance: Precision engineered with CF knife-edge design to ensure a robust and leak-tight seal when used with an appropriate gasket, critical for maintaining stable ultra-high vacuum environments.

Designed for Versatility and Integration

- Broad Range of Specifications: Available in multiple CF flange sizes (from CF16 to CF200 and beyond) and various high borosilicate glass dimensions to suit diverse equipment and experimental setups.

- CF Standard Compliance: Ensures easy installation, interchangeability with other CF components, and straightforward maintenance, saving valuable time and effort.

Advantages for Your Critical Applications

- Unwavering Reliability in UHV: The synergistic design of high-quality borosilicate glass and stainless steel ensures consistent, stable operation, crucial for sensitive ultra-high vacuum processes.

- Enhanced Process Monitoring: Achieve precise control and detailed observation thanks to the exceptional clarity, stability, and minimal outgassing of the viewing window.

- Adaptable to Your Unique Requirements: Beyond our standard offerings, KINTEK’s strong deep customization capability allows us to tailor flanges to your specific dimensions, alternative glass materials (e.g., sapphire, quartz), anti-reflective coatings, or other unique requirements. Discuss your custom project with our experts.

- Long-Term Value: Durable materials, robust construction, and careful manufacturing lead to a prolonged service life and reduced maintenance, offering an excellent return on investment for your critical UHV systems.

Typical Applications

This CF observation window flange with high borosilicate glass is indispensable for a variety of UHV and HV applications, including:

- Semiconductor Manufacturing: Critical for in-situ observation during wafer processing, PVD, CVD, and etching.

- Vacuum Coating Systems: Essential for real-time monitoring of thin-film deposition processes and coating quality.

- Optical Instruments & Laser Systems: Provides clear optical access for internal components and beam paths in vacuum.

- Aerospace & Space Simulation Chambers: Supports research and testing in environments mimicking the vacuum of space.

- Advanced Scientific Research: Facilitates detailed observation in surface science (e.g., XPS, AES, LEED), particle accelerators, fusion research, and materials science experiments.

- Industrial Vacuum Processes: Used in vacuum furnaces, electron beam welding, and other high-vacuum industrial equipment requiring visual monitoring.

Working Principle

The CF ultra-high vacuum observation window flange operates by creating a hermetically sealed viewing port into a vacuum chamber. The high borosilicate glass serves as the transparent barrier, selected for its excellent optical properties, thermal stability (low expansion coefficient), and chemical resistance. The stainless steel CF flange utilizes a knife-edge sealing principle: when bolted to a mating CF flange with a soft metal gasket (typically oxygen-free copper) in between, the knife edges indent the gasket, creating an extremely reliable metal-to-metal seal capable of maintaining ultra-high vacuum conditions. This robust design allows for direct visual or instrumental observation of internal processes without compromising the integrity of the vacuum environment.

Connect with KINTEK for Your UHV Solutions

At KINTEK, we combine exceptional R&D capabilities with precision in-house manufacturing to deliver advanced UHV components tailored to your needs. Whether you require a standard CF observation window flange with high borosilicate glass or a fully customized solution for a unique application, our experienced team is ready to provide expert support.

Ready to enhance your UHV system with a high-quality, reliable observation window? We invite you to discuss your specific requirements, request a detailed quotation, or explore our extensive customization options. Please fill out the contact form below, and one of our technical specialists will be in touch shortly to assist you.

Trusted by Industry Leaders

4.8 / 5

Incredible clarity and durability! Perfect for our lab setup. Highly recommend!

4.7 / 5

Fast shipping and top-notch quality. Worth every penny!

4.9 / 5

The glass is flawless and the flange fits perfectly. A game-changer!

4.8 / 5

Exceptional product for high vacuum applications. Very impressed!

4.7 / 5

Great value for money. The quality exceeds expectations!

4.9 / 5

Precision engineering at its best. Delivered faster than expected!

4.8 / 5

Perfect for our research needs. The glass is crystal clear and sturdy!

4.7 / 5

Reliable and high-performance. Exactly what we needed!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Ultra High Vacuum CF Flange Stainless Steel Sapphire Glass Observation Sight Window

CF sapphire viewing window for ultra-high vacuum systems. Durable, clear, and precise for semiconductor and aerospace applications. Explore specs now!

Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

KF Ultra-High Vacuum Observation Window with borosilicate glass for clear viewing in demanding vacuum environments. Durable 304 stainless steel flange ensures reliable sealing.

Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

KF flange observation window with sapphire glass for ultra-high vacuum. Durable 304 stainless steel, 350℃ max temperature. Ideal for semiconductor and aerospace.

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Reliable CF/KF flange vacuum electrode feedthrough for high-performance vacuum systems. Ensures superior sealing, conductivity & durability. Customizable options available.

Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

KF/ISO/CF ultra-high vacuum stainless steel flange pipe systems for precision applications. Customizable, durable, and leak-tight. Get expert solutions now!

HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

KINTEK's HFCVD system delivers high-quality nano-diamond coatings for wire drawing dies, enhancing durability with superior hardness and wear resistance. Explore precision solutions now!

Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

Premium KF/ISO stainless steel vacuum blind plates for high-vacuum systems. Durable 304/316 SS, Viton/EPDM seals. KF & ISO connections. Get expert advice now!

RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

KINTEK RF PECVD System: Precision thin-film deposition for semiconductors, optics & MEMS. Automated, low-temperature process with superior film quality. Custom solutions available.

Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

KINTEK MPCVD Systems: Grow high-quality diamond films with precision. Reliable, energy-efficient, and beginner-friendly. Expert support available.

Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

Ultra-High Vacuum Flange Aviation Plug Connector for aerospace & labs. KF/ISO/CF compatible, 10⁻⁹ mbar airtight, MIL-STD certified. Durable & customizable.

Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Discover KINTEK's Hydrogen Atmosphere Furnace for precise sintering & annealing in controlled environments. Up to 1600°C, safety features, customizable.

1700℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-17A Controlled Atmosphere Furnace: Precise 1700°C heating with vacuum & gas control. Ideal for sintering, research & material processing. Explore now!

1400℃ Controlled Inert Nitrogen Atmosphere Furnace

KT-14A Controlled Atmosphere Furnace for labs & industry. 1400°C max temp, vacuum sealing, inert gas control. Customizable solutions available.

1200℃ Controlled Inert Nitrogen Atmosphere Furnace

KINTEK 1200℃ Controlled Atmosphere Furnace: Precision heating with gas control for labs. Ideal for sintering, annealing, and material research. Customizable sizes available.

Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

KINTEK Mesh Belt Furnace: High-performance controlled atmosphere furnace for sintering, hardening & heat treatment. Customizable, energy-efficient, precise temperature control. Get a quote now!

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.