The Invisible Stage

Imagine an aerospace engineer tasked with brazing a turbine blade. The joint must be flawless. A few stray atoms of carbon could compromise the alloy's integrity, leading to catastrophic failure miles above the earth.

Or consider a materials scientist developing a new medical implant. The material must be biocompatibly pure. Any surface contamination from the manufacturing process is not just an imperfection; it's a risk to a patient's health.

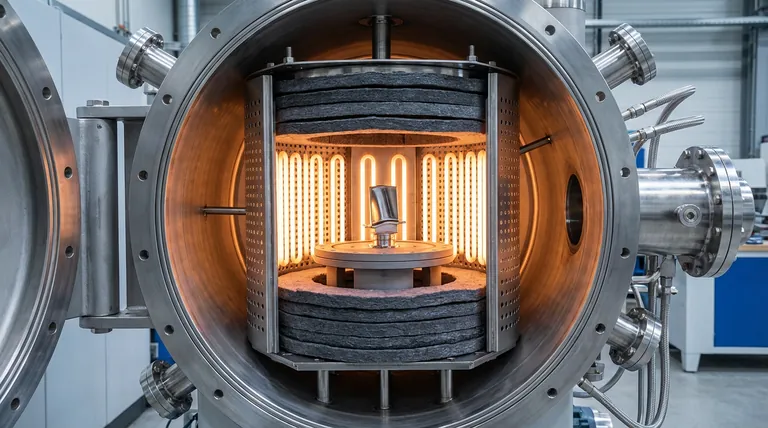

These high-stakes processes unfold on an invisible stage: the hot zone of a vacuum furnace. It is a sealed world where extreme heat, deep vacuum, and material science converge. The success of the entire operation depends on the thoughtful engineering of this core component.

The Anatomy of Control

The hot zone is more than a heated box; it's a precisely controlled environment. Its design is a story of deliberate choices, each one a calculated trade-off between performance, durability, and purity.

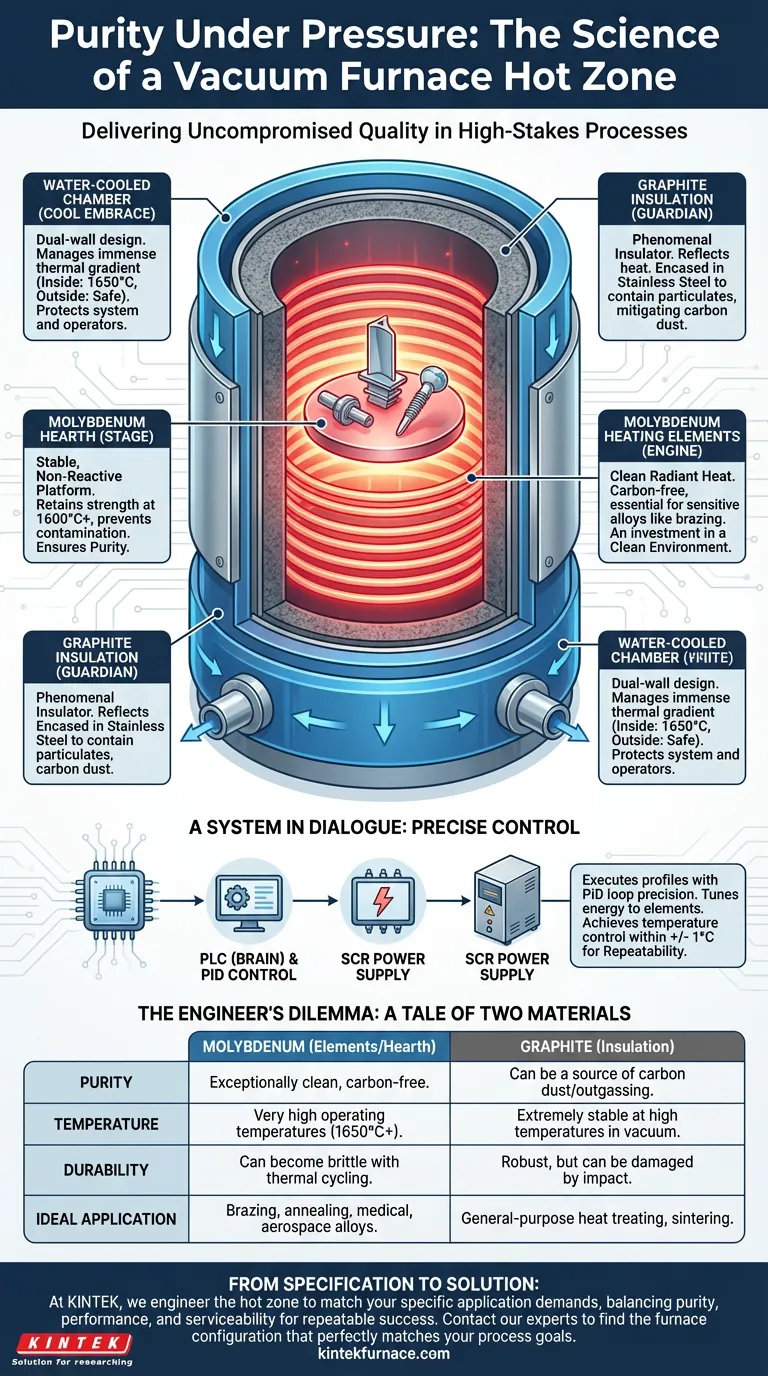

The Stage: Molybdenum Hearth

The foundation of the work zone is the hearth assembly. In a high-performance system, this is often made of pure molybdenum. Why? Because at 1600°C, most metals have become liquid or pliable. Molybdenum, a refractory metal, retains its strength, providing a stable, non-reactive platform. It won't contaminate the parts it holds, ensuring the process starts and ends with purity.

The Engine: Molybdenum Heating Elements

Heat is the prime mover, generated by powerful heating elements. Using molybdenum bands is a critical choice. These elements provide exceptionally clean radiant heat, free from the carbon that could be introduced by graphite heaters. For processes like brazing or annealing sensitive alloys, this choice is non-negotiable. It is an investment in a clean environment.

The Guardian: Graphite Insulation

Surrounding this metallic core is a wall of graphite insulation. Here lies the engineer's elegant compromise. Graphite is a phenomenal insulator in a vacuum, lightweight and incredibly effective at reflecting heat back into the work zone.

However, it's a source of carbon dust and can release absorbed gases. The solution? Smart design. High-quality systems encase the graphite in stainless steel, containing potential particulates and harnessing graphite's insulating power while mitigating its primary drawback.

A System in Dialogue

The hot zone doesn't work in isolation. Its performance is a constant dialogue with the larger furnace system, a symphony of interconnected parts working to maintain a state of extreme control.

The Cool Embrace: The Water-Cooled Chamber

A paradox of furnace design is managing an immense thermal gradient. The inside might be 1650°C (3000°F), while the outside must remain safe to the touch. This is accomplished with a dual-wall, water-cooled stainless steel chamber. It's the robust vessel that contains the vacuum and actively removes waste heat, protecting both the system and its operators.

The Conductor: PLC & PID Control

No human hand could maintain the required thermal stability. The system's brain is a PLC (Programmable Logic Controller) executing heating profiles with the precision of a PID loop. An SCR Power Supply finely tunes the energy sent to the elements, achieving temperature control within +/- 1°C. This is the key to repeatability—ensuring the process on Monday is identical to the one on Friday.

The Engineer's Dilemma: A Tale of Two Materials

The choice to combine a molybdenum heart with graphite insulation is not accidental; it’s a solution born from understanding the fundamental trade-offs.

| Feature | Molybdenum (Elements/Hearth) | Graphite (Insulation) |

|---|---|---|

| Purity | Exceptionally clean, carbon-free environment. | Can be a source of carbon dust and outgassing. |

| Temperature | Very high operating temperatures (up to 1650°C+). | Extremely stable at high temperatures in a vacuum. |

| Durability | Can become brittle with thermal cycling. | Robust, but can be damaged by mechanical impact. |

| Ideal Application | Brazing, annealing, medical, aerospace alloys. | General-purpose heat treating, sintering. |

This hybrid design delivers the best of both worlds: the ultra-clean heating of molybdenum where it matters most—in direct proximity to the workload—and the cost-effective, high-efficiency insulation of graphite.

From Specification to Solution

Understanding this design philosophy is crucial when selecting a furnace. The goal isn't just to buy a machine that reaches a certain temperature; it's to acquire a tool whose engineering principles align with your process requirements.

This level of design consideration—balancing purity, performance, and serviceability—is the core principle behind advanced laboratory furnaces. At KINTEK, we build our systems on a deep understanding of these material interactions. Our expertise lies not only in manufacturing a range of Muffle, Tube, Vacuum, and CVD furnaces but in customizing them to meet unique challenges. We engineer the hot zone—the very heart of the furnace—to match the specific demands of your application, ensuring the result is not just successful, but repeatable.

Whether you're pushing the boundaries of material science or manufacturing critical components, the right configuration is your most important asset. It's a strategic partnership with the laws of physics.

To find the furnace configuration that perfectly matches your process goals, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

Related Articles

- Beyond the Parts List: The Real Reason Your Vacuum Hot Press Fails (And How to Fix It)

- Why Your High-Purity Metals Oxidize in a Perfect Vacuum—And How to Stop It

- Why Your Vacuum Furnace Failed After the Lab Move—And How to Prevent It

- How Vacuum Pressure Sintering Furnaces Elevate Material Performance Across Industries

- Why Your High-Temperature Materials Fail: The Hidden War Inside Your Furnace