The Illusion of Simple Heat

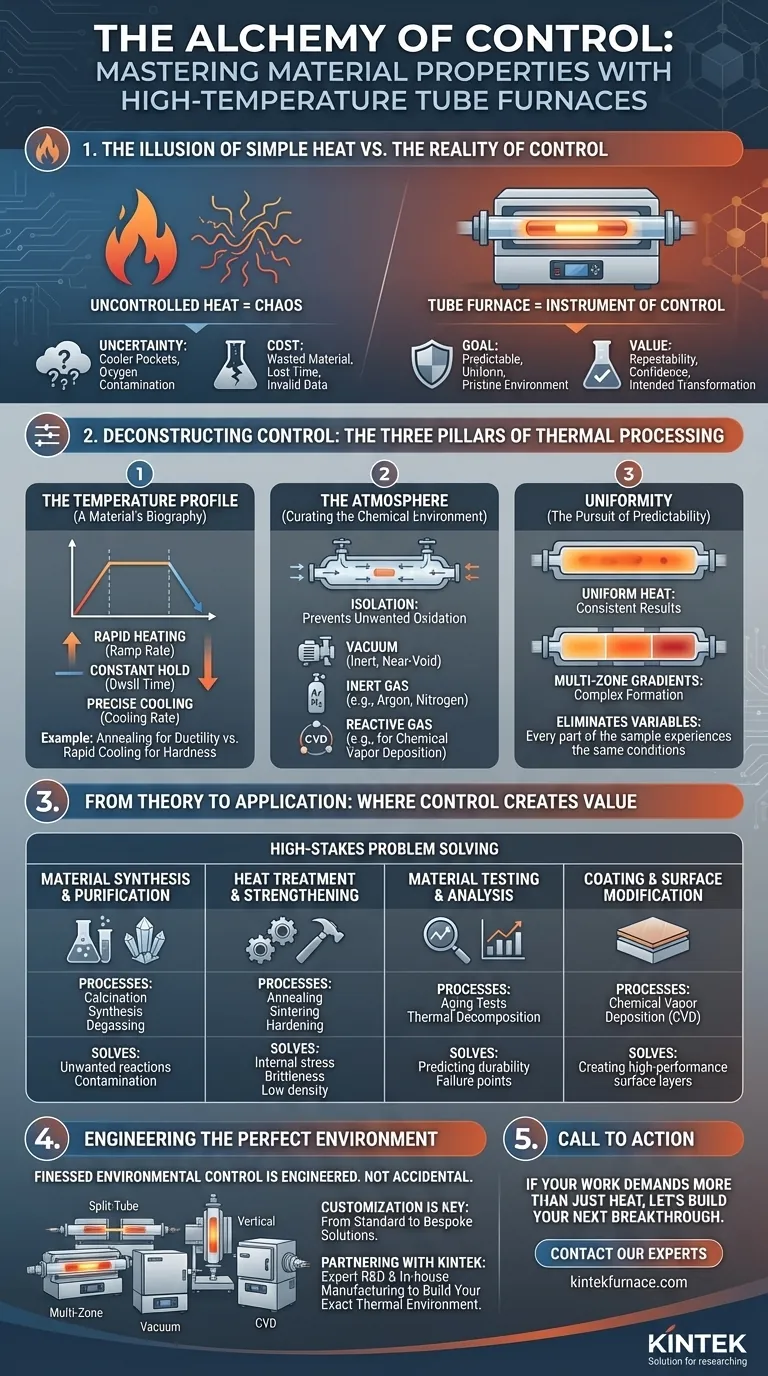

We tend to think of a furnace as a simple tool: its job is to get hot. But in the world of materials science, chemistry, and engineering, this is a profound oversimplification. Uncontrolled heat is just chaos.

The real challenge for any researcher isn't just reaching a target temperature. It's about eliminating uncertainty. A single uncontrolled variable—a pocket of cooler air, a trace of oxygen—can invalidate months of work. The cost isn't just wasted material; it's lost time and a loss of confidence in your own data.

This is the psychological core of scientific work. We crave repeatability. We need to know that a result achieved today can be achieved again tomorrow.

A high-temperature tube furnace, then, is not merely a heater. It is an instrument of control. Its true value lies in its ability to create a highly predictable, uniform, and pristine environment where matter can be transformed with intention.

Deconstructing Control: The Three Pillars of Thermal Processing

Mastery over a material’s properties comes from manipulating three fundamental variables. Modern furnace systems are engineered to give scientists precise command over each one.

Pillar 1: The Temperature Profile - A Material's Biography

The final properties of a material are not just defined by the peak temperature it experiences, but by its entire thermal journey. This journey is called the temperature profile.

- Ramp Rate: How quickly the temperature rises.

- Dwell Time: How long the temperature is held constant.

- Cooling Rate: How slowly or quickly the temperature falls.

Programming this profile is like writing a biography for the material. A rapid heating and cooling cycle might create hardness in a steel alloy, while a long, slow cooling process (annealing) removes internal stresses, making it more ductile. The control is so fine that the process becomes a predictable recipe for a desired outcome.

Pillar 2: The Atmosphere - Curating the Chemical Environment

Many critical processes fail in the presence of normal air. At high temperatures, oxygen is highly reactive, leading to unwanted oxidation that can ruin a sample.

A tube furnace solves this by isolating the material inside a tube, allowing for complete control over the atmosphere.

- Vacuum: By pumping out the air, a near-vacuum is created, providing a truly inert environment.

- Inert Gas: Introducing gases like argon or nitrogen prevents unwanted chemical reactions.

- Reactive Gas: Intentionally introducing specific gases can be part of the process itself, as seen in Chemical Vapor Deposition (CVD), where gases react to form a thin film on a substrate.

The furnace becomes a sealed universe where the chemical stage is set exactly as the researcher intends.

Pillar 3: Uniformity - The Pursuit of Predictability

If one end of your sample is at 1100°C and the other is at 1050°C, you don't have one experiment—you have an infinite number of experiments running simultaneously. The results are meaningless.

High-quality tube furnaces provide an exceptionally uniform temperature zone across the entire length of the sample. For even more complex tasks, like growing a single perfect crystal, multi-zone furnaces can create precise temperature gradients, guiding the formation of the material's structure with surgical precision.

From Theory to Application: Where Control Creates Value

When these pillars of control are applied, a tube furnace becomes a versatile tool for solving specific, high-stakes problems.

| Application Category | Key Processes | Solves the Problem Of... |

|---|---|---|

| Material Synthesis & Purification | Calcination, Synthesis, Degassing | Unwanted side reactions and contamination. |

| Heat Treatment & Strengthening | Annealing, Sintering, Hardening | Internal stress, brittleness, or low density. |

| Material Testing & Analysis | Aging Tests, Thermal Decomposition | Predicting long-term durability and failure points. |

| Coating & Surface Modification | Chemical Vapor Deposition (CVD) | Creating ultra-thin, high-performance surface layers. |

The Metallurgist’s Dilemma: Forging Strength from Brittleness

A newly forged metal part might be strong, but it's also brittle, riddled with invisible internal stresses. Under load, it could shatter. By placing it in a tube furnace and running a precise annealing cycle—heating it just enough and then cooling it with excruciating slowness—the metallurgist allows the material’s crystalline structure to relax and realign. The stress vanishes, replaced by resilience.

The Chemist's Canvas: Synthesizing Purity from Chaos

Creating the next generation of semiconductor materials or purifying a pharmaceutical compound requires absolute purity. A tube furnace with precise atmospheric control acts as a chemical cleanroom. It purges reactive oxygen and introduces a specific inert environment, ensuring that the only reaction taking place is the one the chemist designed. The result is purity by design, not by chance.

Engineering the Perfect Environment

True progress in materials science comes from moving beyond brute-force heating to finessed environmental control. Achieving this level of control is not accidental; it is engineered. The design of the furnace itself—whether it's a split-tube for rapid cooling, a vertical orientation for molten samples, or a multi-zone system for complex gradients—must match the specific demands of the research.

This is why a one-size-fits-all approach is insufficient for cutting-edge work. At KINTEK, we specialize in building the precise thermal environment your research requires. Backed by expert R&D and in-house manufacturing, our portfolio of Muffle, Tube, Rotary, and Vacuum Furnaces, along with advanced CVD systems, serves as the foundation. Our true strength, however, lies in deep customization—partnering with you to engineer a solution that provides the exact control you need to turn theory into reality.

If your work demands more than just heat, let's build the environment where your next breakthrough can happen. Contact Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

Related Articles

- A War Against Chaos: The Elegant Engineering of the Modern Tube Furnace

- The Physics of Control: Mastering the Three-Stage Journey of Heat in a Tube Furnace

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- The Art of Isolation: Mastering Material Properties with Tube Furnaces