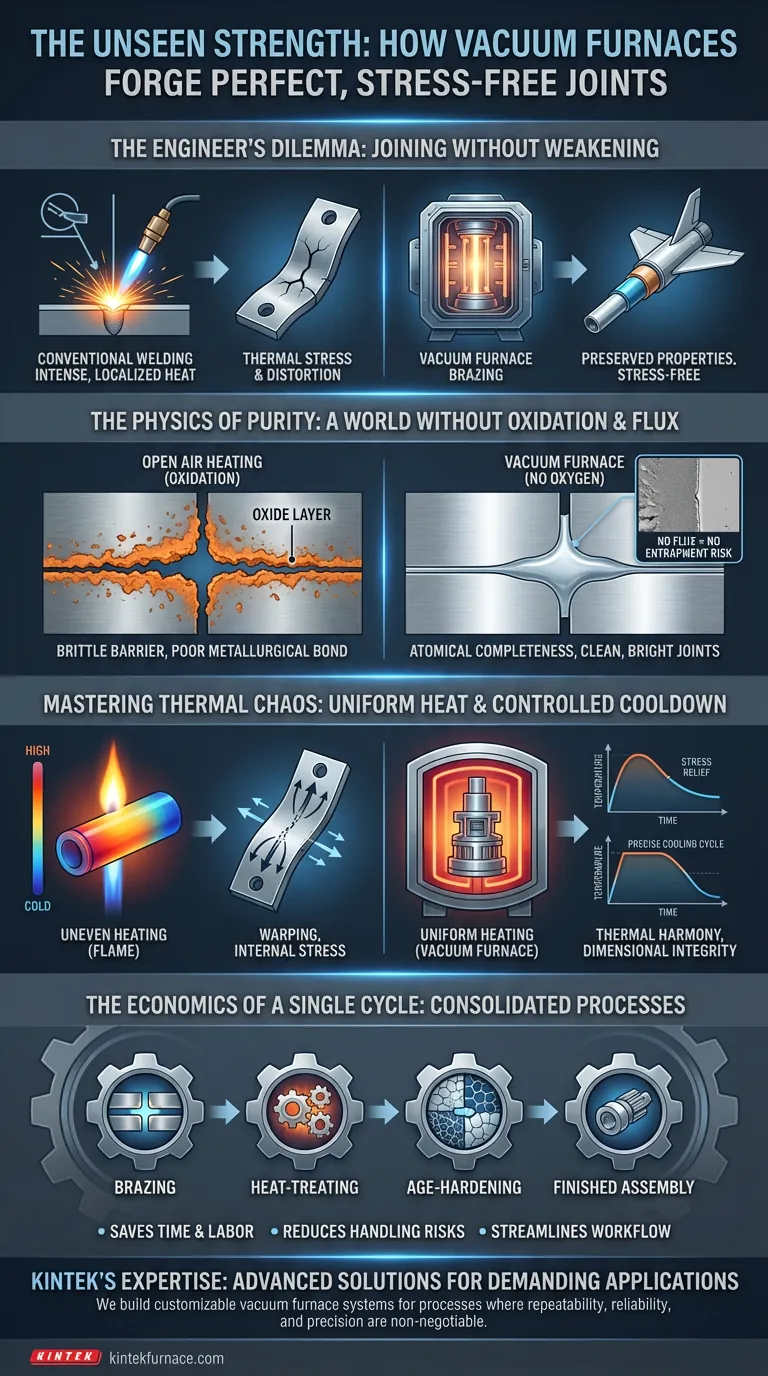

The Engineer's Dilemma: Joining Without Weakening

Imagine a complex aerospace component. It’s an assembly of dissimilar metals and thin-walled structures, designed to be both lightweight and incredibly strong. The conventional answer for joining is welding, a process of intense, localized heat.

But this violence introduces a hidden flaw: thermal stress. The material warps, its internal structure compromised. The very act of joining it creates a point of future failure.

This is the core challenge in advanced manufacturing. How do you join materials without undoing their carefully engineered properties? The answer lies not in more force, but in absolute control—the kind only found in the perfect void of a vacuum furnace.

The Physics of Purity

The strength of a vacuum-brazed joint begins with what isn't there: atmosphere. By removing reactive gases like oxygen, we fundamentally change the rules of metallurgy.

A World Without Oxidation

When you heat metal in the open air, its surface instantly forms an oxide layer. This brittle, non-metallic crust acts as a barrier, preventing a true metallurgical bond. It’s like trying to glue two dusty surfaces together.

A vacuum furnace removes virtually all oxygen. This allows the filler metal to interact with a perfectly clean, pure parent material. The result is a bond that is not merely adhesive, but atomically complete. The parts emerge from the furnace bright and clean, requiring no post-process cleaning.

The Flaw in Flux

Traditional brazing solves the oxide problem with chemical flux. But flux is a necessary evil. It can get trapped within the joint, creating a hidden pocket of corrosion that can cause catastrophic failure months or years later.

Vacuum brazing makes flux obsolete. The inherent purity of the environment eliminates the risk of flux entrapment entirely. This isn't just a cleaner process; it's a psychologically freeing one, removing a significant variable of doubt from high-stakes applications.

Mastering Thermal Chaos

The second enemy of a perfect joint is thermal stress. Uneven heating and cooling forces materials to expand and contract at different rates, locking in stress that leads to distortion and weakness.

The Discipline of Uniform Heat

A vacuum furnace doesn't attack a component with a localized flame. Instead, it slowly and uniformly raises the temperature of the entire assembly.

Every part—thick or thin, steel or ceramic—reaches the brazing temperature at the same time. This thermal harmony prevents the internal tug-of-war that causes warping. The filler metal flows evenly into the joint through capillary action, drawn into the tightest gaps to create a solid, void-free bond.

The Art of a Controlled Cooldown

Just as important as the heating is the cooling. A precisely controlled cooling cycle allows the joined assembly to settle, relieving internal stresses naturally. This preserves the material’s original temper, dimensions, and metallurgical integrity.

This level of control is simply impossible with methods that expose the part to open air.

The Economics of a Single Cycle

While the quality of the joint is paramount, the true efficiency of vacuum brazing is revealed in its ability to consolidate processes. Why handle a part three times when you can do it once?

A modern vacuum furnace is more than a brazing tool; it's a complete thermal processing station.

- Brazing: Creating the strong, clean joint.

- Heat-Treating: Hardening or annealing the assembly to desired specifications.

- Age-Hardening: Completing the metallurgical process in the same cycle.

This consolidation saves enormous amounts of time, energy, and labor. It eliminates the risks associated with moving high-value parts between different machines, streamlining the entire production workflow.

The Paradox: Success Demands Investment

The pristine results of vacuum brazing are not achieved without discipline. This is a demanding process that rewards meticulousness.

- The Mandate for Cleanliness: Any contaminant—oil, grease, even a fingerprint—will vaporize in the vacuum and ruin the entire batch. Parts must be surgically clean before entering the furnace.

- The Investment in Equipment: A high-vacuum furnace is a sophisticated piece of capital equipment. It requires expertise to operate and represents a significant investment.

This is precisely why the choice of furnace is critical. For processes where repeatability, reliability, and precision are non-negotiable, a generic solution is insufficient. You need a system built for the specific thermal profiles and material challenges you face.

KINTEK's expertise lies here. Backed by deep R&D and in-house manufacturing, we build advanced, customizable vacuum furnace systems designed for the most demanding applications. Whether joining reactive alloys or bonding metals to ceramics, our furnaces provide the control and purity required to turn complex engineering challenges into manufacturing successes.

If your work demands joints that are not just strong, but fundamentally perfect, the controlled world of a vacuum furnace is your solution. Contact Our Experts

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- Beyond the Bond: The Physics and Psychology of Vacuum Furnace Brazing

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Engineering for Zero Failure: The Indispensable Role of Vacuum Furnaces in Aerospace

- The Unseen Enemy: How Vacuum Furnaces Redefine Material Perfection