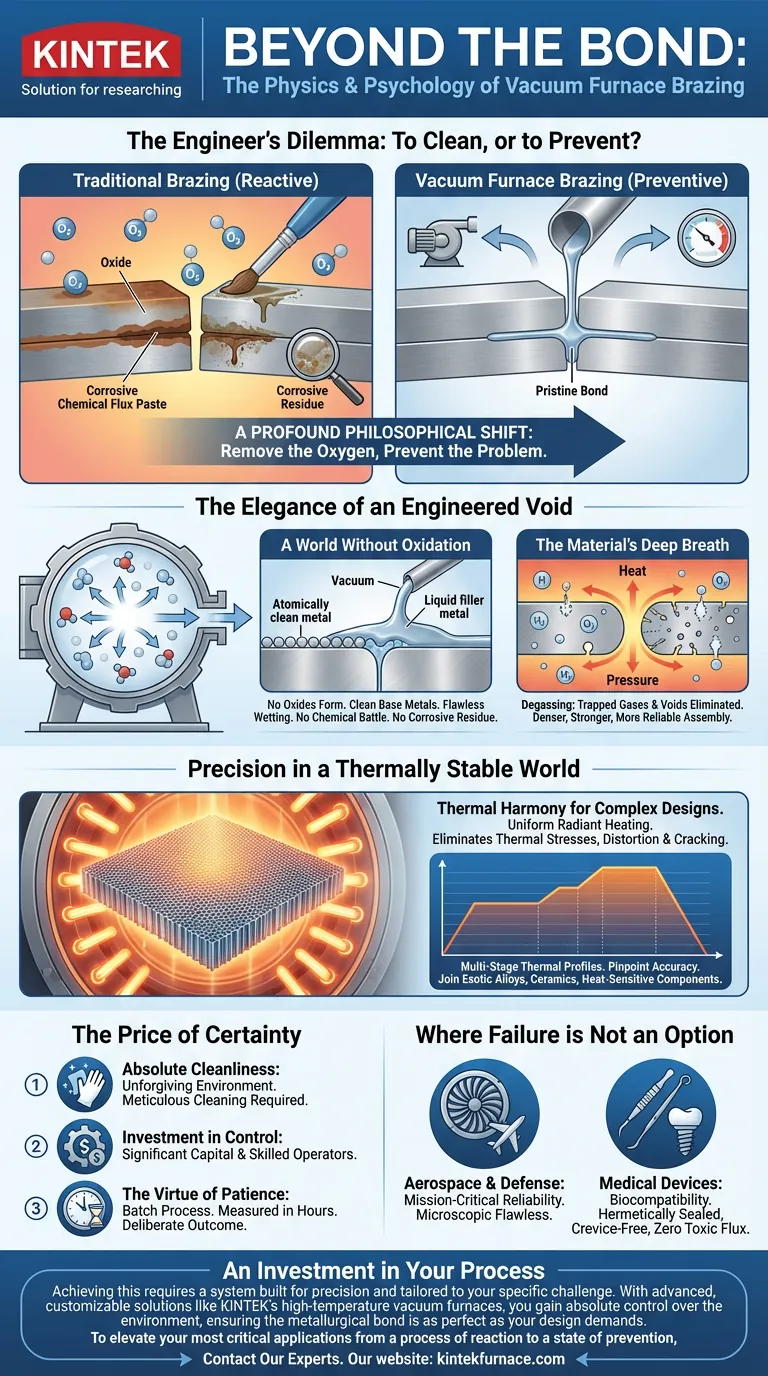

The Engineer's Dilemma: To Clean, or to Prevent?

Every high-stakes engineering project eventually confronts the same fundamental choice: Do you design a system that reacts to problems, or one where problems cannot exist in the first place?

When joining two pieces of metal, the problem is oxygen. At high temperatures, oxygen aggressively bonds with metal surfaces, forming a brittle, insulating layer of oxide. This layer acts as a wall, preventing a true metallurgical bond.

The traditional solution is reactive. You apply a chemical flux—an aggressive, corrosive paste—to dissolve the oxides as they form. It's a brute-force cure. But it leaves behind a residue that must be meticulously cleaned, lest it corrode the very joint it helped create.

Vacuum furnace brazing represents a profound philosophical shift. It doesn’t fight the fire; it removes the oxygen.

The Elegance of an Engineered Void

The most powerful tool in vacuum brazing is not what's in the furnace, but what is taken out. By evacuating the atmosphere, we create a chemically pristine environment.

A World Without Oxidation

Without oxygen, oxides simply cannot form. The base metals remain atomically clean and receptive as they reach brazing temperature. The liquid filler metal flows freely via capillary action, wetting every surface and creating a continuous, flawless metallurgical bond.

There is no chemical battle, no corrosive residue, and no need for aggressive post-process cleaning. The process is defined by an elegant simplicity born from absolute environmental control.

The Material's Deep Breath

The vacuum does more than protect surfaces. It actively improves the material itself.

As the metals heat up, the negative pressure pulls trapped gases—like hydrogen and oxygen—out from deep within the material’s crystalline structure. This "degassing" effect eliminates microscopic voids, resulting in a denser, stronger, and more reliable final assembly. The material, in essence, is allowed to exhale its own impurities.

Precision in a Thermally Stable World

A vacuum furnace is more than an empty chamber; it's an instrument of unparalleled thermal precision. This control is critical when failure carries catastrophic consequences.

Thermal Harmony for Complex Designs

Imagine brazing a delicate honeycomb structure for an aerospace heat exchanger. Radiant heating within a vacuum ensures every strut, fin, and surface heats and cools at the same, controlled rate.

This uniformity eliminates the thermal stresses that cause distortion and cracking in complex geometries or when joining metals of vastly different thicknesses. It’s a gentle, predictable process that respects the integrity of the entire assembly.

The Discipline of Temperature

Modern vacuum furnaces allow for programmable, multi-stage thermal profiles with pinpoint accuracy. This enables engineers to confidently braze exotic alloys, join ceramics to metal, or protect heat-sensitive components located near the joint. The process becomes repeatable, reliable, and entirely predictable.

The Price of Certainty

This level of perfection is not without its demands. It is a process that trades convenience for certainty.

- Absolute Cleanliness: The vacuum environment is unforgiving. Any contaminants like oils or grease will vaporize and contaminate the entire system. Parts must be meticulously cleaned before entering the furnace.

- Investment in Control: Vacuum furnaces are a significant capital investment, requiring skilled operators who understand the interplay between vacuum levels, temperature, and material science.

- The Virtue of Patience: Brazing is a batch process. The cycles of pumping down the vacuum, heating, soaking, and cooling are measured in hours, not minutes. It’s a deliberate process for when the outcome cannot be left to chance.

Where Failure is Not an Option

The uncompromising quality of vacuum brazing makes it the non-negotiable standard in the world's most demanding industries.

- Aerospace & Defense: A turbine blade spinning at thousands of RPM or a critical fuel line fitting cannot have a microscopic flaw. The strength, purity, and low weight of vacuum-brazed joints are essential for mission-critical reliability.

- Medical Devices: For surgical tools and permanent implants, biocompatibility is paramount. Vacuum brazing creates hermetically sealed, crevice-free joints with zero toxic flux residue, ensuring patient safety.

An Investment in Your Process

Ultimately, choosing a joining method is a choice of philosophy. Atmospheric brazing with flux is a valid, cost-effective solution for many applications. But for the most critical components, you are not just joining metal; you are engineering certainty.

Achieving this requires a system built for precision and tailored to your specific challenge. With advanced, customizable solutions like KINTEK’s high-temperature vacuum furnaces, you gain absolute control over the environment, ensuring the metallurgical bond is as perfect as your design demands. To elevate your most critical applications from a process of reaction to a state of prevention, Contact Our Experts.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- More Than Heat: The Physics and Psychology of Vacuum Furnace Design

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- More Than a Void: The Inherent Energy Efficiency of Vacuum Furnace Design

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- Beyond the Heat: The Psychology of Perfect Vacuum Furnace Operation