It’s a familiar story for many materials scientists. After days or even weeks of a carefully planned Chemical Vapor Transport (CVT) experiment, you eagerly open the furnace. You’re hoping to find pristine, high-purity single crystals. Instead, you’re met with disappointment: a dusting of unreacted powder, a collection of tiny, poorly formed crystallites, or worse, nothing at all.

Your lab notebook fills up with questions. Was the vacuum seal tight enough? Did I use the right amount of transport agent? Is my starting material impure? You tweak a variable, run the entire process again, and get yet another unpredictable result. This isn't just frustrating; it's a significant bottleneck, burning through valuable time, expensive materials, and delaying critical research milestones.

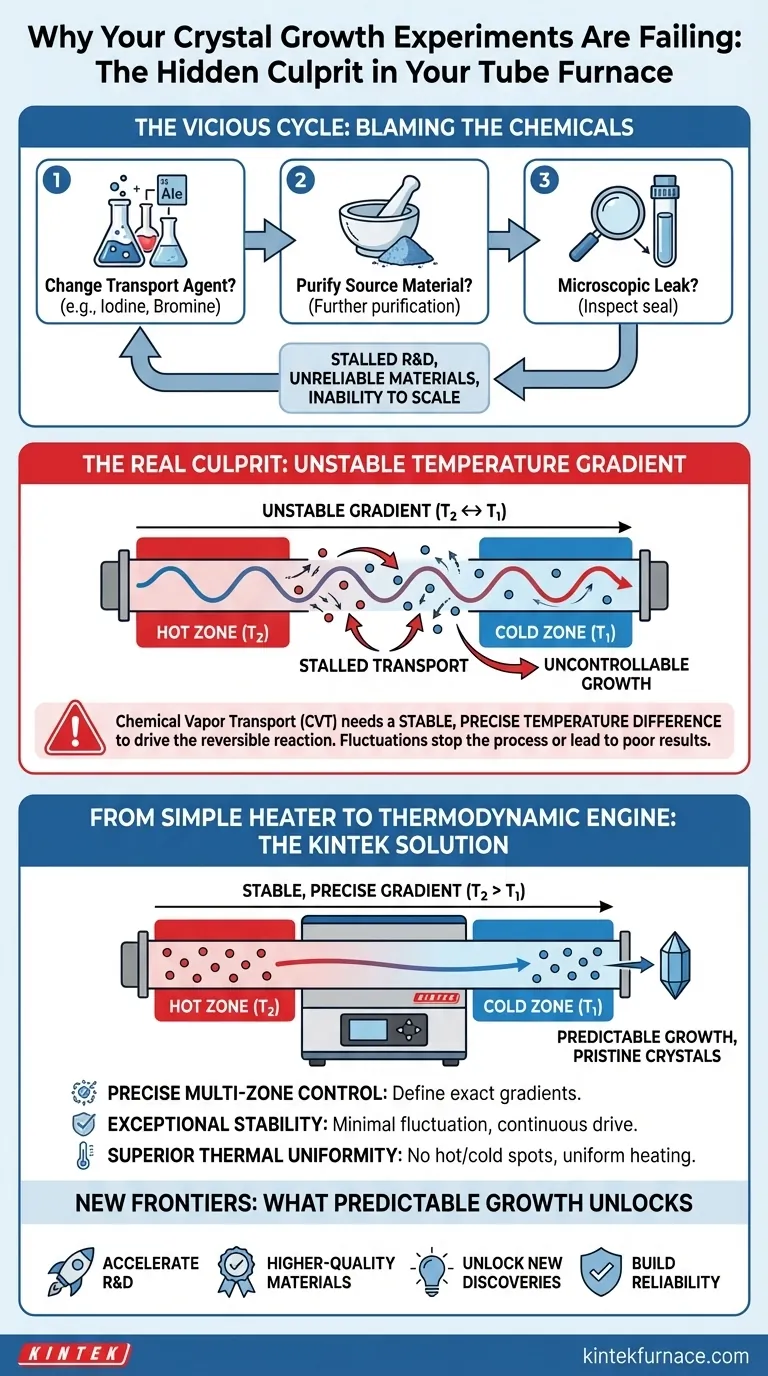

The Vicious Cycle: Blaming the Chemicals, Ignoring the Engine

When a CVT process fails, the immediate instinct is to troubleshoot the chemistry inside the sealed ampoule. This leads to a trial-and-error loop that feels scientific but often misses the point entirely. Researchers find themselves asking:

- "Should I change the transport agent?" You try iodine, bromine, or tellurium tetrachloride, each attempt adding another week to the timeline.

- "Is the source material the problem?" You spend time and resources further purifying your starting powder, hoping it will make a difference.

- "Was there a microscopic leak?" You become an expert in vacuum grease and quartz tube inspection, re-running experiments with obsessive attention to the seal.

While all these factors are important, they are often just passengers in a vehicle that is fundamentally malfunctioning. The harsh business reality of this cycle is stalled R&D projects, unreliable material properties that kill product prototypes, and an inability to scale discoveries from the lab to practical applications. You're stuck troubleshooting the process instead of innovating with the results.

The Real Culprit: Why an Unstable Temperature Gradient Sabotages Your Work

The breakthrough comes when you shift your focus from what's inside the tube to the environment around it. The entire CVT process is a delicate thermodynamic balancing act, and the tube furnace is its engine.

The core principle of CVT is a reversible chemical reaction driven by a temperature difference.

- In a hot zone (T₂), your material reacts with a transport agent to become a gas.

- This gas diffuses to a cooler zone (T₁).

- In the cooler zone, the reaction reverses, depositing your purified material as a crystal and releasing the transport agent to repeat the cycle.

The driving force for this entire journey is the temperature gradient—the stable, predictable difference between T₂ and T₁.

This is where most experiments fail.

Many labs treat their furnace as a simple oven—a box that gets hot. But if the temperatures in your hot and cold zones fluctuate even slightly, or if the heat isn't perfectly uniform, the gradient becomes unstable.

- An unstable gradient is like a sputtering engine. The chemical reaction doesn't know whether to move forward or reverse. The transport of material stalls, stutters, or stops completely.

- An imprecise gradient means your growth is uncontrollable. Too steep, and you get a fast, messy deposition of tiny crystals. Too shallow, and the process is too slow to be practical.

This is why your previous fixes failed. Changing the chemistry inside the ampoule is useless if the thermodynamic engine driving it is unreliable. You can have the perfect fuel (chemicals) and a perfect car body (sealed tube), but with a sputtering engine (unstable furnace), you will never reach your destination predictably.

From Simple Heater to Thermodynamic Engine: The KINTEK Furnace Advantage

To achieve repeatable, high-quality crystal growth, you don't need more luck; you need a tool designed with a deep understanding of this fundamental principle. You need to replace the simple "heater" with a precision thermodynamic engine.

This is precisely why KINTEK's tube furnaces are engineered for success in demanding applications like CVT. They are not just ovens; they are instruments built to establish and maintain the pristine thermal conditions required for these delicate processes.

- Precise Multi-Zone Control: Our furnaces create distinct, programmable hot and cold zones, allowing you to define the exact temperature gradient your specific reaction requires for optimal growth.

- Exceptional Temperature Stability: We engineer our systems for minimal temperature fluctuation. This stability ensures the thermodynamic engine runs smoothly and continuously, driving the transport reaction predictably from start to finish.

- Superior Thermal Uniformity: The tubular design, combined with high-quality heating elements and insulation, provides uniform heat around the entire ampoule. This prevents unwanted hot or cold spots that can disrupt the gas diffusion and lead to flawed crystal formation.

A KINTEK furnace directly addresses the root cause of CVT failure because it is built to control the thermodynamics of the system, transforming an unpredictable art into a repeatable science.

New Frontiers: What Predictable Crystal Growth Unlocks for Your Lab

When you are no longer fighting with your equipment, you are free to focus on discovery. Solving the puzzle of reproducibility doesn't just fix a problem; it opens up entirely new possibilities.

With a stable, controllable CVT process, you can now:

- Accelerate R&D: Move from one successful experiment to the next, rapidly synthesizing and testing novel materials without wasting months on troubleshooting.

- Create Higher-Quality Materials: Confidently grow the large, structurally perfect single crystals that are essential for developing next-generation electronics, catalysts, and quantum materials.

- Unlock New Discoveries: Systematically explore the effects of subtle changes in growth parameters, knowing that your results are due to your scientific choices, not equipment error.

- Build a Reputation for Reliability: Produce consistent, high-purity materials that make your research—and any resulting products—more credible and valuable.

Ultimately, mastering your synthesis process allows you to move beyond being a technician and become the pioneering scientist you set out to be.

Your research is too important to be derailed by inconsistent equipment. If you're ready to move past the frustration of failed experiments and unlock the full potential of your materials synthesis, our team of experts is here to help you configure the right thermal solution. We understand the complex interplay between chemistry and thermodynamics that defines your work. Let's discuss the specific challenges of your project and how a precision furnace can become the most reliable part of your discovery process. Contact Our Experts.

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

Related Articles

- The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

- The Controlled Universe: Mastering Matter Inside a 70mm Tube Furnace

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

- Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)