You’ve done everything right. The material is the highest grade, the parts have been meticulously cleaned, and the temperature profile for your heat treatment process is programmed to the tenth of a degree. Yet, when you open the furnace, something is wrong. A subtle tarnish dulls the surface, or worse, the component later fails mechanical testing, proving to be unexpectedly brittle. All that time, effort, and expensive material—wasted.

If this scenario feels painfully familiar, you're not alone.

The Frustrating Cycle of 'Almost Perfect'

Across advanced R&D and manufacturing, from aerospace alloys to medical implants, this is a recurring nightmare. A process that works one day yields subpar results the next. This inconsistency triggers a frustrating cycle of troubleshooting:

- "Is it our cleaning protocol?" You implement a more rigorous, multi-stage cleaning process, adding time and cost, but the random failures persist.

- "Is it the raw material?" You spend weeks validating new suppliers, only to find the problem eventually returns.

- "Is our furnace temperature unstable?" You invest in new controllers and calibration, yet the root issue remains elusive.

This isn't just a technical headache; it's a direct threat to your objectives. Project timelines stretch from weeks into months. Production yields plummet, driving up costs per unit. Most critically, the reliability of your final product is called into question, a risk that is unacceptable in high-stakes applications.

You're chasing ghosts because you're looking in the wrong place. The problem isn't what you're putting into the furnace; it's what's already there.

The Real Culprit: It's Not the Material, It's the Atmosphere

The culprit is invisible, odorless, and all around us: the air.

In our daily lives, air is harmless. But inside a high-temperature furnace, it transforms into an aggressive cocktail of reactive gases. The two primary offenders are oxygen and water vapor.

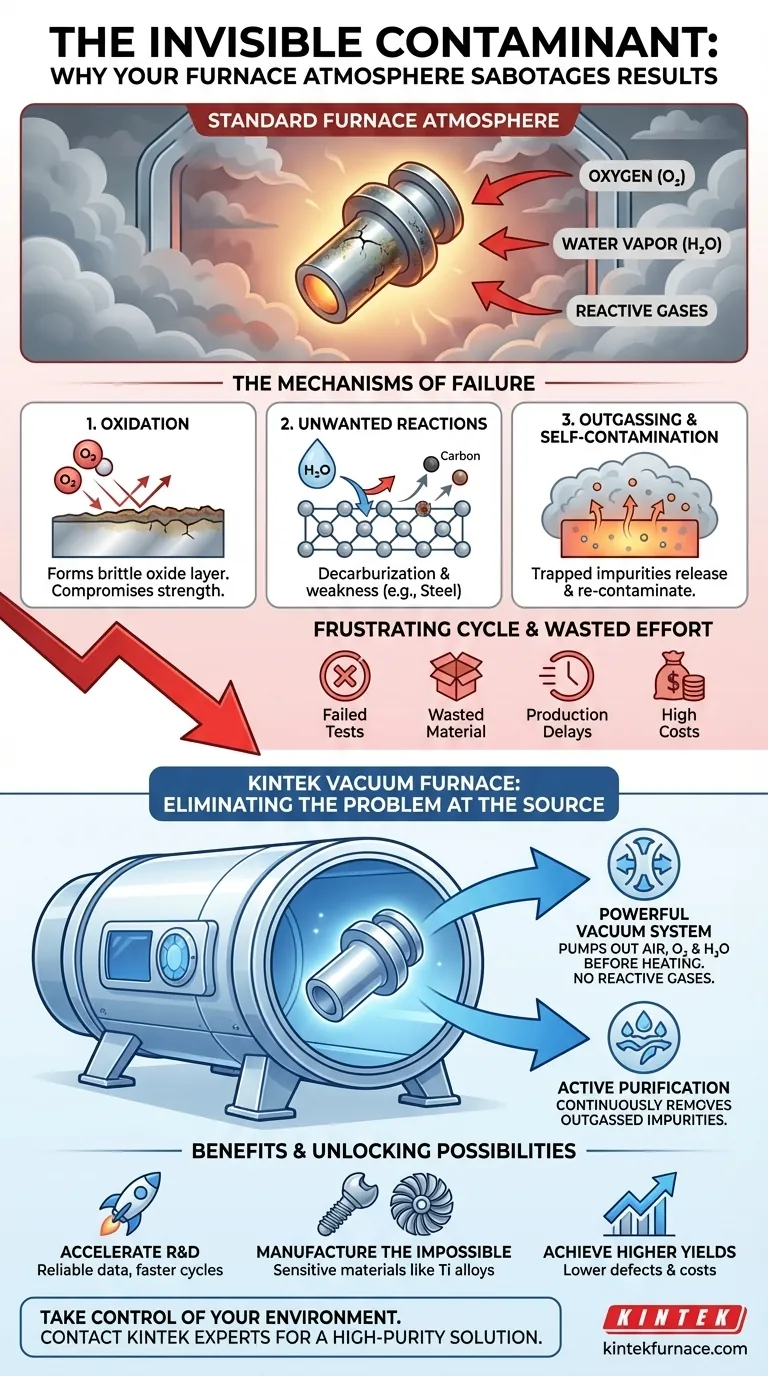

How "Harmless" Air Becomes a Saboteur

At elevated temperatures, materials become chemically reactive. When exposed to the atmosphere inside a standard furnace, a destructive chain reaction begins:

- Oxidation: Oxygen molecules eagerly react with the hot surface of your material, forming a brittle, often discolored oxide layer. This contamination compromises everything from electrical conductivity to mechanical strength.

- Unwanted Reactions: Even trace amounts of moisture (H₂O) can react with certain materials, disrupting their chemical composition. In steel treatment, for example, reactive gases can cause decarburization—a phenomenon where carbon leaches from the surface, making the steel weaker.

- Self-Contamination: As the workpiece heats up, it can release trapped gases and volatile impurities from within its own structure—a process called outgassing. In a sealed atmospheric furnace, these newly released contaminants have nowhere to go. They form a toxic cloud around your part, re-contaminating its surface.

This is why your previous attempts failed. You were treating the symptoms—like a dirty surface—instead of curing the disease: an uncontrolled, reactive processing environment.

Taking Control: How a Vacuum Furnace Eliminates the Problem at its Source

To achieve truly pure, repeatable results, you don't need a better cleaning agent; you need to remove the battlefield itself. You need to eliminate the atmosphere.

This is the fundamental principle behind a vacuum furnace. It is designed not just as a heating device, but as a precision environmental control system. It systematically removes the root cause of contamination.

- It Eliminates the Primary Threat: Before the heating cycle even begins, a powerful vacuum system pumps out the air, removing virtually all the oxygen and moisture. With no reactive gases present, oxidation simply cannot occur. Your parts remain bright and clean.

- It Actively Purifies the Environment: A vacuum furnace doesn't just create a clean slate; it maintains it. The vacuum system runs continuously throughout the process, instantly pulling away any impurities released during outgassing. It actively protects the workpiece from its own emissions.

This is not a workaround; it's a fundamental solution. KINTEK's advanced vacuum furnaces are engineered from the ground up to provide this level of absolute environmental control. They are the purpose-built tools for labs and manufacturers who cannot afford to compromise on material integrity. Our deep customization capability ensures that whether you need an extremely deep vacuum for semiconductor research or a precisely controlled inert gas backfill for a sensitive alloy, the furnace is tailored to your exact process requirements.

Beyond Purity: Unlocking New Possibilities in Material Science

When you eliminate environmental contamination as a variable, everything changes. You move from a state of reactive troubleshooting to one of proactive innovation.

The question is no longer, "Why did this batch fail?" but rather, "What can we achieve next?"

- Accelerate R&D: With reliable and repeatable results, you can trust your data, shorten development cycles, and bring new materials and products to market faster.

- Manufacture the Impossible: You can now confidently work with highly sensitive, next-generation materials—like titanium alloys for medical implants or single-crystal superalloys for turbine blades—that are impossible to process in a standard atmosphere.

- Achieve Higher Yields: By eradicating a major source of defects, you can dramatically increase production yields, lowering costs and improving profitability.

Solving the contamination problem isn't just about getting cleaner parts; it's about unlocking a new level of material performance and creating opportunities that were previously out of reach.

Your work is too important to be compromised by an invisible contaminant. If you're ready to move beyond frustrating inconsistencies and achieve flawless results, our team of experts can help you architect the perfect high-purity heating solution for your application. Contact Our Experts to discuss your specific project and discover how to take complete control of your material's environment.

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

Related Articles

- The Hidden Flaw in Your Heat Treatment: It’s Not the Temperature, It’s the Air

- Your Lab Furnace Is Burning Money. Here's the Hidden Design Flaw (And How to Fix It).

- Beyond Heat: The Art of Control in a Tube Furnace

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- The Controlled Void: How Tube Furnaces Forge the Materials of Tomorrow