Does this sound familiar? You’re running a critical high-temperature process—annealing a new alloy, growing a crystal, or testing a ceramic component. The experiment itself requires precision. But when the monthly utility bill arrives, you’re faced with a number that feels anything but precise. It’s a huge, unpredictable cost, a budget black hole that seems to grow with every ambitious project you launch. You're left wondering if this is simply the unavoidable cost of cutting-edge research.

The Cycle of Frustration: Why Tweaking Settings Isn't Working

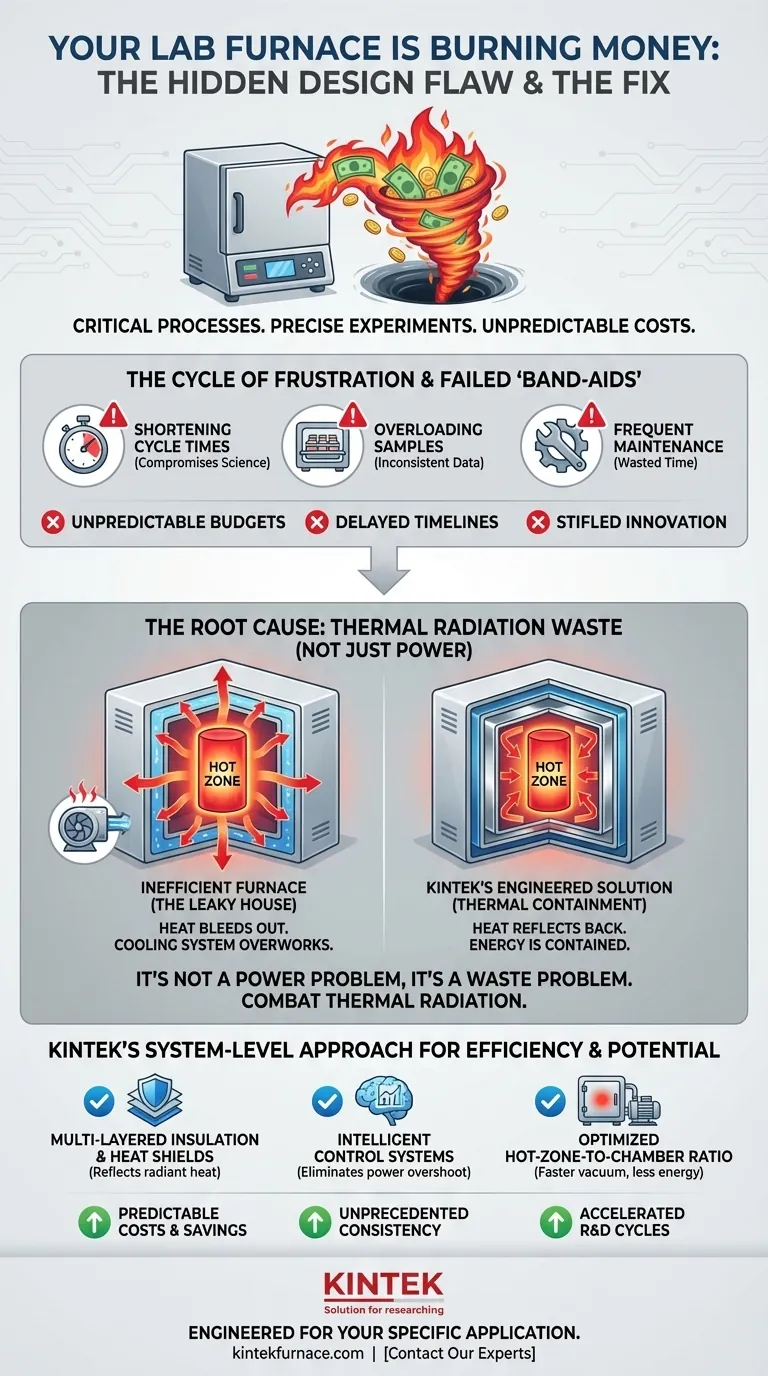

When faced with these escalating energy costs, most labs react in predictable ways. We try to shorten cycle times, hoping to cut down the furnace's runtime. We pack more samples into a single run, risking uneven heating and compromised results. We schedule another round of maintenance, asking technicians to check the seals and pumps for the third time this quarter.

While well-intentioned, these are merely band-aids on a deeper wound. The cycle times are already optimized for the process, so shortening them compromises the science. Overloading the furnace leads to inconsistent data, forcing you to rerun experiments and wasting even more time and energy.

The business consequences are significant and painful:

- Unpredictable Budgets: Project cost forecasting becomes a guessing game, making it difficult to secure funding for future work.

- Delayed Timelines: Rerunning failed experiments due to inconsistent heating pushes project deadlines back.

- Stifled Innovation: Researchers become hesitant to run longer, more complex experiments that could lead to breakthroughs, simply because they are deemed "too expensive" to operate.

You're stuck in a frustrating loop, treating the symptoms without ever addressing the real disease.

The Real Culprit: It's Not About Power, It's About Waste

Here is the turning point in understanding this problem: An expensive-to-run furnace isn't just using a lot of power; it's actively wasting it. The root cause isn't a single faulty component, but a fundamental flaw in its design philosophy.

Think of your furnace like a house in the dead of winter. You can have the most powerful heater on the market, but if the house has thin walls, drafty windows, and poor insulation, that heater will run constantly just to maintain the temperature. The energy isn't being used effectively; it's bleeding out into the cold air.

A poorly designed vacuum furnace is a very expensive, leaky house. Heat escapes through three primary methods: conduction (touch), convection (air movement), and radiation (infrared energy).

- A vacuum virtually eliminates conduction and convection. That’s the easy part.

- The real battle is against thermal radiation.

In an inefficient furnace, massive amounts of radiant heat escape the "hot zone," hitting the water-cooled outer walls. Your cooling system then has to work overtime to dissipate this wasted energy. Your heating elements are fighting a losing battle, constantly pumping in power to replace the heat that is bleeding away.

This is why simply tweaking settings fails. You're just telling the powerful (but inefficient) heater to run for a little less time, while doing nothing to patch the leaks in the walls.

Solving the Leak: How System-Level Design Creates Efficiency

To truly solve the problem, you don't just need a furnace that gets hot. You need a furnace that is intelligently designed to keep the heat where it belongs: on your sample. This requires a holistic, system-level design where every component works in concert to contain thermal energy.

This is precisely where an engineered solution, built on a deep understanding of thermal dynamics, becomes critical. A truly efficient furnace is an integrated system.

KINTEK: Engineering for Thermal Containment, Not Just Heat

At KINTEK, we don't just build hot boxes; we engineer complete thermal systems. Our furnaces are designed from the ground up to address the root cause of energy waste.

-

Targeting Radiation Waste: Instead of basic insulation, we use multi-layered insulation packages with materials like graphite felt and reflective metallic heat shields. These act like a mirror, reflecting radiant heat back toward the workload instead of letting it escape. This is like upgrading from a drafty wall to a modern, vacuum-insulated one.

-

Eliminating Power Overshoot: Our intelligent control systems act like a sophisticated cruise control for temperature. They deliver the precise amount of power needed to reach and hold the target temperature without the wasteful "overshooting" common in simpler systems.

-

Optimizing the Entire System: We carefully calculate the hot-zone-to-chamber ratio. A tighter, more optimized volume allows the vacuum pumps to work less, reaching the target vacuum faster and consuming less energy from the start.

Because every thermal process has unique demands, our deep customization capability is key. We don't offer a one-size-fits-all solution that is mediocre for everyone. We engineer the entire system—from insulation type to control logic—to be maximally efficient for your specific application.

Beyond Savings: Unlocking New Research Potential

When you stop constantly battling an inefficient, energy-draining furnace, something remarkable happens. The conversation shifts from "How can we afford this?" to "What can we achieve next?"

With predictable operational costs and a thermally stable environment, you unlock new capabilities:

- Run Longer, More Ambitious Experiments: Tackle complex, multi-day processes without the fear of a crippling energy bill.

- Achieve Unprecedented Consistency: Stable, uniform heating means more reliable data, fewer failed runs, and faster progress.

- Accelerate R&D Cycles: Trusting your equipment allows you to focus on the science, not on troubleshooting hardware.

Your research is too important to be held back by inefficient tools. It's time to stop feeding a budget black hole and invest in a solution designed for performance and precision. Let's discuss how a furnace engineered specifically for your process can not only lower your operational costs but also accelerate your next breakthrough.

Contact Our Experts to build the right solution for your lab.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

Related Articles

- Mastering the Void: How Tube Furnaces Forge the Atoms of Innovation

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- The Hidden Cause of Uneven Heating in Your Furnace (And How to Fix It)

- Clarity Under Fire: The Psychological Case for Quartz Tube Furnaces