The Cycle is Finished. The Sample is Ruined. What Went Wrong?

You’ve spent days, maybe weeks, preparing a critical sample. You carefully place it in the vacuum furnace, program the precise thermal cycle, and wait. Hours later, the cycle completes. You open the chamber with anticipation, only to find the result is a failure. One side of the material is scorched, the other under-processed. The sample is warped, the data is useless, and your project is set back.

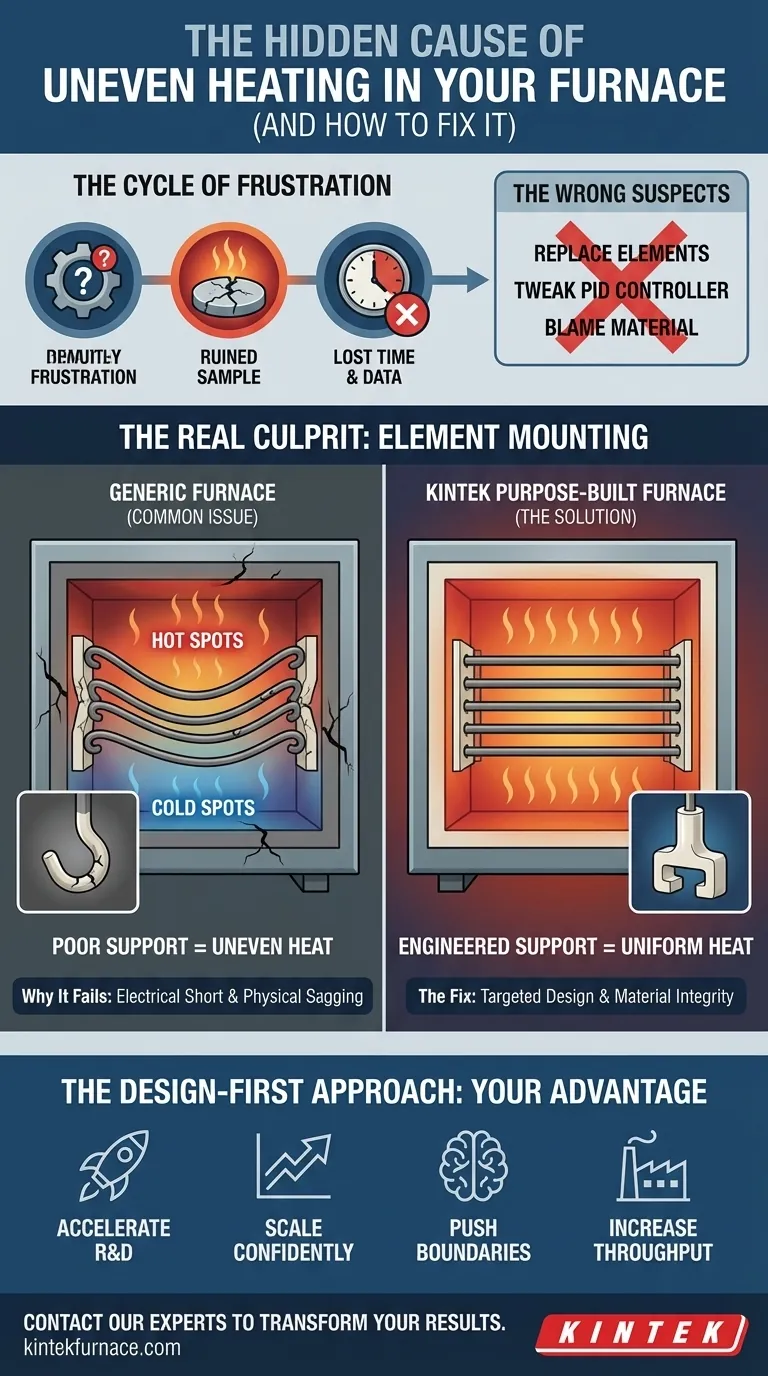

It’s a deeply frustrating scenario, one that plays out in R&D labs and production facilities far too often. The immediate suspect? A faulty heating element or a miscalibrated controller. But what if the true culprit is something you can’t even see?

The Familiar Cycle of Troubleshooting: Why 'Common Fixes' Fail

When faced with inconsistent heating, most teams follow a predictable script. They might:

- Replace the heating elements: Assuming an element is "burning out," they install a new one, only to see the same problem reappear after a few cycles.

- Tweak the PID controller: They spend hours adjusting ramp rates and hold times, trying to program their way around a fundamental hardware problem.

- Blame the material: They question the sample itself, leading to another round of costly and time-consuming material preparation.

These efforts rarely solve the problem because they are symptoms, not the cause. This cycle of trial-and-error doesn't just waste time and materials; it has serious business consequences. Project timelines slip, R&D costs balloon, and a lack of process reliability makes it impossible to confidently scale a new material or component from the lab to production. You're stuck firefighting equipment instead of driving innovation.

It’s Not the Heat, It’s the Holder: The Critical Role of Element Mounting

The turning point comes when you stop looking at the heating element as a simple filament and start seeing it as part of a complex electromechanical system. The real problem often lies in the engineering of its mounting.

In the extreme environment of a high-temperature vacuum furnace, holding a heating element in its precise position is a profound engineering challenge. The mounting system has two non-negotiable jobs:

1. Guarantee Electrical Isolation

A heating element is essentially a controlled resistor carrying a powerful electrical current. The mounting hardware—typically made of specialized ceramics or quartz—acts as a high-performance insulator. If this insulator fails, cracks, or is improperly designed, the element can make contact with the furnace body, causing a catastrophic short-circuit that can destroy the element and damage the furnace.

2. Ensure Physical Stability at Extreme Temperatures

At temperatures exceeding 1500°C, materials behave differently. Metals can soften, sag, and deform under their own weight. The mounting system—a series of carefully placed hooks, hangers, and supports—must hold the element in its exact engineered position, cycle after cycle. If a support fails and an element sags, the carefully designed heating geometry is ruined. This creates the exact "hot spots" and "cold spots" that destroy your samples.

This is why simply replacing an element often fails. You are placing a brand-new component into a compromised or poorly designed support system, all but guaranteeing it will suffer the same fate as its predecessor.

Engineering Stability: A Design-First Approach to Perfect Heating

To permanently solve the root cause of thermal instability, you need a furnace that wasn't just built, but designed with these principles at its core. It requires a system where the heating element configuration is treated as an integral part of the solution, not an afterthought.

This is the philosophy behind KINTEK’s advanced furnace solutions. We understand that achieving uniform, repeatable heating is not about using more powerful elements; it's about orchestrating the heat with precision.

- Targeted Mounting Design: Instead of a one-size-fits-all approach, we leverage our deep customization capabilities to engineer the element mounting configuration—be it wall-mounted, roof-suspended, or floor-placed—to deliver the most uniform thermal profile for your specific workload. The size, shape, and mass of your sample directly inform our design.

- Material Integrity: We utilize only high-purity ceramic and refractory hardware for our mounting systems. These materials provide superior electrical insulation and mechanical strength at the highest temperatures, ensuring they won't degrade, outgas, or compromise the integrity of your vacuum environment.

A KINTEK furnace isn't just a box that gets hot. It is a purpose-built thermal processing system designed from the ground up to ensure every component, especially the often-overlooked mounting system, contributes to stable, reliable, and uniform performance.

From Reliability to Breakthroughs: What’s Possible with Perfect Heat Control

When you eliminate inconsistent heating, you do more than just prevent failed experiments. You unlock new potential for your entire operation. With a furnace that delivers predictable and uniform results every time, you can:

- Accelerate R&D: Stop wasting time troubleshooting equipment and dedicate your team’s full expertise to material science and innovation.

- Scale with Confidence: Develop processes in the lab with the certainty that they can be replicated reliably in a production environment.

- Push the Boundaries: Explore more complex, longer-duration thermal cycles for next-generation materials, knowing your equipment is stable enough to handle the challenge.

- Increase Throughput: Dramatically reduce sample wastage and equipment downtime, getting more valuable work done in less time.

Your thermal process is unique, and a generic furnace often yields generic—and frustrating—results. It's time to address the root cause of your heating issues. Our team of experts can help you analyze your application and design a system engineered for the specific challenges you face. Contact Our Experts to discuss how a purpose-built furnace can transform your results from inconsistent to infallible.

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

Related Articles

- Mastering the Void: How Tube Furnaces Engineer Predictable Outcomes

- Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

- Mastering the Micro-Environment: The Art and Science of the Laboratory Tube Furnace

- Beyond Heat: The Physics of Control in a Tube Furnace

- The Controlled Universe: Why Tube Furnaces Prioritize Precision Over Scale