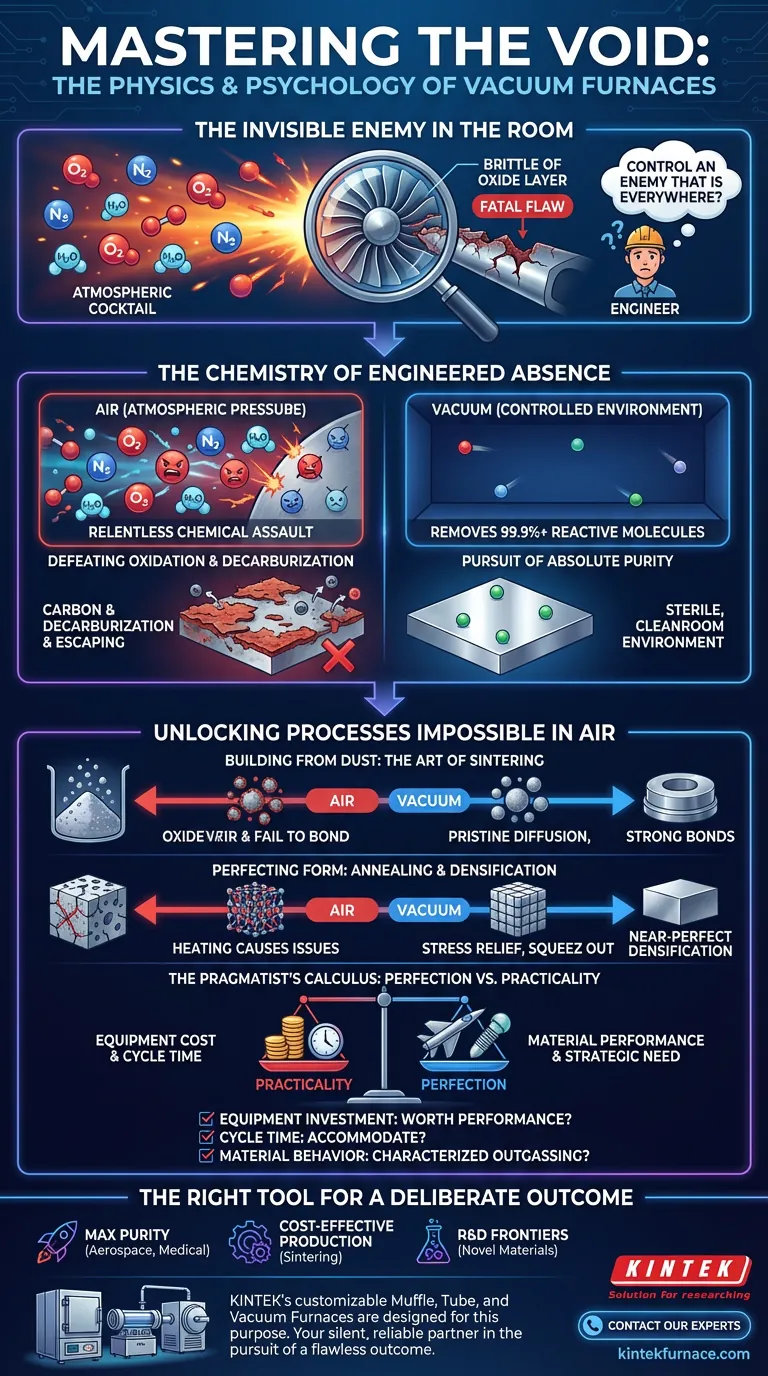

The Invisible Enemy in the Room

An aerospace engineer inspects a newly forged turbine blade. To the naked eye, it's perfect. But under a microscope, a microscopic network of oxide inclusions reveals a fatal flaw—a weakness initiated by an invisible saboteur.

The enemy? The air itself.

We spend our lives immersed in the atmosphere, rarely considering it an active chemical agent. But in the world of high-performance materials, the oxygen, nitrogen, and water vapor we breathe become aggressive contaminants at high temperatures. This introduces a profound psychological challenge for engineers and scientists: how do you control an enemy that is everywhere and nowhere at once?

The answer is not to fight it, but to remove the battlefield entirely. This is the philosophy behind the vacuum furnace. It’s not about creating emptiness; it’s about establishing absolute control.

The Chemistry of Engineered Absence

A vacuum is not a void. It is a highly controlled, engineered environment, deliberately stripped of reactive molecules.

At sea level, every square inch of a material is bombarded by trillions of gas molecules. At room temperature, this is mostly benign. But add the energy of a heat treatment process, and this gentle atmospheric pressure transforms into a relentless chemical assault.

The core function of a vacuum furnace is to halt this assault before it begins.

Defeating Oxidation and Decarburization

The most obvious attacker is oxygen. At high temperatures, it aggressively bonds with most metals, forming a brittle, flaky oxide layer. This is oxidation. For high-carbon steels, it also strips carbon from the surface, a process called decarburization that softens the material precisely where it needs to be hardest.

A vacuum environment removes over 99.9% of these oxygen molecules. It doesn’t just slow the reaction; it prevents it from ever happening, preserving the material’s intrinsic surface integrity and chemical composition.

The Pursuit of Absolute Purity

Air, however, is not just oxygen. It’s a cocktail of gases. Nitrogen can form unwanted nitrides. Water vapor can introduce hydrogen, leading to embrittlement.

These subtle forms of contamination can alter a material’s fundamental properties in unpredictable ways. A vacuum furnace removes this uncertainty, ensuring that the only elements present are the ones you intentionally put there. It’s the closest thing to a sterile, cleanroom environment for metallurgy.

Unlocking Processes Impossible in Air

By removing the constraints of atmospheric pressure and chemistry, vacuum furnaces enable thermal processes that would otherwise be physically impossible.

Building from Dust: The Art of Sintering

Sintering is the delicate art of fusing powdered materials into a solid, dense part without melting them. It’s how many high-strength ceramics and complex metal components are made.

In open air, the immense surface area of the powder would lead to catastrophic oxidation long before the particles could bond. A vacuum provides the pristine, high-temperature stage required for atoms to diffuse across particle boundaries, creating a strong, unified component.

Perfecting Form: Annealing and Densification

A vacuum also fundamentally alters a material's physical behavior. Processes like annealing—which refines a material’s crystal structure to relieve stress and improve ductility—are far more effective without atmospheric interference.

Furthermore, under vacuum, materials can be heated to higher temperatures before they begin to vaporize. This allows processes like vacuum hot-pressing to squeeze out the final pockets of porosity in a component, achieving near-perfect densification and superior mechanical strength.

The Pragmatist's Calculus: Perfection vs. Practicality

A vacuum is a powerful tool, but its adoption requires a clear-eyed assessment of its trade-offs. The decision is a balance between the ideal and the practical.

| Consideration | The Engineering Reality | The Strategic Question |

|---|---|---|

| Equipment & Cost | Vacuum systems are a significant capital and operational investment. | Is the required material performance worth the investment? |

| Cycle Time | Pumping a chamber down to vacuum takes time, slowing throughput. | Can our production schedule accommodate the additional process time? |

| Material Behavior | Outgassing can release trapped gases, contaminating the process. | Have we characterized our material's behavior under vacuum? |

This calculus forces a deliberate choice. You don’t use a vacuum furnace by default; you use it when the cost of failure is unacceptably high and the need for control is non-negotiable.

The Right Tool for a Deliberate Outcome

Ultimately, the choice of a processing environment comes down to intent.

- For maximum purity and performance in aerospace, medical, or semiconductor applications, a vacuum is the only option.

- For cost-effective production of complex parts, vacuum sintering offers a path to creating strong, near-net-shape components with minimal waste.

- For the research and development of novel materials, a vacuum provides the pure, controlled environment necessary to explore the frontiers of science.

This level of control is not accidental; it is the product of precisely engineered systems. For researchers and manufacturers navigating these trade-offs, the goal is to find a system that matches their specific ambition. Solutions like KINTEK’s customizable Muffle, Tube, and Vacuum Furnaces are designed for this purpose. Whether pioneering new materials with a CVD system or ensuring metallurgical perfection, the right furnace becomes a silent, reliable partner in the pursuit of a flawless outcome.

To achieve this level of environmental mastery, you need more than equipment; you need expertise. If you're ready to eliminate the unseen variables in your work, Contact Our Experts.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- Mastering the Void: How Custom Vacuum Furnaces Forge the Future of Materials

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale