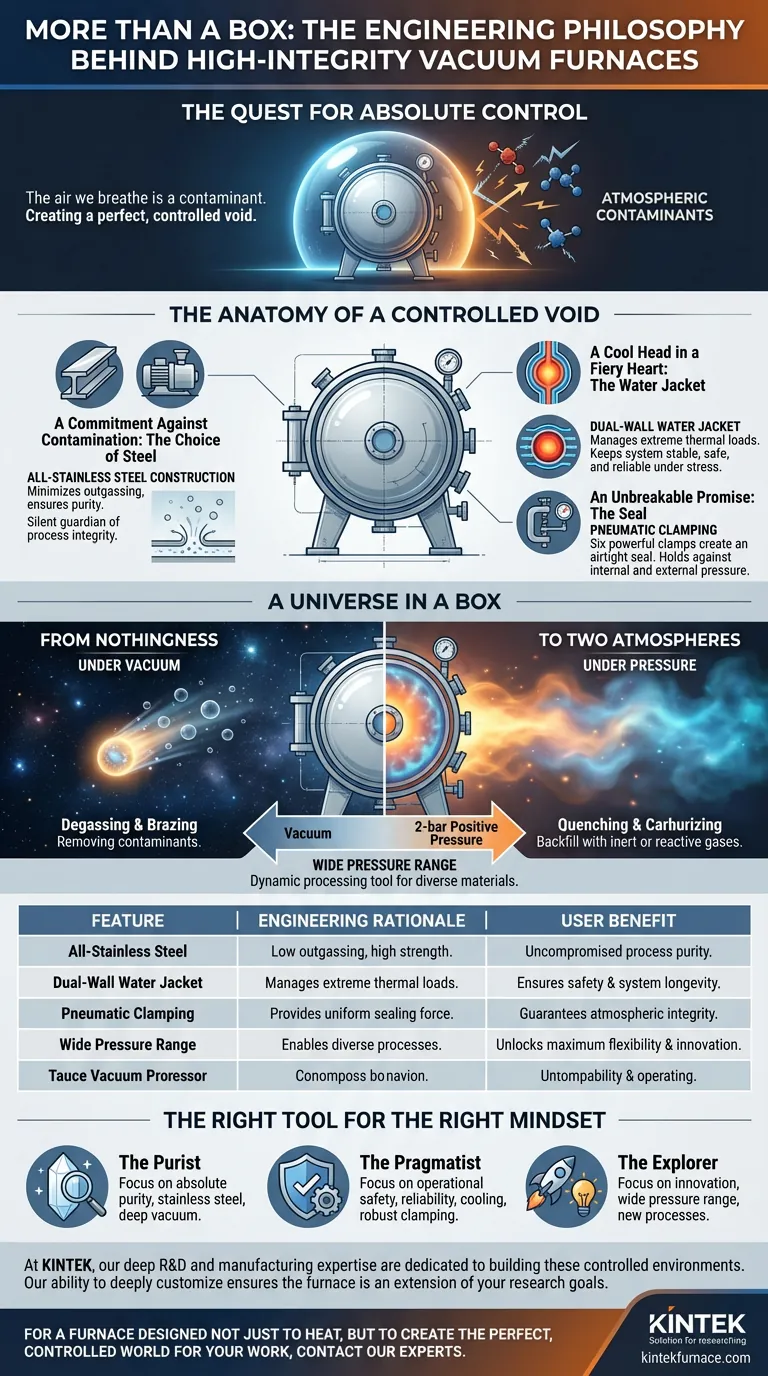

The Quest for Absolute Control

At its core, advanced materials science is a quest for control. It's a battle against the random, chaotic influence of the everyday world—specifically, the atmosphere.

The air we breathe is a contaminant. The slightest trace of oxygen or nitrogen can ruin a sensitive metallurgical process, rendering a high-value component useless. To create the materials of the future, we first need to create a perfect, controlled void.

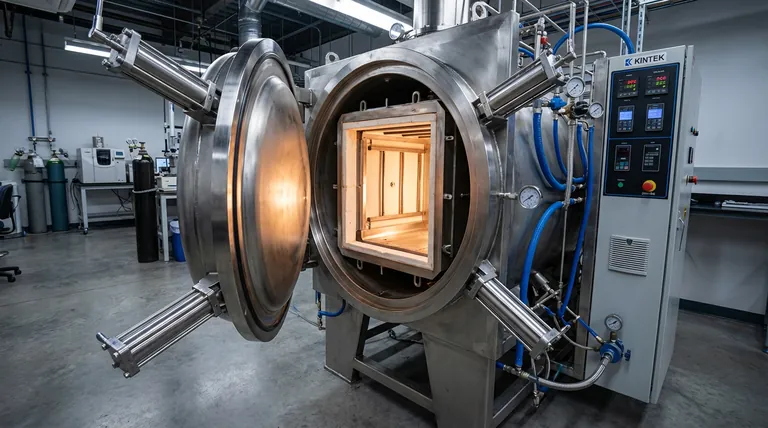

This is the profound responsibility of the vacuum furnace chamber. It's not merely a stainless steel box; it's a self-contained universe, engineered to defy the outside world.

The Anatomy of a Controlled Void

The design of a furnace chamber is a series of deliberate choices, each one a defense against a specific physical threat. Understanding these choices reveals the philosophy behind the machine.

A Commitment Against Contamination: The Choice of Steel

The chamber is built entirely of stainless steel. This isn't an arbitrary choice based on strength alone. It’s a commitment to purity.

In the world of high vacuum, the material of the chamber itself can become the enemy. Lesser materials contain trapped gases that are slowly released under vacuum—a phenomenon called outgassing. This process poisons the pristine environment you're trying to create.

Stainless steel, with its dense structure, minimizes outgassing. It is the silent, steadfast guardian of the process's integrity.

A Cool Head in a Fiery Heart: The Water Jacket

Inside the chamber, the "hot zone" can reach temperatures that would easily warp and weaken the structure. The furnace's heart is a place of immense thermal energy.

To contain this, the chamber is built with a dual-wall, water-jacketed design. A constant flow of cool water circulates through the walls and door, acting as the system's calm, rational mind.

This thermal management isn't just for safety; it's for stability. It keeps the steel strong, the vacuum seals intact, and the entire system predictable and reliable under extreme stress. It's the engineering equivalent of keeping a cool head under pressure.

An Unbreakable Promise: The Seal

Creating a vacuum means the entire force of Earth's atmosphere—about 14.7 pounds per square inch—is trying to crush the chamber. When operating at positive pressure, the chamber is trying to burst.

The door is secured by six powerful pneumatic clamps. This isn't just a latch; it's a physical promise. The immense, evenly distributed force they apply creates an airtight seal that holds against both internal and external pressure. It is the unwavering line between the controlled world inside and the chaos outside.

A Universe in a Box

With its integrity established, the chamber becomes a vessel for creation, capable of hosting a wide range of precisely controlled physical processes.

From Nothingness to Two Atmospheres

The ability to operate from a full vacuum up to a 2-bar positive pressure transforms the furnace from a simple oven into a dynamic processing tool.

- Under Vacuum: You can perform processes like degassing and brazing, where removing atmospheric contaminants is the primary goal.

- Under Pressure: You can backfill the chamber with inert gases like argon for quenching or introduce reactive gases for processes like carburizing.

This range gives researchers and engineers the flexibility to create the exact atmospheric "universe" their material requires.

| Feature | Engineering Rationale | User Benefit |

|---|---|---|

| All-Stainless Steel | Low outgassing, high strength, corrosion resistance. | Uncompromised process purity. |

| Dual-Wall Water Jacket | Manages extreme thermal loads on all surfaces. | Ensures operator safety and system longevity. |

| Pneumatic Clamping | Provides immense, uniform sealing force. | Guarantees atmospheric integrity under any condition. |

| Wide Pressure Range | Enables diverse processes from degassing to quenching. | Unlocks maximum process flexibility and innovation. |

The Right Tool for the Right Mindset

Choosing a vacuum furnace is about matching the engineering to your specific scientific or industrial goal. It comes down to what you value most.

- The Purist: If your obsession is absolute material purity, your focus will be on the stainless steel construction and the system's ability to achieve a deep, clean vacuum.

- The Pragmatist: If operational safety and long-term reliability are your non-negotiables, the comprehensive water-cooling system and robust clamping mechanism are the most critical features.

- The Explorer: If you need the freedom to innovate and push boundaries, the wide operational pressure range is your key to unlocking new processes.

Achieving this level of specialized performance isn’t about finding a one-size-fits-all solution. It's about engineering a system with a specific intent.

At KINTEK, our deep R&D and manufacturing expertise are dedicated to building these controlled environments. We understand that whether you're working with a Tube Furnace, a CVD system, or a high-vacuum chamber, the goal is always precise control. Our ability to deeply customize each system ensures the furnace isn't just a piece of equipment, but a true extension of your research goals.

For a furnace designed not just to heat, but to create the perfect, controlled world for your work, Contact Our Experts.

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

Related Articles

- The Architecture of Nothing: Inside the Controlled Universe of a Vacuum Furnace

- The Cascading Logic of Safety: Rethinking the Modern Vacuum Furnace

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- The Hidden Flaw in Your Heat Treatment: It’s Not the Temperature, It’s the Air