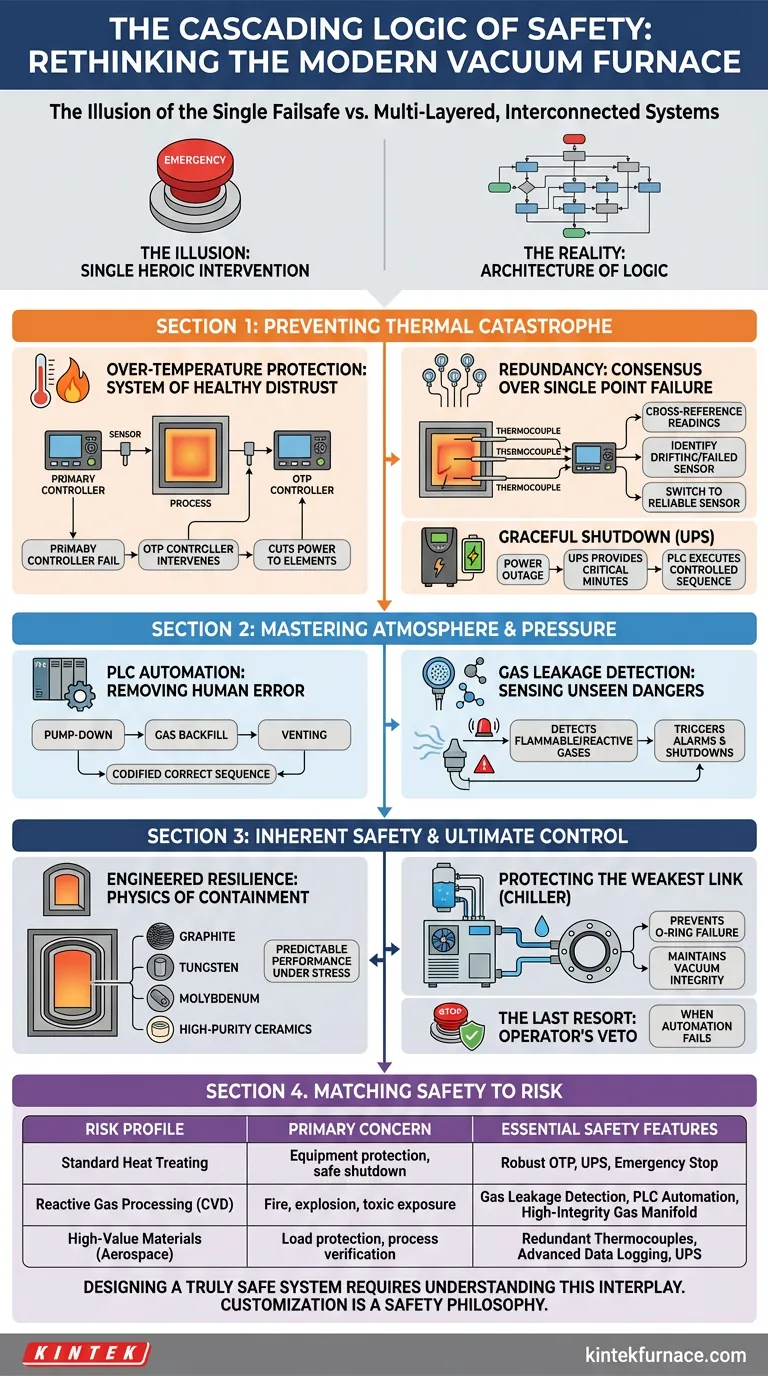

The Illusion of the Single Failsafe

We have a cognitive bias for simple solutions. In a high-temperature lab, we see the big red emergency stop button and feel a sense of security. We see it as the safety feature.

This is a dangerous illusion.

A modern vacuum furnace doesn't derive its safety from a single button. Its security is a multi-layered, interconnected system—an architecture of logic designed to anticipate and mitigate failure at every level. It's less about a single heroic intervention and more about a quiet, vigilant system that prevents the crisis from ever happening.

True safety isn't a feature; it's a design philosophy.

The First Line of Defense: Preventing Thermal Catastrophe

The most visceral fear in high-temperature work is a thermal runaway. This is where the primary safety systems focus their attention, acting as unsleeping guardians against the system's own power.

Over-Temperature Protection: A System of Healthy Distrust

The most critical safety layer is the over-temperature protection (OTP). It’s not just an alert; it's a completely separate controller with its own sensor.

Its sole purpose is to watch the main process controller and assume it might fail. If the primary system allows the temperature to exceed a critical threshold, the OTP bypasses it entirely and cuts power to the heating elements. It's a system built on engineered mistrust, the ultimate check and balance against software glitches or primary sensor failure.

The Wisdom of Redundancy: Why One Sensor is None

Relying on a single thermocouple is like navigating a storm with a single compass. If it's wrong, you'll never know until it's too late.

High-reliability systems employ multiple thermocouples. This isn't just about having a backup; it's about creating a consensus. The control system can cross-reference readings, identify a drifting or failed sensor, and either alert the operator or switch to a reliable sensor. This transforms a potential point of catastrophic failure into a simple maintenance notification.

Taming Chaos: The Graceful Shutdown

A sudden power outage during a high-temperature cycle is pure chaos. Pumps stop, valves are stuck in position, and hot components are left without cooling. The result can be a damaged furnace, a ruined payload, or worse.

An Uninterruptible Power Supply (UPS) isn't just for keeping the lights on. Its true purpose is to provide a few crucial minutes of power so the Programmable Logic Controller (PLC) can execute a controlled, graceful shutdown sequence. It methodically closes valves, vents chambers, and maintains cooling just long enough to bring the system to a safe, stable state. It imposes order on a potentially chaotic event.

Mastering the Invisible: Atmosphere and Pressure Integrity

What you can't see is often the most dangerous. A furnace's internal atmosphere—whether a deep vacuum or a specific process gas—is fundamental to safety.

Automating Complexity, Removing Human Error

Complex processes like pump-downs, gas backfills, and venting require precise, repeatable sequences. Doing this manually, especially across multiple shifts or operators, introduces the highest-risk variable: human error.

A PLC automates these critical steps. By codifying the correct sequence, it eliminates guesswork and ensures the process is executed perfectly every time. This is the same principle behind a pilot's checklist; it offloads complex memory tasks to a reliable system, freeing the operator to focus on monitoring the big picture.

Sensing the Unseen Dangers

When working with flammable or reactive gases like hydrogen, the human senses are useless for detecting a leak until it's an immediate disaster.

A dedicated gas leakage detection system acts as a superhuman sense. It constantly sniffs the air for molecules that don't belong, triggering alarms and initiating shutdowns long before a dangerous concentration can accumulate.

The Foundation: Inherent Safety and Ultimate Control

Beyond active electronics, safety is embedded in the very physics and structure of the furnace.

Engineered Resilience: The Physics of Containment

A furnace chamber is more than a box. It's a containment vessel. The choice of materials—graphite, tungsten, molybdenum, or high-purity ceramics—is a critical safety decision.

These materials are selected for their predictable performance under extreme thermal and chemical stress. At KINTEK, our deep R&D and manufacturing expertise means we don't just build furnaces; we engineer containment systems. Whether it's a Tube Furnace for controlled atmosphere or a complex CVD system, the material science is the bedrock of its safety.

Protecting the Weakest Link

A system is only as strong as its most vulnerable component. In a vacuum furnace, this is often a simple silicone O-ring. If it overheats and fails, vacuum integrity is lost instantly.

This is why a component like a recirculating chiller is a crucial safety feature. By protecting the seals, it protects the entire system from a sudden, cascading failure. It's a perfect example of systems thinking.

The Last Resort: The Operator's Final Veto

Despite all the automation and redundancy, no system can predict every possibility. The emergency stop remains essential.

But its role should be reframed. It is not the first line of defense. It is the absolute last resort—the operator's final, irrevocable veto when all other automated systems have failed to address an unforeseen danger.

The Psychology of Specification: Matching Safety to Risk

Not every furnace needs every safety feature. The right choice is a calculated decision based on the cost and probability of failure.

| Risk Profile | Primary Concern | Essential Safety Features |

|---|---|---|

| Standard Heat Treating | Equipment protection, safe shutdown | Robust OTP, UPS, Emergency Stop |

| Reactive Gas Processing (CVD) | Fire, explosion, toxic exposure | Gas Leakage Detection, PLC Automation, High-Integrity Gas Manifold |

| High-Value Materials (Aerospace) | Load protection, process verification | Redundant Thermocouples, Advanced Data Logging, UPS |

This is where customization becomes a safety philosophy. A one-size-fits-all furnace is a compromise. The ability to specify the right safety systems for your unique application—be it a Muffle, Rotary, or a fully custom Vacuum Furnace—is the most logical way to manage risk. It’s about building the system you actually need.

Designing a truly safe system requires understanding this interplay between automation, material science, and operational risk. Contact Our Experts to build a furnace solution tailored to your specific safety and process needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

Related Articles

- The Alchemy of the Void: How Vacuum Furnace Components Engineer Material Perfection

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace

- The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny

- The Unseen Advantage: How Vacuum Furnaces Forge Metallurgical Perfection