The Invisible Enemy

At thousands of degrees, metal becomes malleable, its crystalline structure ready to be transformed. But at these temperatures, its greatest enemy is not the heat itself. It’s the air we breathe.

Oxygen, so vital to life, becomes a vicious contaminant, creating oxides that compromise the integrity and surface finish of a material.

To achieve metallurgical perfection, you must first do the impossible: create a perfect nothing. This is the quiet, profound purpose of a vacuum furnace. It’s not a hot box; it’s an engineered universe, meticulously designed to control the fundamental forces acting on a material.

The Anatomy of a Controlled World

A vacuum furnace is a system of systems, an orchestra where each instrument must play its part flawlessly. Understanding its architecture is understanding the psychology of control—the relentless pursuit of a predictable, repeatable outcome.

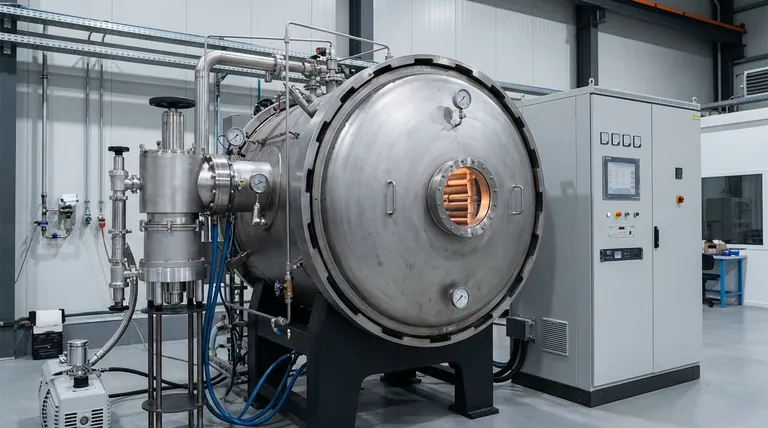

The Vessel: A Fortress Against the Atmosphere

The first component is the most elemental: a boundary. The furnace chamber is a double-walled, water-cooled steel fortress. Its only job is to provide an uncompromising, leak-proof seal against the outside world.

The water circulating between its walls is a quiet testament to the violence within. While the interior rages at temperatures that can melt steel, the exterior remains cool and safe. It's a stark physical barrier separating the chaotic, oxygen-rich atmosphere from the controlled void inside.

The Hot Zone: Forging Heat in an Emptiness

Inside the chamber lies the heart of the furnace: the hot zone. This is where heating elements and insulation conspire to generate and contain immense thermal energy.

The choice of heating element is a philosophical one.

- Graphite is a high-temperature workhorse, capable of reaching over 2200°C. It’s robust and cost-effective. But it carries a risk—the potential for carbon to become a contaminant in highly sensitive alloys.

- Molybdenum and Tungsten create an all-metal hot zone. This is the choice for absolute purity, essential for medical or aerospace components where even a trace of carbon is unacceptable. It’s cleaner, but often more expensive and complex.

Surrounding these elements, layers of graphite felt or ceramic fiber insulation act as mirrors, reflecting thermal energy back onto the workload, ensuring efficiency and temperature uniformity.

The Vacuum System: The Art of Removing Everything

This is what makes a vacuum furnace unique. The vacuum system is an invisible artist, sculpting an environment of near-perfect emptiness.

It doesn’t happen at once. A mechanical "roughing" pump does the heavy lifting, removing over 99% of the air. Then, a more sophisticated diffusion or molecular pump takes over, painstakingly capturing stray molecules to achieve the deep vacuum required for pristine processing.

This staged approach is a journey deeper and deeper into purity, removing the atmospheric variables that lead to unpredictable results.

The Quench: Freezing a Moment in Time

After a material has soaked at its target temperature, its newly arranged atomic structure is fragile. To make it permanent, it must be cooled with incredible speed and control. This is the quench.

The furnace is rapidly backfilled with an inert gas like nitrogen or argon. A powerful fan then blasts this gas through the hot zone and over a water-cooled heat exchanger, pulling heat from the workload in a uniform, controlled storm.

The quench is the final, critical act. It’s what locks in the hardness, strength, and other desired properties. It freezes a perfect metallurgical moment in time.

The Conductor: An Orchestra of Precision

Overseeing this entire process is the control system, typically a PLC (Programmable Logic Controller). It is the silent conductor.

Using thermocouples and vacuum gauges as its senses, it executes a pre-programmed recipe with inhuman precision. It manages heating rates, soak times, vacuum levels, and quenching protocols, ensuring that every cycle is an exact replica of the one before it.

This system replaces human guesswork with digital certainty, which is the ultimate goal of advanced manufacturing.

Every Design is a Deliberate Choice

Building or choosing a vacuum furnace is an exercise in navigating trade-offs. There is no single "best" design, only the one best suited for a specific mission.

- Purity vs. Throughput: A system built for the deepest vacuum takes longer to pump down. A furnace with a massive gas quenching system can cool parts faster, increasing output. You must decide which variable is more critical.

- Cleanliness vs. Cost: An all-metal hot zone offers the cleanest possible environment but comes at a premium. A graphite hot zone is a powerful and economical choice for processes where carbon isn't a concern.

- Application-Specific Design: Brazing high-strength alloys requires excellent temperature uniformity and a clean vacuum. Hardening tool steel demands a powerful, rapid quench. Processing medical-grade titanium demands an immaculate, all-metal environment to prevent any contamination.

The components aren't just parts; they are the physical embodiment of your process priorities. Understanding this allows you to look past a spec sheet and see the furnace's true capability.

At KINTEK, we don't just assemble components; we engineer integrated systems around your specific metallurgical goals. Our deep R&D and manufacturing expertise allows us to customize everything from Muffle and Tube furnaces to complex CVD and Vacuum systems, ensuring the architecture of your furnace perfectly matches the needs of your application.

If you are ready to move from simply heating materials to truly controlling their outcomes, we can help you navigate the choices that matter. Contact Our Experts

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- The Physics of Absence: How Vacuum Furnaces Defy the Limits of Heat

- Gravity as an Ally: The Counterintuitive Genius of Vertical Vacuum Furnaces

- The Physics of Flawless Production: Why Continuous Vacuum Furnaces Redefine Quality at Scale

- The Tyranny of Air: How Vacuum Furnaces Forge Perfection by Removing Everything

- The Physics of Perfection: Deconstructing Temperature Control in a Vacuum Furnace