You’ve done everything by the book. Your material is flawless, your temperature profile is programmed to the decimal, and your process runs exactly as planned. The part emerges from the furnace looking perfect. But during testing, it fails. The surface that should be hard is soft. The joint that should be strong is brittle. The properties from this batch don't match the last. You check your equipment and rerun the experiment, but the results remain frustratingly unpredictable, costing you valuable time, materials, and confidence.

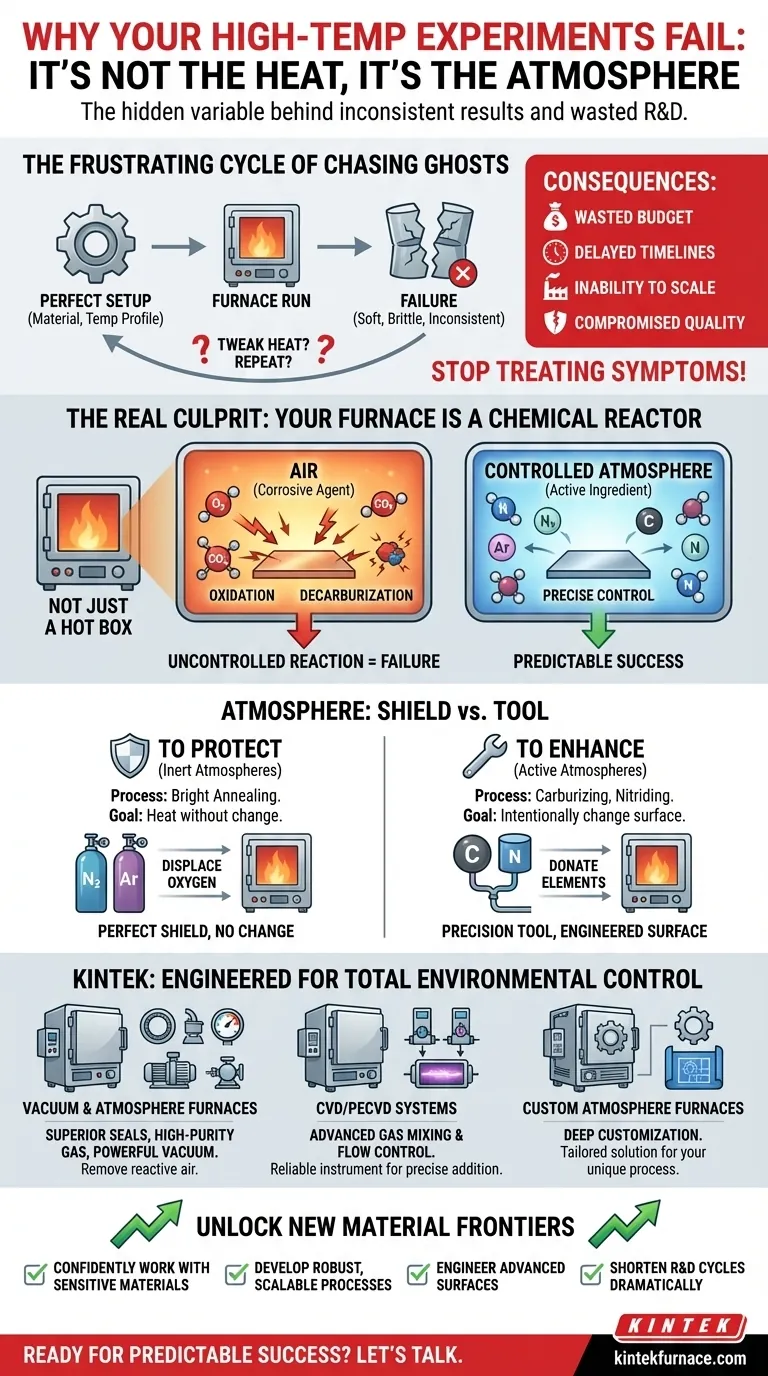

The Frustrating Cycle of Chasing Ghosts

This scenario is a costly reality in countless R&D labs and production facilities. When faced with inconsistent results, the natural instinct is to blame the most obvious variable: the heat. Engineers and researchers will spend weeks tweaking temperature ramp rates, adjusting soak times, and recalibrating thermocouples, assuming the thermal profile is at fault.

These efforts, while well-intentioned, are often a hunt for a ghost. The team is treating the symptoms, not the underlying disease. This leads to a cascade of negative business consequences:

- Wasted R&D Budgets: Precious materials and man-hours are consumed by repeating failed experiments.

- Delayed Timelines: Projects stall, pushing back product launches and jeopardizing contracts.

- Inability to Scale: A process that works "sometimes" in the lab can never be reliably scaled to production, killing innovation before it starts.

- Compromised Quality: For finished products, inconsistent surface properties can lead to catastrophic field failures and damage a company's reputation.

The team is stuck in a loop because they are operating under a fundamental misconception about what a furnace actually does.

The Real Culprit: Your Furnace Isn't Just a Hot Box

The breakthrough comes when you realize that a high-temperature furnace is not simply an oven for making things hot. It is a chemical reactor. At elevated temperatures, the materials you work with become incredibly reactive. The environment surrounding your sample is not a passive space; it is an active chemical ingredient that dictates the final outcome.

The air we breathe, normally harmless, becomes a highly corrosive agent at 800°C, aggressively oxidizing and ruining sensitive materials. Carbon, the key to hardness in steel, can literally be stripped from the surface by an incorrect atmosphere, a process called decarburization.

This is the root cause of the inconsistency: an uncontrolled atmosphere leads to an uncontrolled chemical reaction. The common "fixes" fail because they ignore this chemical dimension entirely. You can have the world's most precise thermostat, but if you're using the wrong ingredients in your chemical recipe, the result will always be wrong.

Atmosphere as a Shield vs. Atmosphere as a Tool

Once you see the atmosphere as an active participant, you can control it for two primary purposes:

-

To Protect (Protective/Inert Atmospheres): For processes like bright annealing, the goal is to heat a part without changing it. Here, an inert atmosphere (like pure Nitrogen or Argon) acts as a perfect shield, displacing the destructive oxygen and ensuring the part comes out exactly as it went in.

-

To Enhance (Active Atmospheres): For processes like carburizing or nitriding, the goal is to intentionally change the surface. Here, the atmosphere becomes a precision tool, donating specific elements (like carbon or nitrogen) to the material's surface to create a hard, wear-resistant case.

Controlling this environment is the only way to escape the cycle of failure and achieve repeatable, predictable results.

From Uncontrolled Variable to Precision Instrument

To truly control a high-temperature chemical reaction, you need more than just a well-insulated box. You need a system engineered from the ground up to manage and maintain a specific, stable chemical environment. You need a furnace that treats the atmosphere with the same precision it treats temperature.

This is the principle upon which KINTEK furnaces are built. We design our systems not just to deliver heat, but to provide total environmental control.

-

For Ultimate Protection: Our Vacuum & Atmosphere Furnaces are engineered with superior seals, high-purity gas delivery systems, and powerful vacuum capabilities. This allows you to completely remove the reactive "air" and replace it with a precisely controlled inert or reducing atmosphere, eliminating the risk of oxidation and decarburization.

-

For Precision Surface Engineering: Our CVD/PECVD Systems and custom atmosphere furnaces feature advanced gas mixing and flow control. This transforms the atmosphere from a potential contaminant into a reliable instrument, allowing you to add specific elements to a material's surface with exceptional accuracy, batch after batch.

-

For Your Unique Process: Every material and every goal has a unique chemical requirement. Our deep customization capability is our greatest strength. We don’t offer a one-size-fits-all solution; we work with you to understand your specific process and engineer a furnace system that provides the exact atmospheric control you need to succeed.

Beyond Troubleshooting: Unlocking New Material Frontiers

When you finally gain absolute control over your furnace's atmosphere, the impact is transformative. You stop wasting time troubleshooting and start accelerating innovation.

With this newfound control, you can:

- Confidently work with sensitive materials like titanium, superalloys, and advanced ceramics, knowing they are fully protected from contamination.

- Develop robust, repeatable processes that can be seamlessly scaled from the lab to full production.

- Engineer advanced surfaces with precisely defined properties for hardness, wear resistance, and corrosion control.

- Shorten your R&D cycles dramatically because your results are reliable, allowing you to focus on the next breakthrough, not on fixing the last run.

Your challenge isn't just about managing heat; it's about mastering a complex chemical environment. Our expertise lies in designing the precise furnace solution your project demands, turning what was once your biggest variable into your most reliable tool. If you're ready to move from inconsistent results to predictable success, let's talk about the specific requirements of your application. Contact Our Experts.

Visual Guide

Related Products

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

Related Articles

- Beyond Heat: The Unseen Power of Environmental Control in Tube Furnaces

- The Controlled Void: How Vacuum Furnaces Forge the Materials of Tomorrow

- The Invisible Contaminant: Why Your Furnace Atmosphere is Sabotaging Your Results

- The Alchemy of Control: Mastering Material Properties with High-Temperature Tube Furnaces

- The Pursuit of Nothing: How Vacuum Furnace Control Defines Material Destiny