Electron bombardment heating systems offer a distinct advantage in Niobium surface studies by providing superior cleanliness and simulation accuracy compared to traditional methods. By utilizing electron beams on the backside of the sample holder, this technique achieves highly stable heating rates while preserving the vacuum integrity required for sensitive superconducting material research.

The core advantage of electron bombardment over resistance heating lies in its dual ability to maintain exceptional laboratory vacuum purity while precisely replicating the thermal dynamics of industrial manufacturing environments.

Achieving Industrial Fidelity

Simulating Real-World Fabrication

The primary strength of electron bombardment in this context is its ability to precisely simulate industrial environments.

Specifically, it replicates the conditions found in industrial superconducting cavity baking furnaces. This allows researchers to generate data that is directly transferable to actual manufacturing processes.

High-Precision Thermal Ramping

Electron bombardment systems offer exceptional control over temperature changes.

The reference highlights the ability to achieve stable heating rates of up to 1 °C/min. This slow, controlled ramp is critical for observing nuanced surface oxide reductions without inducing thermal shock or overshooting target temperatures.

Ensuring Material Purity

Maintaining Vacuum Chamber Integrity

When studying Niobium, particularly for superconducting applications, surface purity is paramount.

Traditional resistance heaters often risk introducing contaminants through outgassing. In contrast, electron bombardment helps maintain the high purity of the laboratory vacuum chamber during the thermal process.

Backside Heating Application

The system typically applies heat to the backside of the sample holder.

This configuration separates the heating mechanism from the sensitive surface being analyzed, further reducing the risk of direct interaction or contamination on the Niobium oxide layer.

Operational Considerations

Specificity of Application

While highly effective, this method is engineered for a specific purpose: simulating superconducting cavity baking.

Researchers should ensure their experimental goals align with the specific thermal profiles and ramp rates (e.g., the 1 °C/min stability) typical of these industrial processes. If the goal is to test rapid thermal spiking or non-industrial conditions, the precision of this simulation tool may not be the priority.

Making the Right Choice for Your Goal

- If your primary focus is Industrial Relevance: Choose electron bombardment to precisely mimic the baking furnaces used in superconducting cavity production.

- If your primary focus is Surface Purity: Rely on this method to maintain high vacuum chamber cleanliness and prevent contaminant interference during oxide reduction.

Electron bombardment provides the necessary bridge between laboratory-scale experimentation and industrial-scale reality for Niobium applications.

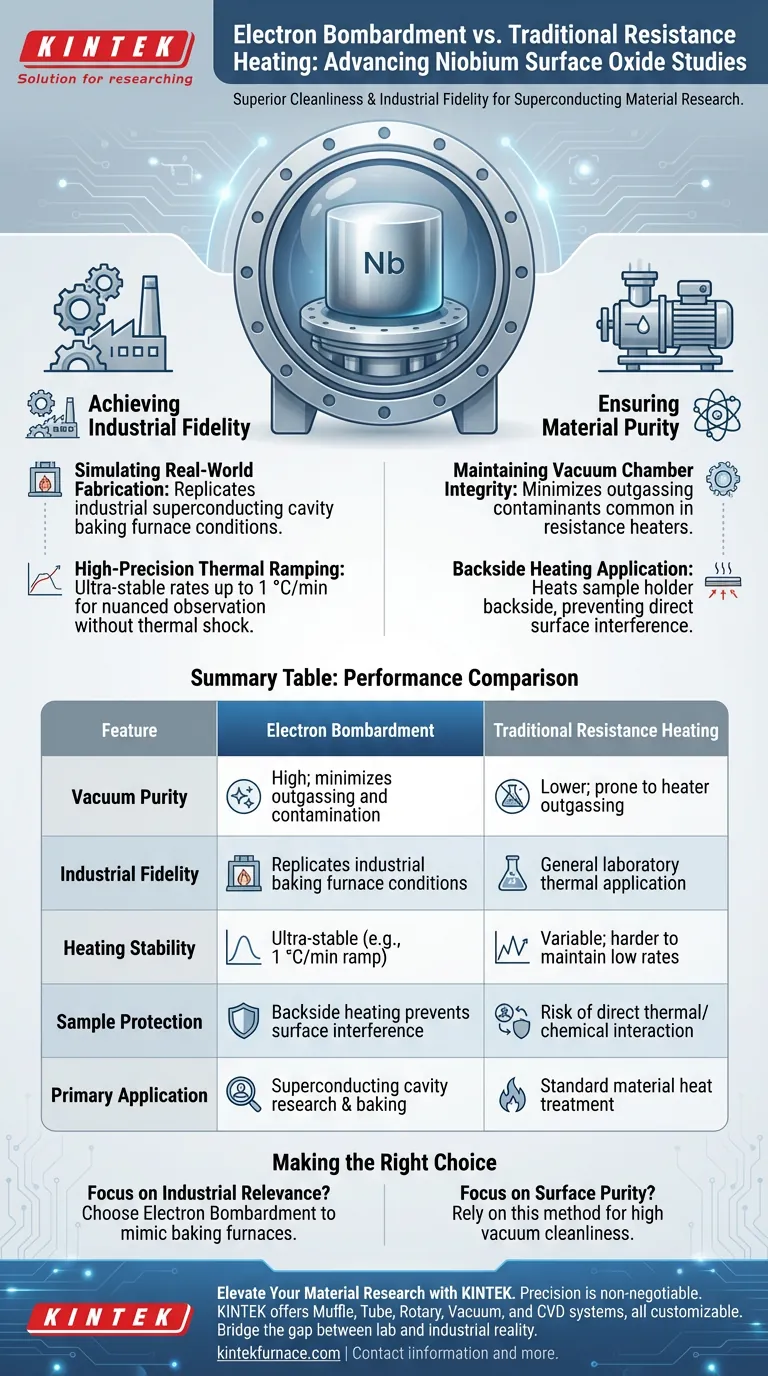

Summary Table:

| Feature | Electron Bombardment Heating | Traditional Resistance Heating |

|---|---|---|

| Vacuum Purity | High; minimizes outgassing and contamination | Lower; prone to heater outgassing |

| Industrial Fidelity | Replicates industrial baking furnace conditions | General laboratory thermal application |

| Heating Stability | Ultra-stable (e.g., 1 °C/min ramp) | Variable; harder to maintain low rates |

| Sample Protection | Backside heating prevents surface interference | Risk of direct thermal/chemical interaction |

| Primary Application | Superconducting cavity research & baking | Standard material heat treatment |

Elevate Your Material Research with KINTEK

Precision is non-negotiable when studying sensitive superconducting materials like Niobium. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory or industrial needs. Whether you require electron bombardment precision or specialized high-temp furnaces, our equipment ensures the purity and thermal control your project demands.

Ready to bridge the gap between lab experiments and industrial reality? Contact us today to consult with our specialists and find the perfect high-temperature solution for your application.

Visual Guide

References

- Alena Prudnikava, Jens Knobloch. <i>In-situ</i> synchrotron x-ray photoelectron spectroscopy study of medium-temperature baking of niobium for SRF application. DOI: 10.1088/1361-6668/ad4825

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why are SiC fragments added in microwave sintering? Boost Heating Uniformity and Prevent Cracks in Porous Ceramics

- What is the role of a laboratory vacuum drying oven in the preparation of fluoride-ion battery materials? Ensure Purity

- How does a rotary evaporator contribute to the concentration phase of TiO2 and ZrO2 pastes? Achieve Precision Viscosity

- Why is a precision temperature control system critical for protecting flexible substrates? Master Thermal Confinement

- What is the importance of the feeding system and ore distributing device? Unlock Peak Oil Shale Retorting Efficiency

- What is the primary function of an industrial-grade electric oven for concrete? Optimize High-Temp Material Testing

- What are the advantages of continuous furnaces? Boost Efficiency and Cut Costs in High-Volume Production

- What is the role of a laboratory oven in mushroom dehydration? Master Pre-Treatment for Precise Biochemical Analysis