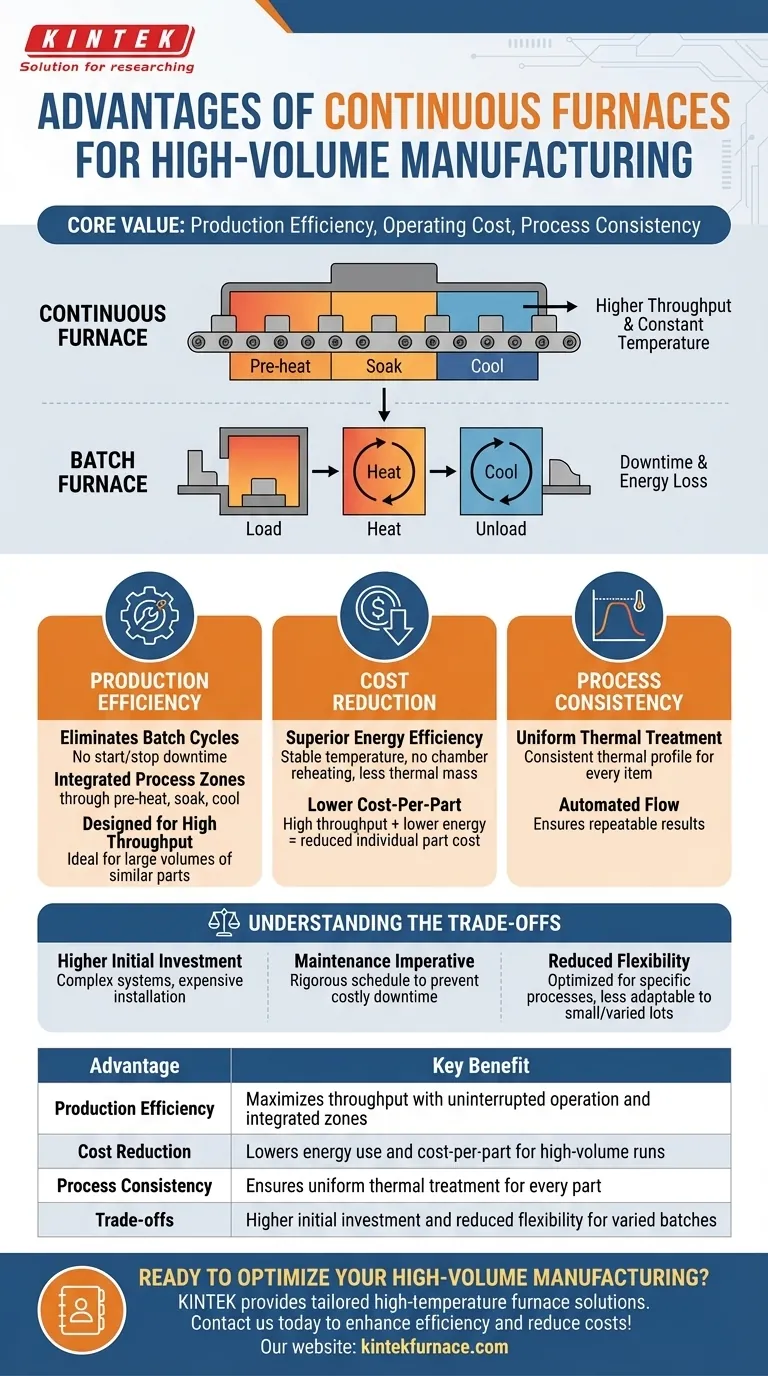

At their core, continuous furnaces provide significant advantages in production efficiency, operating cost, and process consistency for high-volume manufacturing. Unlike batch furnaces that heat and cool in cycles, continuous furnaces maintain a constant operating temperature and process parts in an uninterrupted flow. This design streamlines the heat treatment process, leading to higher throughput and lower energy consumption per part.

The fundamental trade-off is one of scale. While continuous furnaces require a higher initial investment and are less flexible, they dramatically lower the per-part cost in high-volume, repetitive manufacturing environments by optimizing energy use and maximizing throughput.

The Primary Driver: Production Efficiency

The most significant advantage of a continuous furnace is its ability to maximize output. This is achieved through a design philosophy centered on uninterrupted operation.

Eliminating the Batch Cycle

Continuous furnaces operate without stopping, processing a steady stream of products. This eliminates the downtime inherent in batch systems, where the furnace must be loaded, heated, cooled, and unloaded for each cycle.

Integrated Process Zones

These furnaces are often designed with multiple zones for pre-heating, soaking, and cooling. Parts move automatically through each stage, which shortens the total processing time and ensures a consistent thermal profile for every item.

Designed for High Throughput

The combination of continuous operation and rapid processing cycles makes these furnaces the ideal solution for high-volume manufacturing. They are engineered to handle a large quantity of similar parts with maximum efficiency.

A Deeper Look at Cost Reduction

Beyond speed, the design of a continuous furnace directly translates into lower long-term operating costs in the right application.

Superior Energy Efficiency

A continuous furnace maintains a stable temperature in its heating zones, avoiding the massive energy loss of repeatedly heating and cooling an entire furnace chamber. Furthermore, they often do not require heavy fixtures like baskets or racks, which reduces the total thermal mass that needs to be heated with each part.

Lower Cost-Per-Part

By combining high throughput with lower energy consumption, the operational cost attributed to each individual part is significantly reduced. This makes continuous furnaces a highly cost-effective choice for mass production.

Understanding the Trade-offs

No technology is a universal solution. The advantages of a continuous furnace come with specific limitations that make it unsuitable for certain operations.

Higher Initial Investment

Continuous furnaces are complex systems that are more expensive to purchase, install, and commission compared to their batch counterparts. This high upfront cost is a primary consideration.

The Maintenance Imperative

To ensure reliable, continuous operation and prevent costly downtime, these furnaces require a rigorous and often more frequent maintenance schedule. Their complexity can also make repairs more involved.

Reduced Flexibility

A continuous furnace is typically optimized for a specific process and part type. They lack the flexibility of batch furnaces to easily handle small, varied lots or frequent changes in processing requirements.

Making the Right Choice for Your Operation

Selecting the correct furnace technology depends entirely on your production goals and operational realities.

- If your primary focus is high-volume, repetitive production: A continuous furnace offers the lowest cost-per-part and the highest throughput, making it the superior long-term investment.

- If your primary focus is processing diverse, low-volume batches: A batch furnace provides essential flexibility and a much lower initial cost, making it the more practical and economical choice.

- If your primary focus is process cleanliness and environmental compliance: A continuous vacuum furnace provides a sealed, controlled environment that prevents contamination and meets stringent regulatory standards.

Ultimately, choosing the right furnace is a strategic decision that directly impacts your operational efficiency and final product quality.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Production Efficiency | Maximizes throughput with uninterrupted operation and integrated zones |

| Cost Reduction | Lowers energy use and cost-per-part for high-volume runs |

| Process Consistency | Ensures uniform thermal treatment for every part |

| Trade-offs | Higher initial investment and reduced flexibility for varied batches |

Ready to optimize your high-volume manufacturing with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the heating process work in rotary tube furnaces? Achieve Uniform Heat for Powders and Granules

- How is heat transferred to the furnace tubes in a rotary tube furnace? Master Uniform Heating for Your Materials

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- How does a rotary tube furnace operate? Master Continuous Heating for Uniform Results