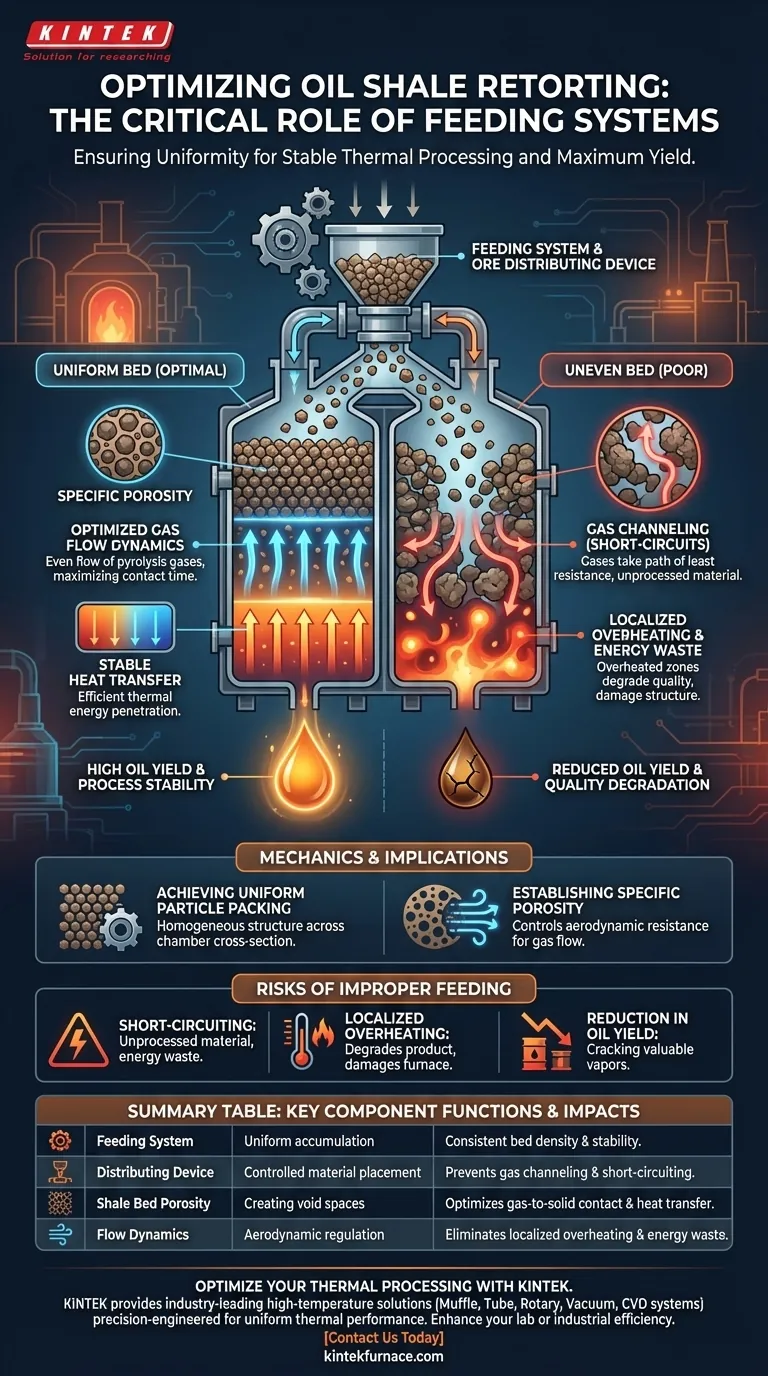

The feeding system and ore distributing device are the critical regulators of retorting efficiency. Their primary function is to ensure that oil shale particles are uniformly distributed and tightly packed as they enter the retorting chamber. This mechanical consistency is the absolute prerequisite for stable thermal processing and optimal chemical reactions.

The operational success of a retort relies on creating a shale bed with specific, consistent porosity. By ensuring uniform accumulation, these devices prevent gas flow irregularities and thermal instability, which are the primary causes of reduced oil yield.

The Mechanics of Bed Formation

Achieving Uniform Particle Packing

The fundamental role of these devices is to manage how raw material enters the furnace. Rather than random dumping, the system must place oil shale particles to create a homogeneous structure. This ensures that the material density is consistent across the entire cross-section of the chamber.

Establishing Specific Porosity

The result of uniform packing is a material bed with specific porosity. Porosity refers to the void spaces between the shale particles where gases must flow. Controlling this variable is essential because it dictates the aerodynamic resistance within the furnace.

Thermal and Chemical Implications

Optimizing Gas Flow Dynamics

A uniformly packed bed guarantees the even flow of pyrolysis gases. When porosity is consistent, gases rise through the bed predictably rather than channeling through loose spots. This maximizes the contact time between the heat source and the raw shale.

Ensuring Stable Heat Transfer

The retorting process relies on stable heat transfer from the furnace walls to the material. Uniform distribution ensures that there are no insulating pockets or overly dense clusters. This allows thermal energy to penetrate the shale bed efficiently and evenly.

Understanding the Risks of Improper Feeding

The Danger of Short-Circuiting

If the distributing device fails to pack the bed evenly, gases will take the path of least resistance. This creates "short-circuits" where hot gases bypass large sections of the ore. The result is unprocessed raw material and significant energy waste.

The Impact of Localized Overheating

Uneven distribution often leads to localized overheating. When heat is not absorbed uniformly, specific zones can exceed target temperatures. This degrades the quality of the product and can damage the furnace structure over time.

Reduction in Oil Yield

The ultimate consequence of poor feeding is a measurable drop in oil yield. Overheated areas may crack valuable oil vapors into less valuable gases. Simultaneously, under-heated areas fail to release their oil content entirely.

Making the Right Choice for Your Goal

While the furnace design grabs attention, the feeding mechanism often dictates the actual performance metrics.

- If your primary focus is Maximizing Yield: Ensure the distributing device is calibrated to maintain strict porosity standards to prevent gas channeling.

- If your primary focus is Process Stability: Prioritize feeding systems that guarantee uniform wall-to-center particle density to stabilize heat transfer.

Consistency at the intake prevents chaos in the reactor.

Summary Table:

| Key Component | Primary Function | Impact on Retorting |

|---|---|---|

| Feeding System | Uniform particle accumulation | Ensures consistent bed density & stability |

| Distributing Device | Controlled material placement | Prevents gas channeling & short-circuiting |

| Shale Bed Porosity | Creating void spaces | Optimizes gas-to-solid contact & heat transfer |

| Flow Dynamics | Aerodynamic regulation | Eliminates localized overheating & energy waste |

Optimize Your Thermal Processing with KINTEK

Don't let inefficient material distribution compromise your production yield. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to ensure uniform thermal performance.

Whether you need custom-built furnaces or expert R&D support, our team is ready to enhance your lab or industrial efficiency. Contact us today to discover how our customizable manufacturing can stabilize your most critical chemical reactions.

Visual Guide

References

- Lixin Zhao, Luwei Pan. Numerical Study of the Combustion-Flow-Thermo-Pyrolysis Process in an Innovative Externally Heated Oil Shale Retort. DOI: 10.3390/sym17071055

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity

- What is the purpose of adding phosphorus pentoxide (P2O5) as a desiccant? Ensure Deep Electrolyte Regeneration

- What is the function of nitrogen purging during the startup phase of the pyrolysis process? Ensure Safety and Quality

- What role do RTP or continuous sintering furnaces play in solar cell electrode formation? Optimize Your Firing Process

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- Why is an industrial forced air drying oven required for drying banana slices? Unlock Precision & Nutritional Quality

- Why is a nitrogen protection system necessary for LPF resin synthesis? Ensure Purity in Lab Polymerization

- Why is it necessary to use a vacuum drying oven for porous graphene cathodes? Ensure Peak Battery Performance