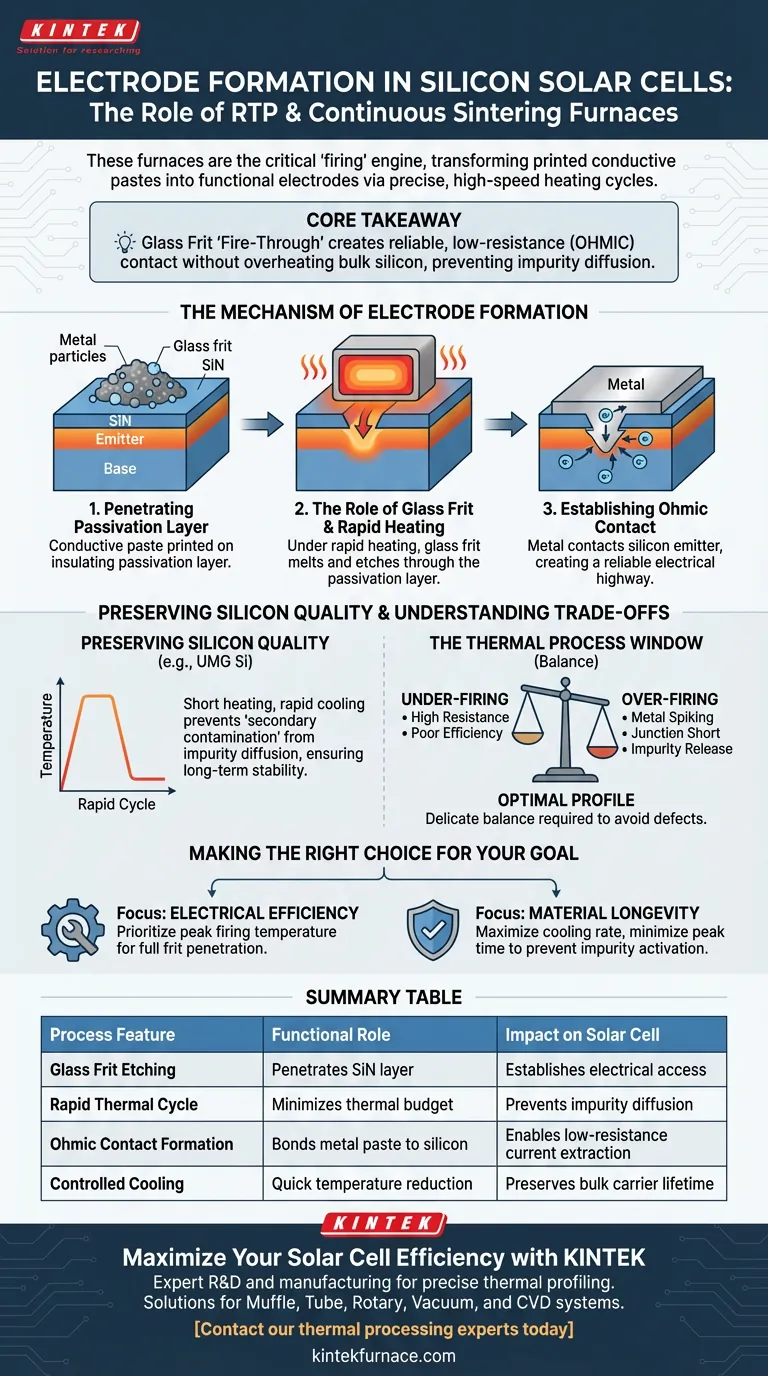

Rapid Thermal Processing (RTP) and continuous sintering furnaces serve as the critical "firing" engine in silicon solar cell manufacturing. They transform printed conductive pastes into functional electrodes by subjecting the wafer to precise, high-speed heating and cooling cycles. This thermal process forces the paste components to penetrate insulating surface layers, establishing the necessary electrical connection to extract power from the cell.

Core Takeaway The primary function of these furnaces is to enable glass frit "fire-through", creating a reliable low-resistance (ohmic) contact between the metal electrode and the silicon. By utilizing rapid thermal cycles, the process establishes this contact without overheating the bulk silicon, thereby preventing impurity diffusion that would degrade the cell's long-term efficiency.

The Mechanism of Electrode Formation

Penetrating the Passivation Layer

Modern silicon solar cells are coated with a passivation layer (often silicon nitride) that acts as an electrical insulator. To extract current, the metal electrode must breach this layer.

The Role of Glass Frit

Conductive pastes contain glass frit (powdered glass). Under the rapid heating of an RTP furnace, this glass melts and effectively dissolves or "etches" through the underlying passivation layer.

Establishing Ohmic Contact

Once the passivation layer is breached, the metal in the paste (usually silver or aluminum) comes into direct contact with the silicon emitter. This creates a reliable ohmic contact, allowing charge carriers to flow freely from the semiconductor into the metal grid lines.

Preserving Silicon Quality

Preventing Secondary Contamination

For sensitive materials, specifically upgraded metallurgical grade (UMG) silicon, prolonged exposure to high temperatures is dangerous. It can activate impurities or cause them to diffuse into active regions of the cell.

The Importance of Rapid Cycles

RTP furnaces mitigate this risk by using optimized, short-duration heating profiles. The rapid cooling phase is equally critical.

Ensuring Long-Term Stability

By limiting the thermal budget, the furnace prevents "secondary contamination" from these internal impurities. This preservation of bulk quality ensures the long-term stability and operational lifetime of the final solar module.

Understanding the Trade-offs

The Thermal Process Window

There is a delicate balance between under-firing and over-firing.

Risk of Under-Firing

If the temperature is too low or the time too short, the glass frit will not fully penetrate the passivation layer. This results in high contact resistance and poor cell efficiency.

Risk of Over-Firing

Conversely, excessive heat or duration can cause the metal to spike too deeply into the silicon, potentially shorting the junction. Furthermore, as noted with UMG silicon, excessive heat degrades the bulk carrier lifetime by releasing impurities.

Making the Right Choice for Your Goal

Achieving optimal electrode formation requires tuning your furnace profile to the specific chemistry of your paste and the quality of your silicon.

- If your primary focus is electrical efficiency: Prioritize the peak firing temperature to ensure the glass frit fully penetrates the passivation layer for minimum contact resistance.

- If your primary focus is material longevity (especially with UMG silicon): Focus on maximizing the cooling rate and minimizing peak hold time to prevent impurity activation and secondary contamination.

The ultimate goal is to establish a robust electrical highway on the surface without compromising the integrity of the silicon beneath it.

Summary Table:

| Process Feature | Functional Role | Impact on Solar Cell |

|---|---|---|

| Glass Frit Etching | Penetrates the SiN passivation layer | Establishes electrical access to the silicon emitter |

| Rapid Thermal Cycle | Minimizes thermal budget | Prevents impurity diffusion and secondary contamination |

| Ohmic Contact Formation | Bonds metal paste to silicon | Enables low-resistance current extraction |

| Controlled Cooling | Quick temperature reduction | Preserves bulk carrier lifetime and material stability |

Maximize Your Solar Cell Efficiency with KINTEK

Precise thermal profiling is the difference between a high-performance solar cell and a degraded wafer. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized high-temperature lab furnaces. Whether you are optimizing glass frit fire-through or managing the delicate thermal budget of UMG silicon, our customizable solutions are designed to meet your unique research and production needs.

Ready to elevate your electrode formation process? Contact our thermal processing experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Production of upgraded metallurgical-grade silicon for a low-cost, high-efficiency, and reliable PV technology. DOI: 10.3389/fphot.2024.1331030

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Spark Plasma Sintering SPS Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What are some common applications of PVD? Boost Performance with Advanced Thin-Film Coatings

- What is the role of the shaft-type electric furnace in chlorination? Powering Zirconium Sponge Production

- What are some examples of high-temperature industrial heating processes? Explore Key Applications and Benefits

- What is the function of a vacuum drying oven in SFRP processing? Preserve Material Integrity & Prevent Degradation

- How is a vacuum impregnation system utilized during wood leaching resistance tests? Achieve Full Saturation for EN 84

- How does a blast drying oven support the preparation of rubidium-doped mesoporous bioactive glass? Optimized Synthesis

- What is the purpose of using a vacuum drying oven for mineral powders? Optimize Polymer Bonding and Density