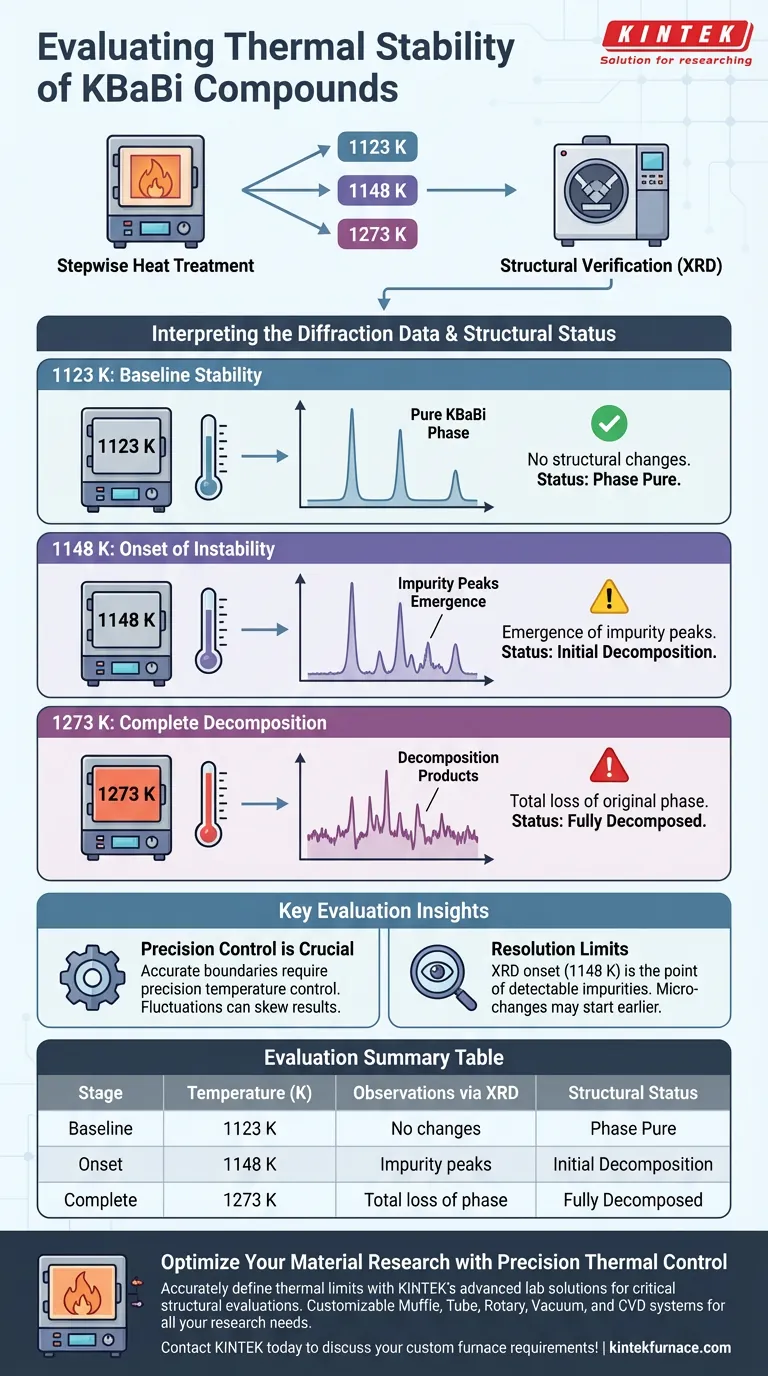

The thermal stability of KBaBi compounds is determined through a systematic process of stepwise heat treatment followed by structural verification. To evaluate these materials, samples are subjected to precise temperatures—specifically 1123 K, 1148 K, and 1273 K—and subsequently analyzed using powder X-ray diffraction (XRD). This combination allows researchers to visualize changes in the crystal lattice and identify exactly when the material begins to degrade.

By correlating specific treatment temperatures with the appearance of impurity peaks in the diffraction pattern, this method defines the precise decomposition range. It establishes the upper thermal boundaries necessary for the practical application of new Zintl phase materials.

The Evaluation Methodology

Stepwise Heat Treatment

The core of this evaluation involves subjecting the KBaBi samples to a rigorous heating schedule.

Researchers treat the material at specific, incremental temperature points: 1123 K, 1148 K, and 1273 K.

This stepwise approach is critical because it isolates the thermal effects at distinct energy levels, preventing ambiguity regarding when structural changes occur.

Structural Verification via XRD

Once the heat treatment is complete, powder X-ray diffraction serves as the diagnostic tool.

XRD provides a "fingerprint" of the material's crystal structure.

By comparing the diffraction patterns of treated samples against the expected pattern of the pure compound, researchers can detect minute structural deviations.

Interpreting the Diffraction Data

Identifying the Onset of Instability

The primary indicator of thermal instability is the emergence of unexpected diffraction peaks.

According to the data, impurity peaks appear at 1148 K.

The presence of these extra peaks in the XRD pattern signals that the KBaBi compound has begun to break down or react, marking the start of its thermal limit.

Confirming Complete Decomposition

As the temperature increases, the degradation of the material accelerates.

At 1273 K, the analysis reveals complete decomposition.

In the XRD data, this is characterized by the total loss of the original KBaBi phase signatures, replaced entirely by the patterns of decomposition products.

Understanding the Trade-offs

The Necessity of Precision Control

Accurate evaluation is heavily dependent on the quality of the equipment used.

Defining the boundary between stability and decomposition requires precision temperature control equipment.

Any fluctuation in the heat treatment environment can skew the results, making the material appear more or less stable than it actually is.

Resolution Limits

While XRD is powerful, it is limited by its sensitivity to low-volume phases.

The "onset" of decomposition at 1148 K represents the point where impurities become detectable by the instrument.

Micro-structural changes may begin slightly before this threshold, meaning the absolute safe operating temperature is likely just below the first detected impurity peak.

Determining Operational Limits

The results of this evaluation provide a clear guide for utilizing KBaBi compounds.

- If your primary focus is defining safe operating limits: You must treat 1148 K as the critical threshold where structural integrity is compromised by the formation of impurities.

- If your primary focus is analyzing failure modes: You should examine the data at 1273 K to understand the final breakdown products of the material after complete decomposition.

This evaluation confirms that thermal stability is not a single point, but a range defined by the transition from phase purity to total structural collapse.

Summary Table:

| Evaluation Stage | Temperature (K) | Observations via XRD | Structural Status |

|---|---|---|---|

| Baseline Stability | 1123 K | No structural changes | Phase Pure |

| Onset of Instability | 1148 K | Emergence of impurity peaks | Initial Decomposition |

| Complete Breakdown | 1273 K | Total loss of original phase | Fully Decomposed |

Optimize Your Material Research with Precision Thermal Control

Accurately defining the thermal limits of Zintl phases like KBaBi requires absolute temperature uniformity and reliability. KINTEK provides the advanced lab solutions necessary for critical structural evaluations.

Backed by expert R&D and manufacturing, we offer a wide range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific research temperatures and atmospheres. Whether you are identifying decomposition thresholds or analyzing phase transitions, our high-temp furnaces deliver the precision you need.

Ready to elevate your thermal analysis? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Investigation of a Ternary Zintl Phase KBaBi: Synthesis, Crystal Structure, and Preliminary Transport Properties. DOI: 10.1002/zaac.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary function of glass matrices in HLW vitrification? Achieve Safe Radioactive Waste Immobilization

- What role does an electric thermostatic drying oven play in the pre-treatment of Fe–Ni/AC catalysts? Essential Guide

- Why is a silicone oil bath preferred for T5 aging of HPDC magnesium alloys? Precision Heat for Peak Strength

- What is the significance of preheating UHPC molds? Ensure Safety & Longevity with High-Temp Furnaces

- Why is a laboratory vacuum drying oven important for the post-treatment stage of electrode plates? Enhance Battery Life

- What is the significance of using a hydrogen etching process in a reaction chamber? Mastering SiC Surface Preparation

- What are the advantages of using electron bombardment heating systems for Niobium? Achieve Industrial Fidelity

- How does a Zinc Oxide (ZnO) catalyst affect PET pyrolysis? Optimize Yields & Efficiency