The laboratory vacuum drying oven is the definitive tool for ensuring the chemical purity and structural integrity of electrode plates. By creating a low-pressure environment, the oven significantly lowers the boiling point of residual solvents and moisture. This allows for the complete removal of contaminants at lower temperatures, ensuring the electrode is thoroughly dried without subjecting the active materials to damaging thermal stress.

The vacuum drying process serves a dual purpose: it eliminates trace contaminants that trigger battery failure while simultaneously protecting the physical structure of the electrode from oxidation and thermal degradation.

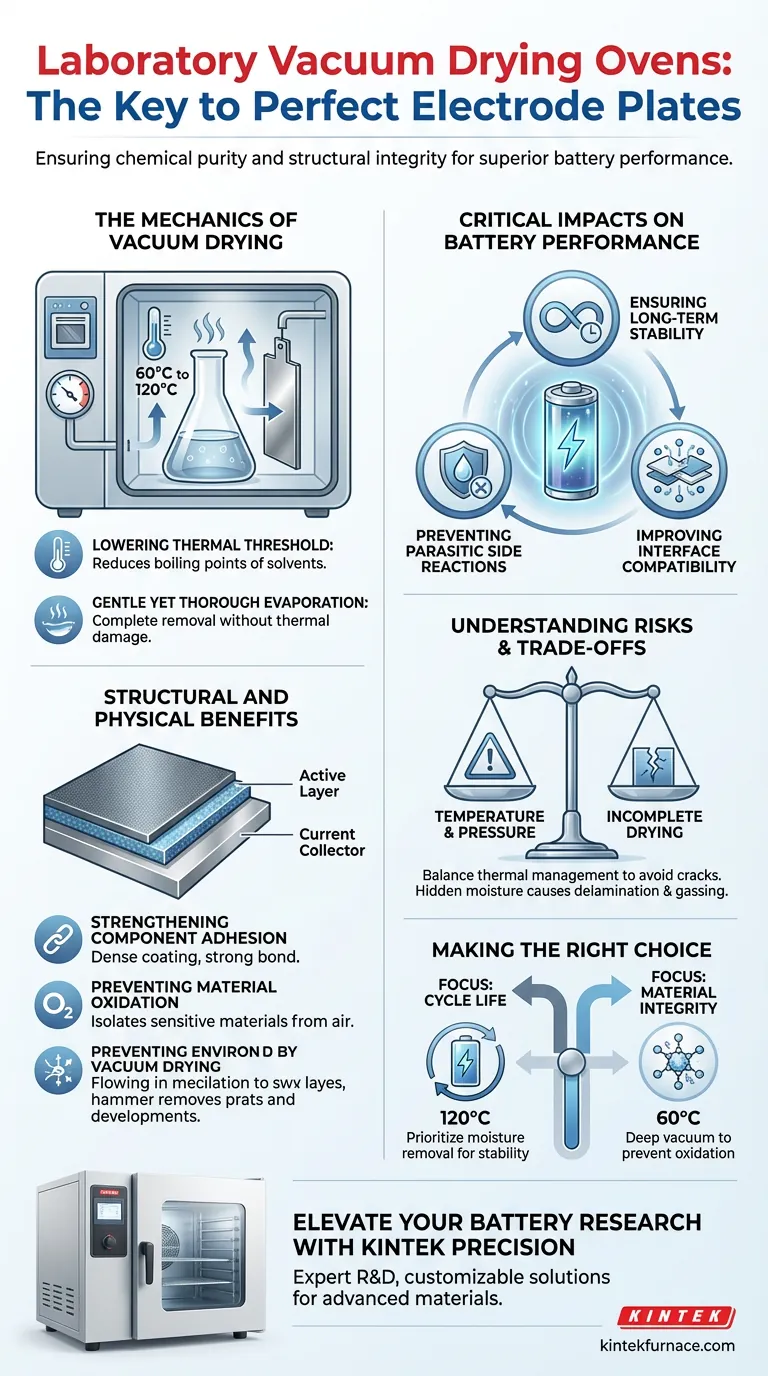

The Mechanics of Vacuum Drying

Lowering the Thermal Threshold

The primary function of the vacuum oven is to manipulate the physical properties of liquids. By reducing the ambient pressure, the oven lowers the boiling point of solvents and water.

Gentle Yet Thorough Evaporation

This pressure reduction allows you to evaporate stubborn solvents, such as NMP, or trace moisture at much lower temperatures (e.g., 60 °C to 120 °C) than would be required at atmospheric pressure. This ensures complete drying without "cooking" the electrode.

Critical Impacts on Battery Performance

Preventing Parasitic Side Reactions

Trace moisture is a silent killer in battery chemistry. If left in the electrode, water can cause the electrolyte to decompose during battery cycling.

Ensuring Long-Term Stability

By thoroughly removing these traces, the vacuum oven prevents the side reactions that degrade capacity over time. This is essential for maintaining the long-term cyclic stability of the battery cells.

Improving Interface Compatibility

A dry, clean surface is required for the active material to interact correctly with the electrolyte. Proper vacuum drying optimizes this interface, ensuring efficient ion transfer.

Structural and Physical Benefits

Strengthening Component Adhesion

The post-treatment drying stage is not just about chemistry; it is about physical bonding. The process helps form a dense coating, strengthening the adhesion between the active layer and the current collector.

Preventing Material Oxidation

Certain active materials (such as Lanthanum-doped Cobalt Telluride) are highly sensitive to oxygen. The vacuum environment isolates the material from air, preventing oxidation and degradation during the drying phase.

Understanding the Risks and Trade-offs

Balancing Temperature and Pressure

While the vacuum allows for lower temperatures, thermal management is still critical. Even in a vacuum, excessive heat can lead to coating cracks or binder failure.

The Cost of Incomplete Drying

Failing to achieve a sufficient vacuum level results in residual solvents remaining deep within the porous electrode structure. This "hidden" moisture is often the root cause of unexpected delamination or gassing later in the battery's life.

Making the Right Choice for Your Goal

To maximize the effectiveness of your electrode post-treatment, tailor your drying strategy to your specific materials.

- If your primary focus is Cycle Life: Prioritize the complete removal of trace moisture at 120 °C to prevent electrolyte decomposition and ensure long-term stability.

- If your primary focus is Material Integrity: Utilize lower temperatures (around 60 °C) in a deep vacuum to prevent the oxidation of air-sensitive active materials.

Ultimately, the vacuum drying oven is not merely a dryer; it is a stabilization chamber that defines the reliability of the final energy storage device.

Summary Table:

| Feature | Impact on Electrode Post-Treatment |

|---|---|

| Lowered Boiling Point | Removes stubborn solvents like NMP at gentle, low temperatures. |

| Vacuum Environment | Prevents oxidation and degradation of sensitive active materials. |

| Moisture Elimination | Stops parasitic reactions and electrolyte decomposition in cells. |

| Structural Integrity | Enhances coating density and adhesion to current collectors. |

| Thermal Control | Minimizes thermal stress to prevent coating cracks and binder failure. |

Elevate Your Battery Research with KINTEK Precision

High-performance energy storage starts with perfect electrode preparation. At KINTEK, we understand that moisture is the enemy of battery longevity. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems tailored specifically for advanced material science.

Our laboratory vacuum drying ovens provide the deep-vacuum stability and uniform thermal management required to prevent material oxidation and ensure long-term cyclic stability. Whether you are working with air-sensitive compounds or high-density coatings, our systems are fully customizable to meet your unique research needs.

Ready to optimize your post-treatment process? Contact us today to discuss your customized furnace solution.

Visual Guide

References

- Jeong Yeon, Ho Seok Park. Self‐supported VO<sub>2</sub> on polydopamine‐derived pyroprotein‐based fibers for ultrastable and flexible aqueous zinc‐ion batteries. DOI: 10.1002/cey2.469

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of treating ADSC powders with hydrogen? Purify Your Material for Superior Conductivity

- Why is it necessary to thoroughly dry biomass raw materials before starting a pyrolysis experiment? Improve Yields

- T6 vs T73 State in AA7050 Alloy: How to Choose the Right Two-Stage Aging Process for Strength and Durability

- How does a high-temperature TOC analyzer assess RCM NSs performance? Verify Mineralization vs Decolorization

- What is the significance of using a laboratory vacuum drying oven during the catalyst recovery phase of depolymerization?

- What is the function of a planetary high-energy ball mill in Al2O3/TiC ceramics? Achieve Sub-Micron Precision Today

- Why is industrial-grade nitrogen flow introduced during the biochar pyrolysis process? Ensure Safety and Quality

- What role does a laboratory drying oven play in the post-treatment of Cu/ZIF-8 catalysts? Ensuring Structural Integrity