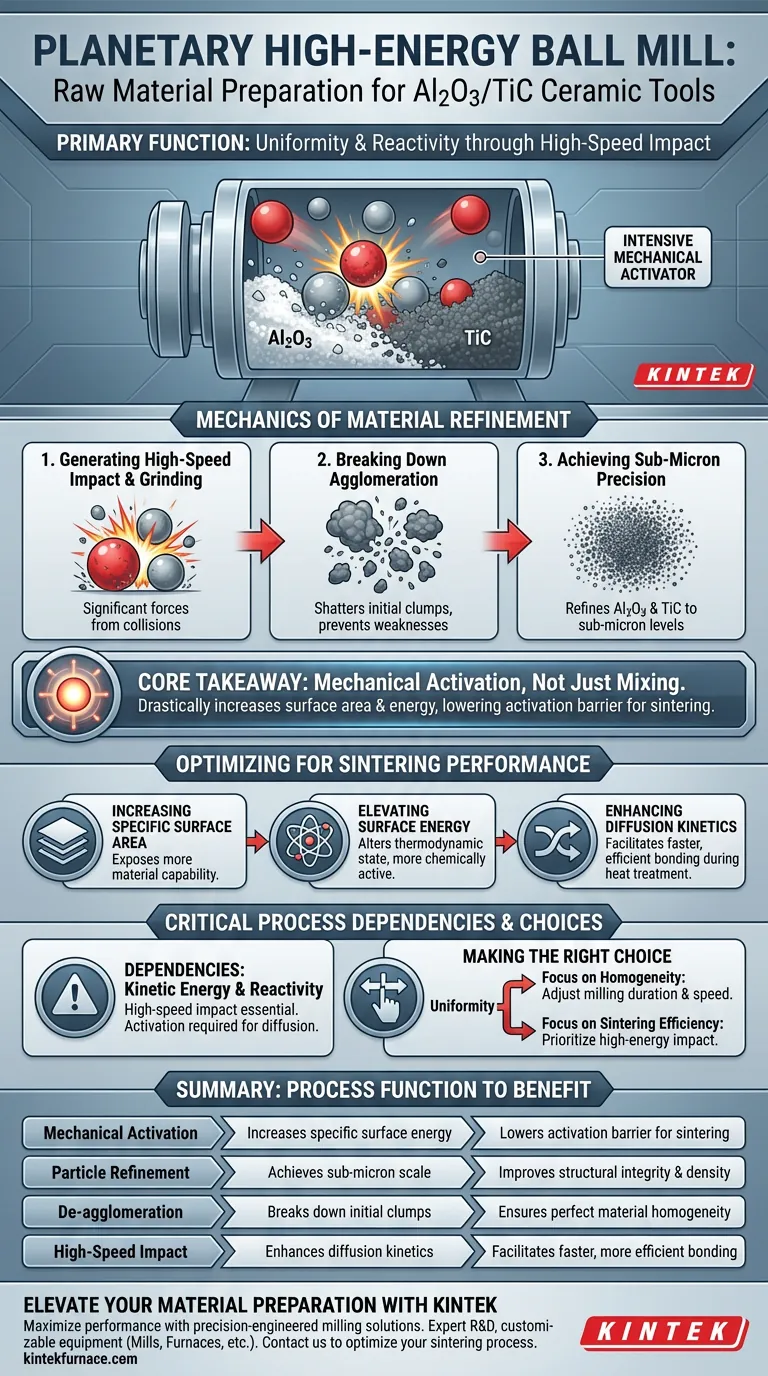

The primary function of a planetary high-energy ball mill in this context is to act as an intensive mechanical activator that ensures uniformity and reactivity. Through high-speed impact and grinding forces, it blends alumina (Al2O3) and titanium carbide (TiC) powders while simultaneously refining their particle size to sub-micron levels. This process breaks down initial agglomerations, creating a homogeneous mixture critical for the structural integrity of the final tool.

Core Takeaway The ball mill does more than simply mix materials; it mechanically activates them. By drastically increasing the specific surface area and surface energy of the powder, the milling process lowers the activation barrier for the subsequent sintering phase, ensuring superior diffusion and reactivity.

The Mechanics of Material Refinement

Generating High-Speed Impact

The planetary ball mill utilizes distinct high-speed mechanics to process the raw materials. It generates significant impact and grinding forces through the collision of grinding balls and the powder mixture.

Breaking Down Agglomeration

Raw ceramic powders naturally tend to clump together, or agglomerate. The high-energy milling process physically shatters these initial agglomerations, preventing structural weaknesses in the final composite.

Achieving Sub-Micron Precision

To create a high-performance ceramic tool, standard powder sizes are often insufficient. The milling process refines the Al2O3 and TiC particles down to sub-micron levels, a scale necessary for advanced material properties.

Optimizing for Sintering Performance

Increasing Specific Surface Area

As the particle size decreases during milling, the specific surface area of the powder increases effectively. This exposes more material capability to the binding process.

Elevating Surface Energy

The intense physical grinding does not just change the shape of the particles; it alters their thermodynamic state. The process increases the surface energy of the powder, making the material more chemically active.

Enhancing Diffusion Kinetics

The ultimate goal of this preparation phase is to facilitate the sintering process that follows. The increased surface energy and area significantly enhance diffusion kinetics, allowing the materials to bond and react more efficiently during heat treatment.

Critical Process Dependencies

The Necessity of Kinetic Energy

It is important to understand that this process relies heavily on the "high-energy" aspect of the equipment. Standard mixing without high-speed impact is insufficient to achieve the required sub-micron refinement.

Reactivity Requires Mechanical Activation

Mere blending of Al2O3 and TiC will not produce the same quality of ceramic tool. The physical increase in reactivity is a direct result of the specific mechanical forces applied; without this intense activation, the diffusion kinetics required for successful sintering may not be realized.

Making the Right Choice for Your Goal

To ensure the success of your Al2O3/TiC ceramic tool project, consider the specific requirements of your raw material preparation:

- If your primary focus is material homogeneity: Ensure the milling duration and speed are sufficient to break down all initial agglomeration for a perfectly uniform mix.

- If your primary focus is sintering efficiency: Prioritize high-energy impact settings to maximize surface energy, which drives the diffusion kinetics needed for densification.

By leveraging the high-energy ball mill to refine particle size and boost surface energy, you set the foundation for a high-performance, durable ceramic composite.

Summary Table:

| Process Function | Impact on Raw Material | Benefit to Final Ceramic Tool |

|---|---|---|

| Mechanical Activation | Increases specific surface energy | Lowers activation barrier for sintering |

| Particle Refinement | Achieves sub-micron scale | Improves structural integrity and density |

| De-agglomeration | Breaks down initial clumps | Ensures perfect material homogeneity |

| High-Speed Impact | Enhances diffusion kinetics | Facilitates faster and more efficient bonding |

Elevate Your Material Preparation with KINTEK

Maximize the performance of your Al2O3/TiC ceramic tools with precision-engineered milling solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory equipment including high-energy planetary ball mills and advanced high-temp furnaces (Muffle, Tube, Vacuum, and CVD systems), all fully customizable to meet your unique research and production needs.

Don't settle for inconsistent results. Contact us today to optimize your sintering process and see how our expertise can drive your innovation.

Visual Guide

References

- Alejandro Padilla-González, I.A. Figueroa. Development and Mechanical Characterization of a CoCr-Based Multiple-Principal-Element Alloy. DOI: 10.1007/s13632-024-01111-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- What is the significance of heat treatment for Ni-Rich NCM811? Master Precise Battery Cathode Synthesis

- What role does an industrial electric furnace play in PAI? Master Thermal Preparation for Metal Matrix Composites

- How does a Rapid Thermal Processing (RTP) system function? Optimize Nanowire Device Performance Today

- How does a batch furnace differ from a continuous furnace? Choose the Right Furnace for Your Production Needs

- What is the primary purpose of drying and calcination in nickel laterite ore pretreatment? Optimize Your Smelting Efficiency

- Why is high-precision temperature control at 800 °C critical for BCMoMn catalyst heterostructures?

- How does a vacuum drying oven contribute to biodiesel moisture control? Ensure Fuel Quality & Stability

- What are the advantages of HTL reactors for algae? Optimize Biomass Conversion Without Pre-Drying