Vacuum drying ovens and constant temperature ovens are critical instruments for the final purification stage of biodiesel refining. Specifically employed after the washing process, these ovens utilize a controlled environment heated to 80°C to evaporate residual moisture and remove trace alcohols without degrading the fuel.

By maintaining a precise temperature of 80°C, these ovens facilitate the removal of volatile contaminants while preventing the accelerated oxidation that occurs at higher temperatures. This ensures the biodiesel remains chemically stable for accurate quality testing.

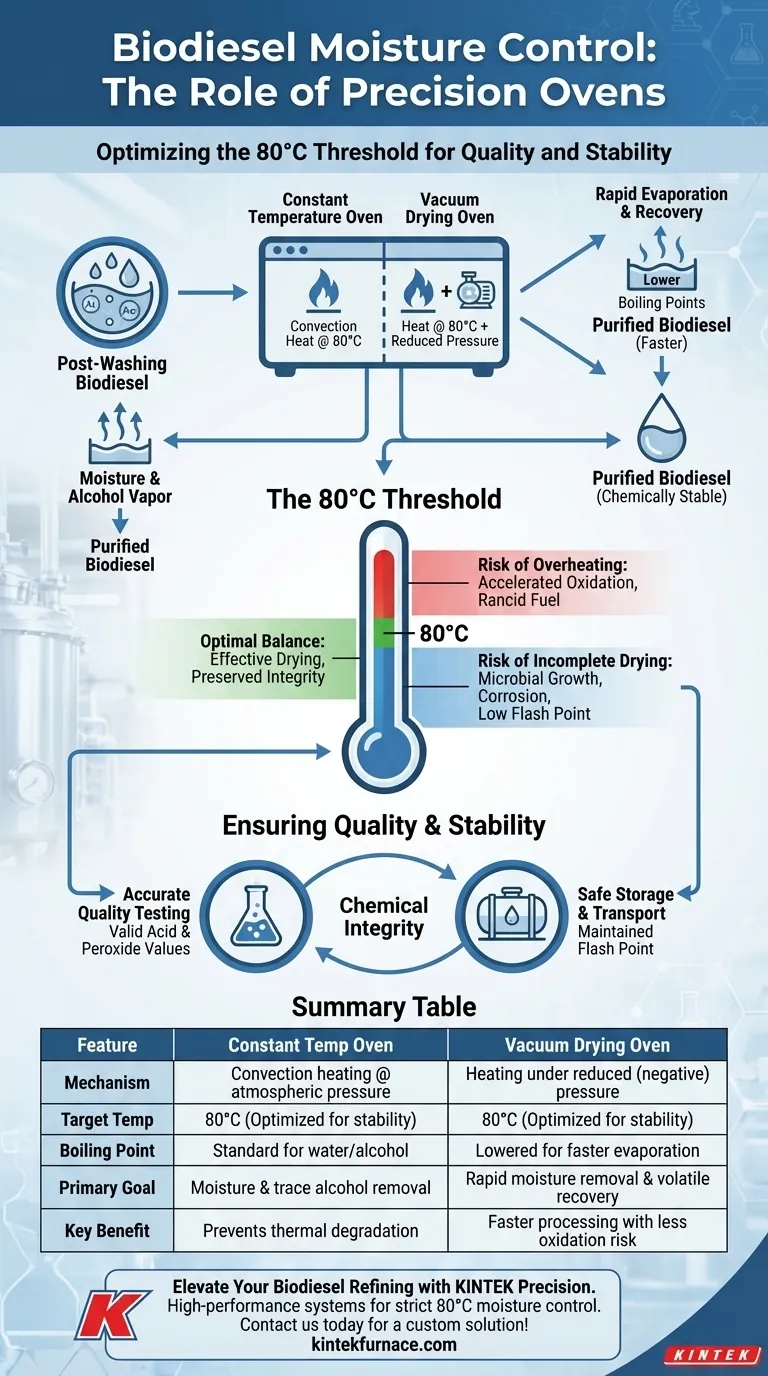

The Mechanics of Moisture Removal

Targeting Post-Washing Residue

Once biodiesel has undergone the washing steps, it is typically free of soaps but retains significant moisture and unreacted alcohols.

The oven serves as a drying chamber. It subjects the liquid to sustained heat, forcing these contaminants out of the mixture.

Efficient Removal of Volatiles

Water and alcohols (such as methanol) have lower boiling points or higher volatility than the biodiesel itself.

By heating the product, the oven increases the vapor pressure of these impurities. This allows them to evaporate efficiently, leaving behind purified biodiesel.

The Role of Vacuum Pressure

While a constant temperature oven relies on heat alone, a vacuum drying oven adds reduced pressure to the process.

This lowers the boiling point of water and alcohol, allowing them to evaporate more rapidly. This makes the drying process faster and more thorough than heat alone.

The Critical Role of Temperature Precision

The 80°C Threshold

The primary reference establishes 80°C as the optimal processing temperature for this stage.

This specific temperature is a calculated balance. It is high enough to effectively drive off moisture but remains below the threshold where significant thermal degradation begins.

Preventing Accelerated Oxidation

Biodiesel is chemically sensitive to excessive heat.

If the drying temperature spikes uncontrolled, the heat facilitates a reaction with oxygen. This accelerated oxidation degrades the fuel before it even leaves the refinery.

Preserving Chemical Integrity

Strict temperature control ensures that chemical analysis results remain valid.

Key quality parameters, such as Acid Value and Peroxide Value, indicate the fuel's stability. If the oven overheats the sample, these values will artificially rise, leading to false data regarding the material's inherent quality.

Common Pitfalls to Avoid

The Risk of Overheating

It is tempting to increase the temperature to dry the fuel faster.

However, exceeding 80°C risks permanently damaging the oxidative stability of the biodiesel. This results in a fuel that goes rancid quickly during storage.

The Risk of Incomplete Drying

Conversely, failing to maintain the target temperature results in "wet" fuel.

Residual moisture can lead to microbial growth and engine corrosion. Trace alcohols remaining in the fuel can dangerously lower the fuel's flash point.

Ensuring Quality and Stability

To produce high-quality biodiesel, you must treat the drying phase as a precise chemical process, not just a heating step.

- If your primary focus is Process Safety: Ensure all trace alcohols are removed to maintain a safe flash point for storage and transport.

- If your primary focus is Quality Assurance: Strictly maintain the 80°C limit to prevent oxidation, ensuring your Acid and Peroxide Value tests accurately reflect the batch quality.

Precise thermal control during drying is the final safeguard that secures the chemical stability of your finished fuel.

Summary Table:

| Feature | Constant Temperature Oven | Vacuum Drying Oven |

|---|---|---|

| Mechanism | Convection heating at atmospheric pressure | Heating under reduced (negative) pressure |

| Target Temp | 80°C (Optimized for stability) | 80°C (Optimized for stability) |

| Boiling Point | Standard for water and alcohol | Lowered for faster evaporation |

| Primary Goal | Moisture & trace alcohol removal | Rapid moisture removal & volatile recovery |

| Key Benefit | Prevents thermal degradation | Faster processing with less oxidation risk |

Elevate Your Biodiesel Refining with KINTEK Precision

Don't compromise your fuel's chemical integrity with inconsistent heating. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum drying ovens and constant temperature systems designed to maintain the strict 80°C threshold required for moisture control. Whether you need standard lab equipment or customizable systems for unique refining needs, our solutions prevent oxidation and ensure accurate Acid and Peroxide Value results.

Ready to optimize your biodiesel quality assurance? Contact us today for a custom solution!

Visual Guide

References

- Roberto Ananias Ribeiro. Síntese e caracterização de ésteres metílicos obtidos com o uso do catalisador de CaO preparado por precipitação alcalina. DOI: 10.55905/cuadv17n5-073

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

People Also Ask

- What are the technical advantages of using an ALD system over PVD? Achieve Precise Ge:ZnO Thin Film Fabrication

- Why is a vacuum drying oven required for the pretreatment of modified zeolite? Preserve Pore Integrity for CO2 Capture

- What is the disadvantage of dental ceramic? Weighing Cost, Strength, and Aesthetics

- What is the function of a gas-phase catalytic reaction system? Evaluate Carbon-Metal Nanocomposites with Precision

- What advantages does a salt bath furnace offer for bainitic transformation? Achieve Superior Steel Microstructures

- What experimental conditions do physical property measurement systems provide for TaAs2? Explore Cryogenic Transport

- How does a high-precision temperature-controlled annealing furnace influence packaging steel microstructure?

- Why is high-purity nitrogen (N2) used in MSW pyrolysis? Secure Anaerobic Environments for Maximum Fuel Yield