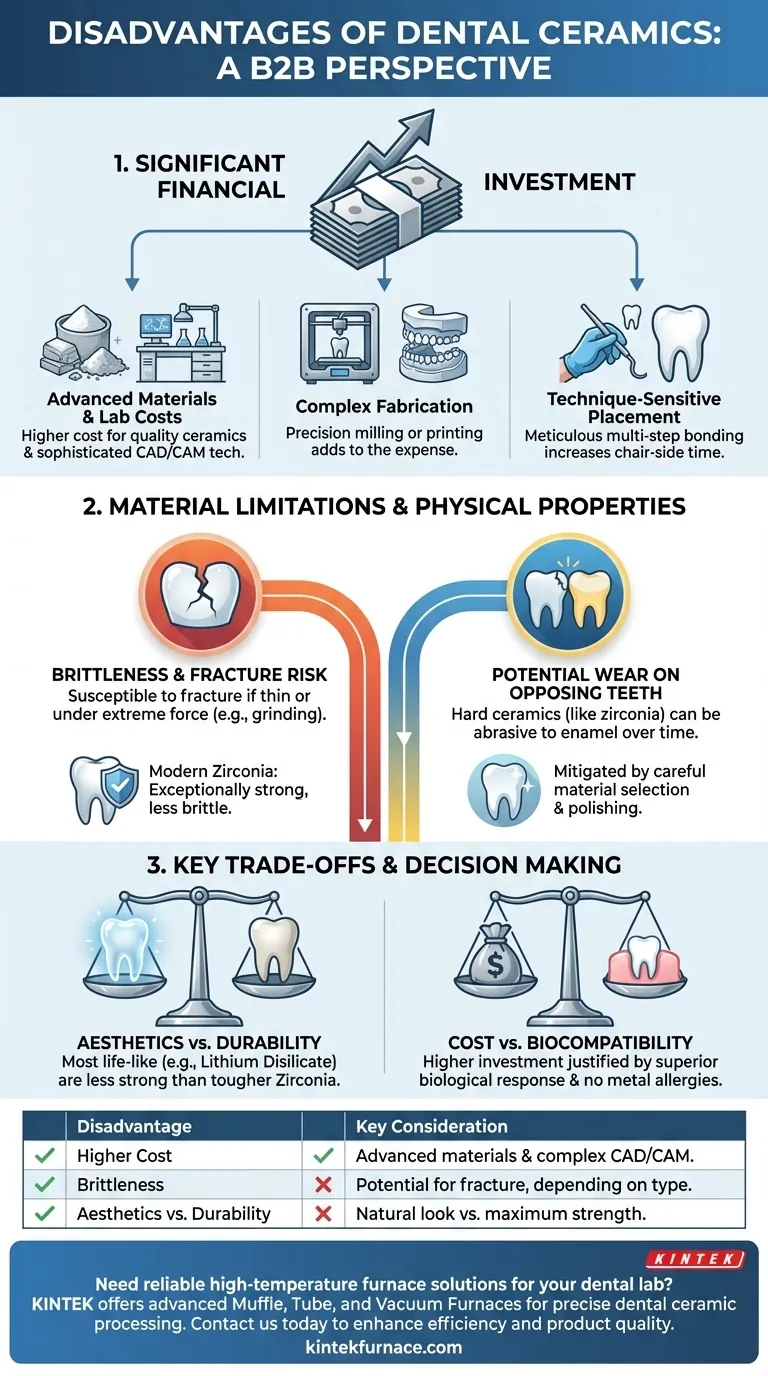

The primary disadvantage of dental ceramics is their higher cost compared to traditional options like porcelain-fused-to-metal restorations. This increased cost stems from more sophisticated materials and complex laboratory fabrication processes. Furthermore, while modern ceramics are incredibly strong, some types can be more brittle than their metal-based counterparts, creating a potential for fracture under extreme force.

While dental ceramics offer unparalleled aesthetics and biocompatibility, they represent a significant financial investment. The core challenge is not simply the cost, but understanding that different types of ceramics have different strengths, weaknesses, and ideal uses within the mouth.

The Core Disadvantage: Financial Investment

The most immediate and tangible drawback for any patient considering ceramic restorations is the price. This isn't arbitrary; it reflects the advanced technology and precision required to create them.

Why Ceramic Restorations Are More Expensive

The lab cost for a high-quality all-ceramic crown is significantly higher than for a traditional porcelain-fused-to-metal (PFM) crown. This is due to the price of the raw materials and the sophisticated CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) technology needed to mill or print the restoration with high precision.

The Impact of Chair-side Time

Placing a ceramic crown is often more technique-sensitive than cementing a PFM crown. Achieving a durable, long-lasting result requires a meticulous multi-step bonding process, which can take more of the dentist's time and expertise. This additional clinical time contributes to the overall higher cost passed on to the patient.

Understanding the Material Limitations

Beyond cost, it's critical to understand the physical properties of ceramics. The term "ceramic" covers a wide range of materials, from glass-like porcelains to high-strength zirconia, each with its own profile.

Brittleness and Fracture Risk

Ceramics are by nature more brittle than metals. While they have high compressive strength (resisting biting forces), they can be susceptible to fracture if the material is too thin or subjected to heavy, sharp forces. This is a primary concern for patients who clench or grind their teeth.

However, modern materials like monolithic zirconia are exceptionally strong and fracture-resistant, making them a superb choice for back teeth (molars) that endure the most force.

Potential Wear on Opposing Teeth

Some of the hardest ceramics, particularly certain types of zirconia, can be abrasive to the opposing natural tooth enamel over time. Dentists mitigate this by carefully selecting the right material and ensuring the bite is polished perfectly, but it remains a consideration in treatment planning.

Understanding the Trade-offs

Choosing a dental material is never about finding a "perfect" option, but about balancing competing priorities. Ceramics excel in some areas and require compromises in others.

Aesthetics vs. Durability

This is the central trade-off. The most beautiful, life-like ceramics (like feldspathic porcelain or lithium disilicate) are highly translucent, mimicking natural enamel perfectly. However, they are generally not as strong as the more opaque but tougher zirconia ceramics. The strongest materials may not be the first choice for a highly visible front tooth.

Cost vs. Biocompatibility

Ceramics are highly biocompatible, meaning they are inert and do not react with body tissues. This eliminates the risk of metal allergies or the dark line at the gumline that can sometimes appear with PFM crowns. For many, this superior biological and aesthetic outcome justifies the higher cost.

Making the Right Choice for Your Goal

The "best" material is entirely dependent on the location of the tooth and your personal priorities. Use this guide to facilitate a conversation with your dental professional.

- If your primary focus is aesthetics (e.g., for a front tooth): A highly translucent ceramic like lithium disilicate (e.g., E.max) is often the ideal choice, where its natural appearance is paramount.

- If your primary focus is strength (e.g., for a back molar): A solid, monolithic zirconia crown offers exceptional durability to withstand heavy chewing forces, making it a reliable long-term investment.

- If your primary focus is budget: A porcelain-fused-to-metal (PFM) crown remains a strong, reliable, and cost-effective option, though it involves a compromise on aesthetics and biocompatibility.

Understanding these key trade-offs empowers you to work with your dentist to select the solution that best aligns with your health, aesthetic goals, and budget.

Summary Table:

| Disadvantage | Key Consideration |

|---|---|

| Higher Cost | Due to advanced materials and complex CAD/CAM fabrication. |

| Brittleness | Potential for fracture under extreme force, depending on the ceramic type. |

| Aesthetics vs. Durability Trade-off | The most natural-looking ceramics may not be the strongest. |

Need a reliable partner for your dental lab's high-temperature furnace solutions? KINTEK understands that creating superior dental ceramics requires precise thermal processing. Our advanced Muffle, Tube, and Vacuum Furnaces, backed by deep customization capabilities, are engineered to meet the exacting demands of dental material processing, ensuring consistent results and durability. Contact us today to discuss how our solutions can enhance your lab's efficiency and product quality. Get in touch via our Contact Form

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow