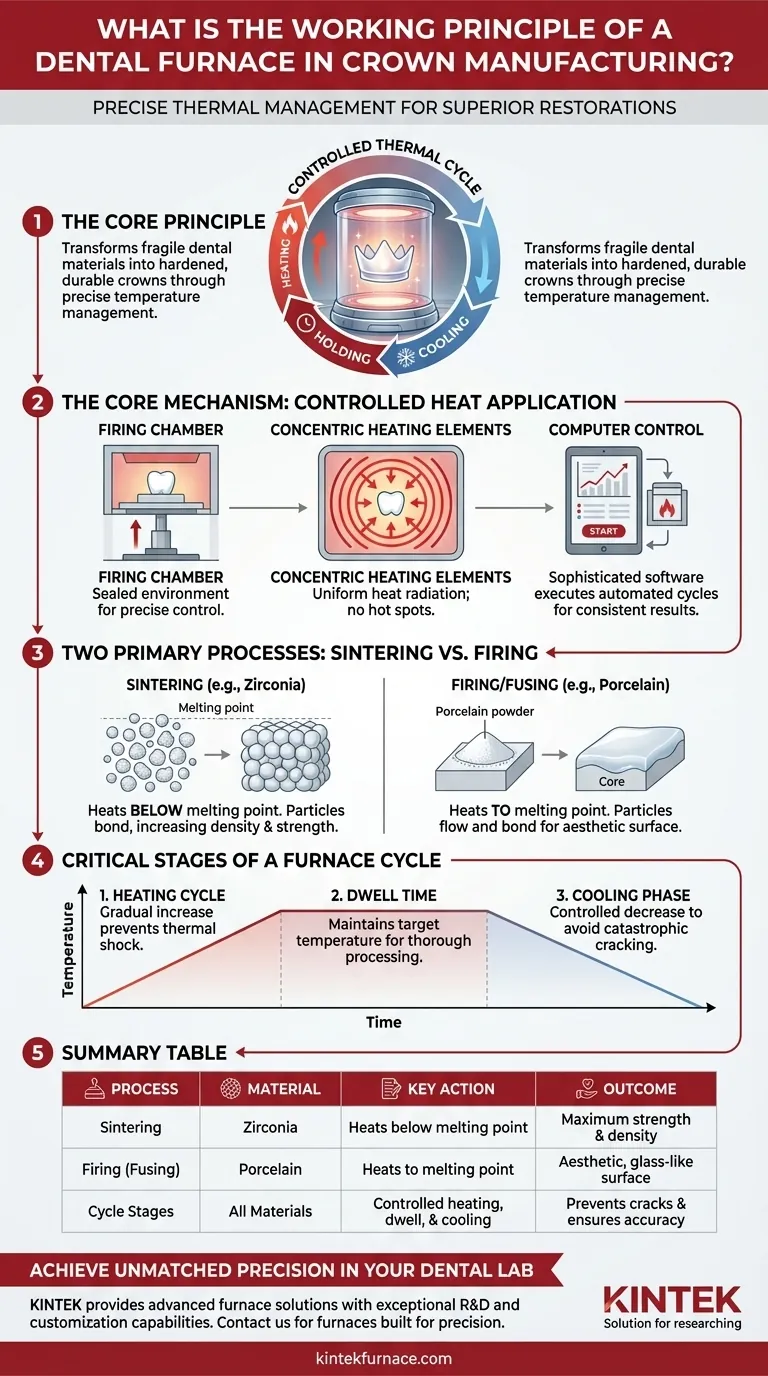

At its core, a dental furnace works by applying precise, high temperatures in a highly controlled environment. This process transforms dental materials like zirconia or porcelain from a fragile, pre-processed state into a hardened, durable, and dimensionally accurate final restoration, such as a crown.

The essential principle is not simply heating, but the precise management of a thermal cycle—heating, holding, and cooling—tailored to the specific material being used. This controlled process is what determines the final strength, fit, and aesthetics of the crown.

The Core Mechanism: Controlled Heat Application

A dental furnace is far more than a simple oven. Its design is centered around delivering uniform and predictable heat to a delicate dental restoration, ensuring a successful outcome without defects.

The Firing Chamber

The process begins by placing the crown on a firing platform. A motor-driven mechanism then seals the firing chamber, either by raising the platform into the furnace's upper housing or by lowering the housing over the platform. This creates an isolated environment for precise temperature control.

Concentric Heating Elements

Inside the chamber, heating coils are arranged concentrically, meaning they form circles around the restoration. This design ensures that heat is radiated evenly from all directions, preventing hot spots and ensuring the entire crown is processed uniformly.

The Role of Computer Control

Modern dental furnaces are managed by sophisticated software. A technician selects a program specific to the material being used, and the furnace executes the heating and cooling cycle automatically. This computerized control is critical for maintaining structural integrity and achieving consistent results.

Two Primary Processes: Sintering vs. Firing

While the term "furnace" is used broadly, it facilitates two fundamentally different thermal processes depending on the crown's material. Understanding this distinction is key.

The Principle of Sintering

Sintering is used for materials like zirconia. The process involves heating a powdered or porous material to a high temperature, but crucially, below its melting point.

This intense heat causes the individual particles to bond and fuse together, dramatically increasing the material's density and strength. Sintering transforms a chalky, oversized zirconia milling block into a solid, tough, and permanent restoration.

The Principle of Firing (Fusing)

Firing is the process used for porcelain. In this case, a mixture of porcelain powder is applied to a metal or ceramic core.

The furnace then heats the restoration to a temperature that melts the porcelain particles, causing them to flow together and chemically bond to the underlying substrate. This creates the smooth, glass-like surface and aesthetic qualities of a porcelain crown.

The Critical Stages of a Furnace Cycle

Regardless of the specific process, every furnace cycle follows a controlled, multi-stage path to ensure the crown's success.

1. The Heating Cycle

The temperature inside the furnace is never raised instantly. It ramps up gradually according to the material's specific program. This slow increase prevents thermal shock, which could cause the delicate restoration to crack or warp.

2. The Dwell Time

Once the target temperature is reached, the furnace holds it there for a prescribed period. This "dwell time" ensures the heat fully penetrates the material, allowing the sintering or firing process to complete thoroughly.

3. The Cooling Phase

Just as important as heating, the cooling phase is slow and controlled. Opening the chamber too soon would expose the superheated crown to room temperature air, causing catastrophic cracking. The furnace cools down gradually, allowing the material to stabilize.

Making the Right Choice for Your Goal

The furnace's working principle is directly tied to the desired outcome for the final restoration.

- If your primary focus is maximum strength with monolithic materials: You will rely on a sintering furnace to densify materials like zirconia without melting them.

- If your primary focus is aesthetics with layered restorations: You will use a firing process to melt and fuse layers of porcelain onto a core substrate.

Ultimately, the dental furnace's principle is to precisely manage thermal energy to unlock the specific physical and aesthetic properties required of the final dental crown.

Summary Table:

| Process | Material | Key Action | Outcome |

|---|---|---|---|

| Sintering | Zirconia | Heats below melting point | Fuses particles for maximum strength & density |

| Firing (Fusing) | Porcelain | Heats to melting point | Melts particles for aesthetic, glass-like surface |

| Cycle Stages | All Materials | Controlled heating, dwell, & cooling | Prevents cracks & ensures dimensional accuracy |

Achieve Unmatched Precision in Your Dental Lab

Just as precise thermal control is critical for a perfect crown, having the right high-temperature equipment is foundational to your lab's success. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced furnace solutions.

Our product line, including Muffle, Tube, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities. Whether you need a furnace tailored for specific dental material cycles or unique experimental requirements, we can deliver a solution that ensures consistent, reliable results.

Ready to enhance your lab's capabilities with a furnace built for precision? Contact our experts today to discuss your specific needs.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations