Using a single, universal setting for all materials in your dental furnace is a critical mistake because it disregards the unique chemical and physical properties inherent to each material. This "one-size-fits-all" approach fundamentally compromises the quality of the final restoration, leading to issues with strength, aesthetics, and fit. The correct approach is to meticulously follow the sintering parameters provided by the material's manufacturer.

The quality of a dental restoration is not determined by the furnace alone, but by the precise synergy between the material's specific requirements and the furnace's ability to execute them. Ignoring the manufacturer's instructions is a direct path to unpredictable and inferior clinical outcomes.

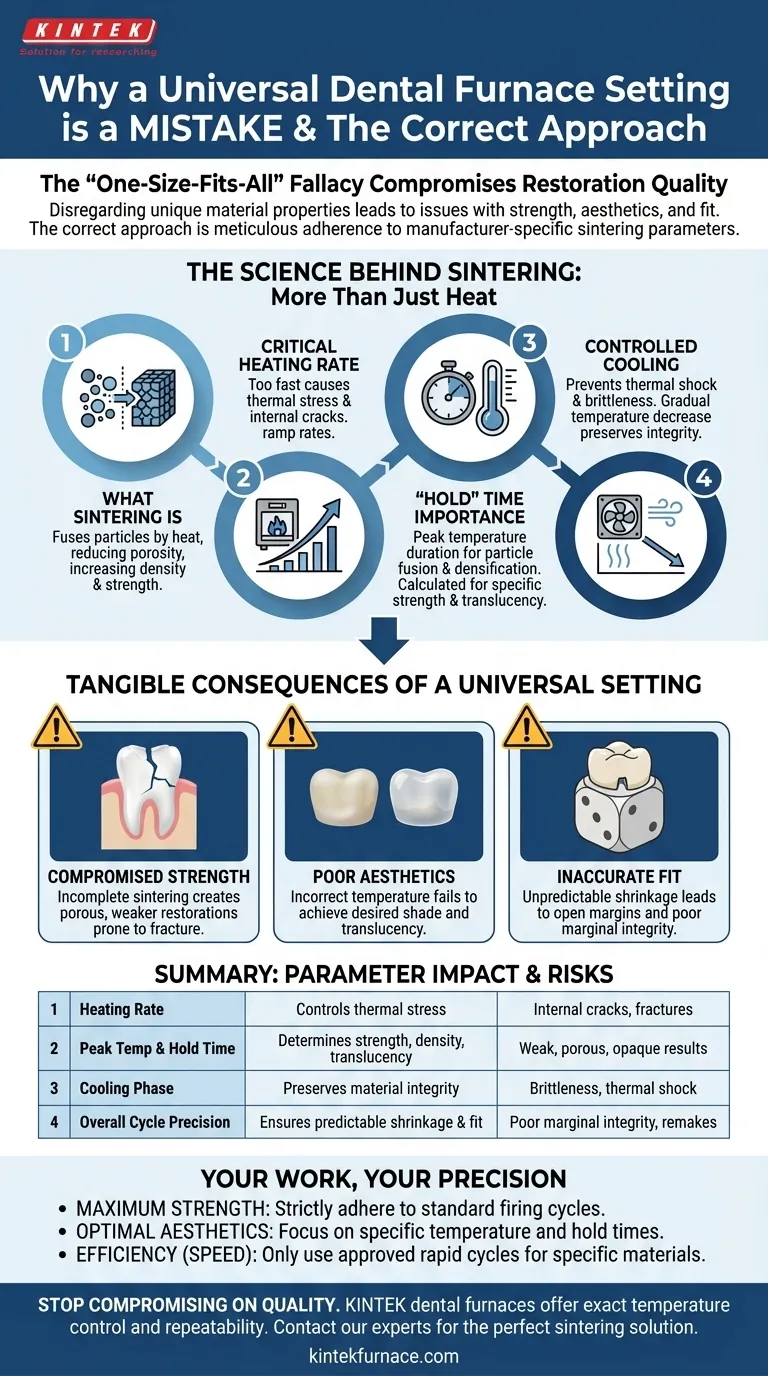

The Science Behind Sintering: More Than Just Heat

To understand why a universal setting fails, you must first appreciate that sintering is a highly controlled scientific process, not just a simple heating cycle. Each phase is engineered to achieve a specific outcome at the microscopic level.

What Sintering Actually Is

Sintering is the process of compacting and forming a solid mass of material by heat, without melting it to the point of liquefaction. For dental materials like zirconia, this process fuses the individual particles, reducing porosity and dramatically increasing density and strength.

The Critical Role of the Heating Rate

The rate at which the furnace temperature increases is crucial. Heating a material too quickly can introduce thermal stress, leading to internal cracks or fractures. Different materials, especially those with varying thicknesses, require different ramp rates to heat uniformly.

The Importance of 'Hold' Time

The "hold" or "dwell" time is the period when the furnace maintains its peak temperature. This is when the most critical particle fusion and densification occur. This duration is precisely calculated by the manufacturer based on the material's specific composition to achieve its target strength and translucency.

The Cooling Phase: A Frequently Overlooked Step

Controlled cooling is just as important as heating. Cooling a restoration too rapidly can cause thermal shock, making the final product brittle and prone to fracture. The manufacturer’s protocol ensures a gradual temperature decrease that preserves the material's integrity.

The Tangible Consequences of a Universal Setting

When you ignore material-specific guidelines, the resulting failures are not theoretical. They manifest as tangible problems that can lead to costly remakes and a loss of clinical trust.

Compromised Strength and Durability

The most significant risk is a weaker restoration. Incomplete sintering results in a more porous material that has not reached its specified flexural strength. This restoration is far more likely to fracture under normal occlusal loads in the patient's mouth.

Poor Aesthetics and Translucency

Sintering temperature directly impacts the final shade and translucency of materials like zirconia. A setting that is too low or too high can result in a restoration that is opaque, "dead" in appearance, or fails to match the desired shade, which is particularly disastrous for anterior cases.

Inaccurate Fit and Marginal Integrity

All-ceramic materials are designed to shrink a precise amount during sintering. A universal program that deviates from the specified heating rate and hold time will cause unpredictable shrinkage. This leads to poor-fitting restorations, open margins, and an increased risk of secondary caries.

Understanding the Trade-offs: Speed vs. Quality

The primary motivation for using a single, simplified setting is often a desire for speed and efficiency. While understandable, this approach introduces unacceptable risks.

The Lure of Speed Sintering Cycles

Many modern materials and furnaces offer "speed" or "fast" sintering cycles. These are highly appealing in a busy lab or clinic. However, these cycles are not universal; they are engineered for a specific material that has been validated for rapid heating.

When Speed Comes at a Cost

Using a generic fast cycle on a material not designed for it is a recipe for failure. You may save an hour in the furnace, but you risk creating a weak or aesthetically flawed restoration that requires a complete remake, negating any time saved.

The Myth of the "Universal" Program

A true "universal" program that delivers optimal results for all materials does not exist. It is a compromise that sacrifices the unique properties of each material for the sake of convenience. High-quality work demands precision, not approximation.

How to Apply This to Your Work

Your protocol should be built around precision and predictability. By tailoring the furnace cycle to the material, you take control of the outcome.

- If your primary focus is maximum strength and longevity: Strictly adhere to the manufacturer's recommended standard firing cycle for that specific material.

- If your primary focus is optimal aesthetics for anterior cases: Pay close attention to the specific temperature and hold times designed to achieve the desired translucency.

- If your primary focus is efficiency: Only use a rapid sintering cycle if both the material manufacturer and the furnace manufacturer explicitly approve it for that exact combination.

Ultimately, treating each material with the precision it requires is the foundation of high-quality, reliable dental restorations.

Summary Table:

| Sintering Parameter | Impact on Restoration | Risk of Universal Setting |

|---|---|---|

| Heating Rate | Controls thermal stress and uniformity | Internal cracks, fractures |

| Peak Temperature & Hold Time | Determines strength, density, and translucency | Weak, porous, or opaque results |

| Cooling Phase | Preserves material integrity | Brittleness, thermal shock |

| Overall Cycle Precision | Ensures predictable shrinkage and fit | Poor marginal integrity, remakes |

Stop compromising on restoration quality. Your materials deserve precision. At KINTEK, we understand that every dental ceramic and zirconia has unique sintering needs. Our advanced laboratory furnaces are engineered for exact temperature control and repeatability, ensuring you can consistently follow manufacturer protocols for flawless strength and aesthetics.

Let us help you achieve predictable, high-quality results every time. Contact our dental furnace experts today to find the perfect sintering solution for your lab's specific materials and workflows.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations