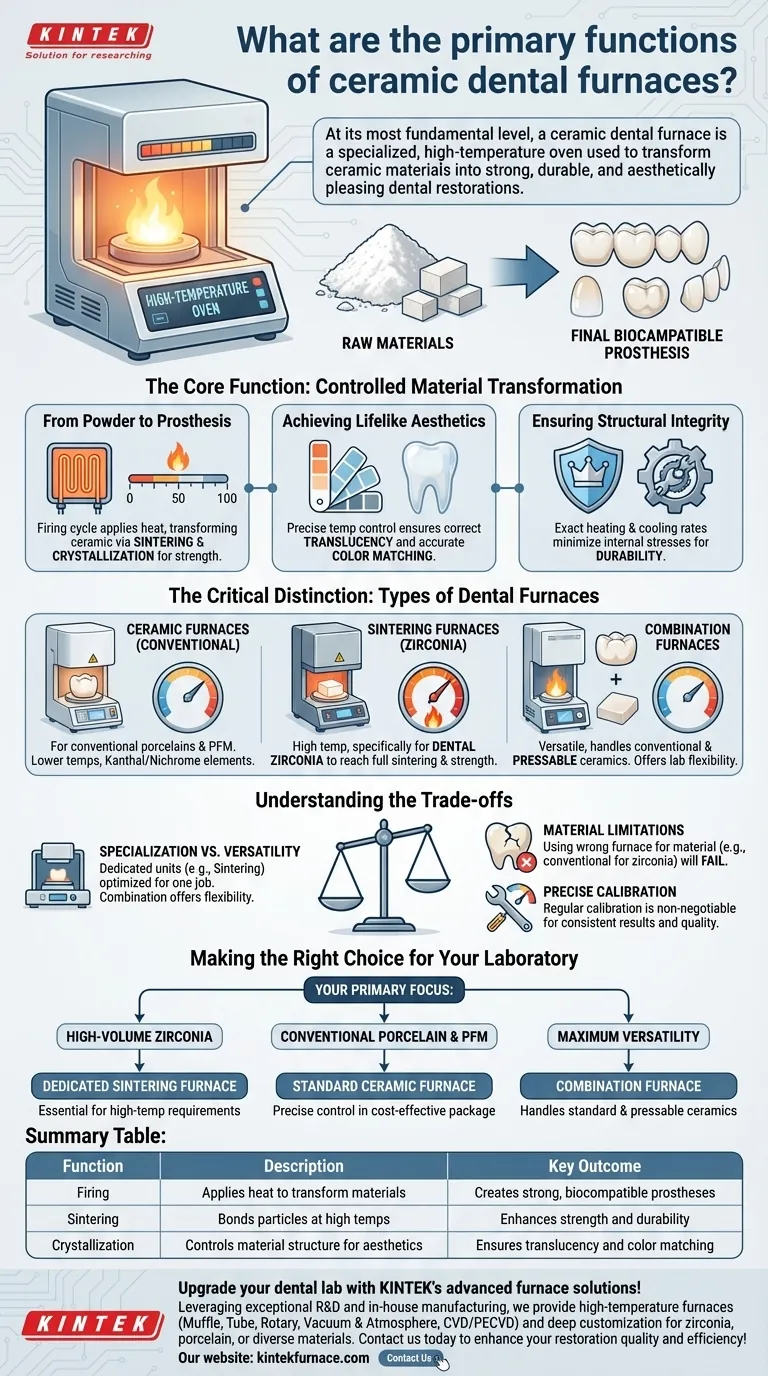

At its most fundamental level, a ceramic dental furnace is a specialized, high-temperature oven used to transform ceramic materials into strong, durable, and aesthetically pleasing dental restorations. Its primary functions are to fire, sinter, or crystallize materials like porcelain and zirconia, turning them from a raw or partially processed state into a final, biocompatible prosthesis such as a crown, bridge, or veneer.

A dental furnace is not simply a source of heat; it is a precision instrument for material science. Its core purpose is to execute highly specific temperature programs that control the physical and aesthetic properties of the final dental restoration.

The Core Function: Controlled Material Transformation

A dental furnace's value lies in its ability to precisely manage heat over time. This controlled process is what gives dental ceramics their necessary characteristics for clinical success.

From Powder to Prosthesis

The furnace applies heat according to a pre-programmed schedule. This process, known as a firing cycle, transforms the ceramic material by creating bonds between particles, a process called sintering or crystallization. This solidifies the restoration and gives it its final strength.

Achieving Lifelike Aesthetics

The firing cycle is critical for achieving the desired esthetics. Precise temperature control ensures the proper level of translucency and allows for accurate color matching, making the restoration indistinguishable from natural teeth.

Ensuring Structural Integrity

By following exact heating and cooling rates, the furnace minimizes internal stresses within the ceramic. This process guarantees the strength and durability required for a long-lasting restoration that can withstand the forces of chewing.

The Critical Distinction: Types of Dental Furnaces

Not all dental furnaces are the same. They are specialized based on the materials they are designed to process, primarily distinguished by their maximum temperature capabilities.

Ceramic Furnaces (Conventional)

These are the most common type, designed for firing conventional porcelains. They are used for all-metal-free restorations and porcelain-fused-to-metal (PFM) crowns. These furnaces operate at lower temperatures and often use heating elements made of Kanthal or Nichrome.

Sintering Furnaces (Zirconia)

These are high-temperature furnaces built specifically for processing dental zirconia. Zirconia requires much higher temperatures to achieve full sintering and reach its maximum strength, a task conventional ceramic furnaces cannot perform.

Combination Furnaces

As the name implies, these versatile units are designed to handle multiple tasks. They can typically fire conventional ceramics and also manage the process for pressable ceramics, offering greater flexibility for laboratories that work with a wide range of materials.

Understanding the Trade-offs

Choosing and operating a dental furnace involves balancing specialization, versatility, and operational requirements. Misunderstanding these trade-offs can lead to failed restorations and inefficient workflows.

Specialization vs. Versatility

A dedicated sintering furnace is optimized for one job—processing zirconia—and does it exceptionally well. A combination furnace offers flexibility but may not have the same capacity or specific features as a dedicated unit. The choice depends entirely on the lab's primary workload.

Critical Material Limitations

The most significant pitfall is attempting to process a material in the wrong type of furnace. Using a conventional ceramic furnace for zirconia will not work, as it cannot reach the required sintering temperatures, resulting in a weak, chalky, and unusable restoration.

The Need for Precise Calibration

Because outcomes are entirely dependent on temperature accuracy, regular maintenance and calibration are non-negotiable. An uncalibrated furnace will produce inconsistent results, leading to weak or aesthetically flawed restorations, wasted materials, and lost time.

Making the Right Choice for Your Laboratory

Selecting the correct furnace is a foundational investment that impacts the quality and efficiency of your lab's output. Your decision should be guided by the primary materials you work with.

- If your primary focus is high-volume zirconia production: A dedicated sintering furnace is essential to meet the material's high-temperature requirements efficiently.

- If your primary focus is conventional porcelain and PFM restorations: A standard ceramic furnace provides the precise control needed for these materials in a cost-effective package.

- If your laboratory requires maximum versatility for various materials: A combination furnace that can handle both standard firing and pressable ceramics is the ideal choice.

Ultimately, selecting the right furnace is a foundational decision that directly dictates the quality, efficiency, and range of services your dental laboratory can provide.

Summary Table:

| Function | Description | Key Outcome |

|---|---|---|

| Firing | Applies heat to transform ceramic materials | Creates strong, biocompatible prostheses |

| Sintering | Bonds particles at high temperatures | Enhances strength and durability |

| Crystallization | Controls material structure for aesthetics | Ensures translucency and color matching |

Upgrade your dental lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique needs, whether you specialize in zirconia, porcelain, or diverse materials. Contact us today to enhance your restoration quality and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the benefits of using dental sintering and porcelain furnaces? Enhance Strength, Aesthetics, and Efficiency

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision