At its core, a dental furnace is the essential tool that transforms fragile, pre-fabricated ceramic materials into strong, durable, and aesthetically pleasing dental restorations. Without the precise heating processes these furnaces provide, materials like zirconia and porcelain would lack the structural integrity to withstand the forces of chewing, making modern restorative dentistry impossible.

The true importance of a dental furnace is not just its ability to generate heat, but its capacity for precise control. It governs the transformation of a restoration's material properties, directly impacting its final strength, fit, and aesthetic quality.

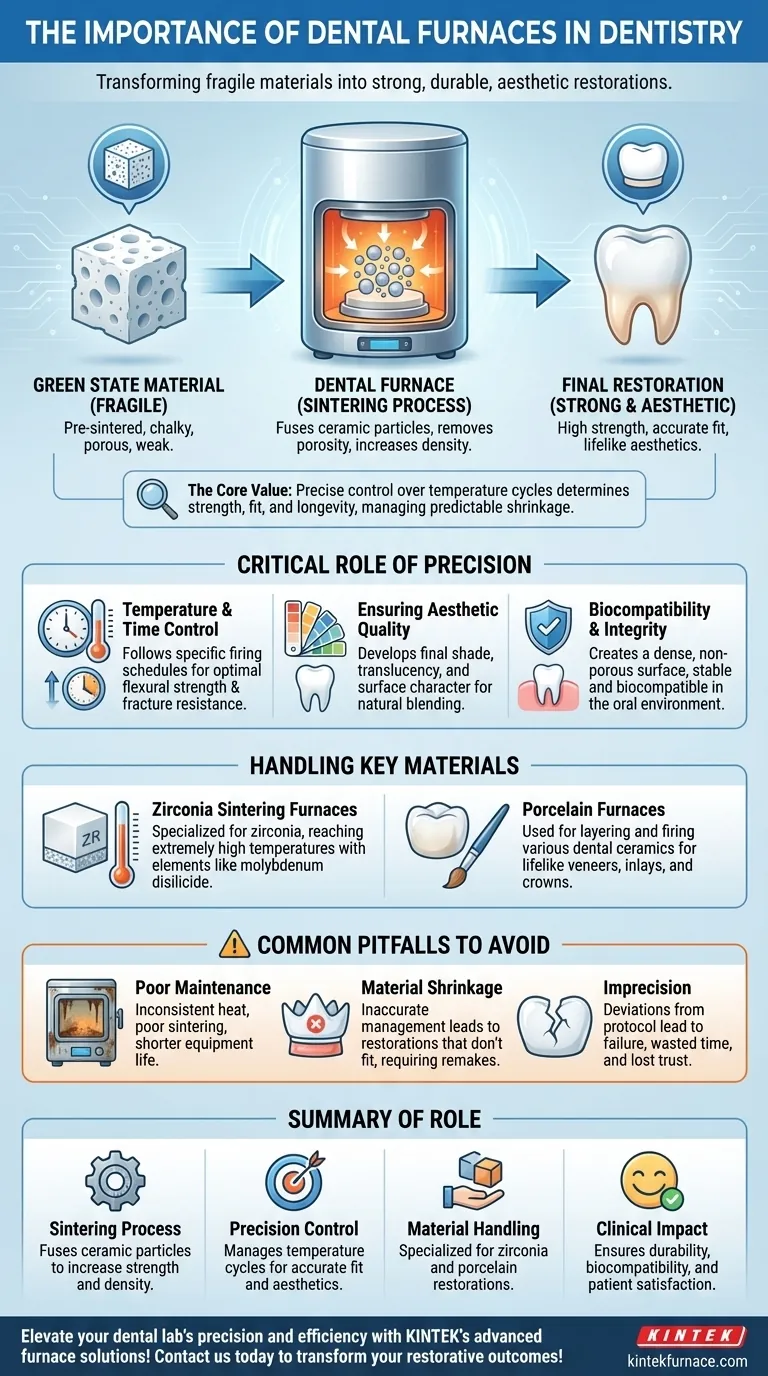

From Fragile Material to Final Restoration

A dental restoration, such as a crown or bridge, is often milled from a block of ceramic material in a pre-sintered or "green" state. In this form, it is chalky, porous, and too weak for clinical use. The dental furnace is what completes the manufacturing process.

The Core Process: Sintering

Sintering is a high-temperature process that fuses the ceramic particles together. This compacts the material, removes porosity, and dramatically increases its density and strength.

During sintering, the material undergoes significant and predictable shrinkage. A key function of the furnace and its programming is to manage this shrinkage to ensure the final restoration fits the patient perfectly.

The Impact on Clinical Outcomes

The furnace's performance directly affects the quality of the final product. Precise control over the heating and cooling cycles is what determines the strength, accuracy of fit, and longevity of the restoration.

An improperly fired restoration can be brittle, fit poorly, or have a compromised aesthetic, leading to clinical failure.

Handling Key Materials: Zirconia and Porcelain

Different furnaces are designed for specific materials. Sintering furnaces are primarily used for zirconia, using specialized heating elements (like molybdenum disilicide) to reach the extremely high temperatures required to harden it.

Porcelain furnaces are used for layering and firing various dental ceramics to create veneers, inlays, and crowns with lifelike aesthetics.

The Critical Role of Precision

A simple oven cannot replace a dental furnace. The value lies in its ability to execute complex, pre-programmed temperature cycles with exceptional accuracy.

Temperature and Time Control

Each ceramic material has a specific firing schedule recommended by the manufacturer. Following this schedule precisely is critical for achieving the desired material properties, including flexural strength and fracture resistance.

Ensuring Aesthetic Quality

The firing process is what brings a restoration to life. It develops the material's final shade, translucency, and surface character, ensuring it blends seamlessly with the patient's natural teeth.

Biocompatibility and Integrity

Proper sintering creates a dense, non-porous surface. This makes the final restoration biocompatible, stable, and resistant to wear and staining in the oral environment.

Common Pitfalls to Avoid

While indispensable, a dental furnace is a precision instrument that requires proper management. Overlooking its operational needs can compromise the quality of your work.

The Cost of Poor Maintenance

Routine maintenance is not optional. A dirty furnace with corroded heating elements cannot deliver consistent heat, leading to poor-quality sintering and a shorter lifespan for the equipment itself.

The Challenge of Material Shrinkage

If a furnace is not properly calibrated, it cannot accurately manage the material's shrinkage. This is a primary cause of restorations that are too small and do not fit, requiring costly and time-consuming remakes.

The Consequence of Imprecision

Ultimately, any deviation from the correct firing protocol introduces a variable that can lead to failure. This results in wasted chair time, lost material costs, and a breakdown of trust with the patient and clinician.

Applying This to Your Laboratory's Goal

Your choice and use of a dental furnace should align directly with the services you provide.

- If your primary focus is creating high-strength zirconia crowns and bridges: A dedicated sintering furnace capable of reaching and holding precise high temperatures is non-negotiable for achieving the required durability.

- If your primary focus is producing highly aesthetic veneers and inlays: A porcelain furnace with immaculate temperature control is essential for managing shade, translucency, and the perfect fit of delicate restorations.

- If your primary focus is ensuring long-term practice efficiency: Implementing a strict furnace calibration and maintenance schedule is the most effective way to guarantee consistent quality and prevent costly failures.

The dental furnace is the cornerstone of quality and consistency in modern restorative dentistry.

Summary Table:

| Aspect | Role in Dentistry |

|---|---|

| Sintering Process | Fuses ceramic particles to increase strength and density. |

| Precision Control | Manages temperature cycles for accurate fit and aesthetics. |

| Material Handling | Specialized for zirconia and porcelain restorations. |

| Clinical Impact | Ensures durability, biocompatibility, and patient satisfaction. |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide sintering and porcelain furnaces tailored for zirconia crowns, bridges, veneers, and more. Our deep customization capabilities ensure your unique experimental needs are met, reducing remakes and boosting trust with clinicians. Contact us today to discuss how our high-temperature furnace line can transform your restorative outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns