In short, accurate temperature control is the single most critical factor in determining the success or failure of a dental restoration. Without it, the physical, aesthetic, and structural properties of materials like porcelain and zirconia become unpredictable, leading directly to clinical failures, costly remakes, and compromised patient care.

A dental furnace is not merely an oven; it is a precision instrument. Deviations in temperature are not minor inconsistencies—they are fundamental errors that undermine the science of the materials, transforming a high-performance restoration into a liability.

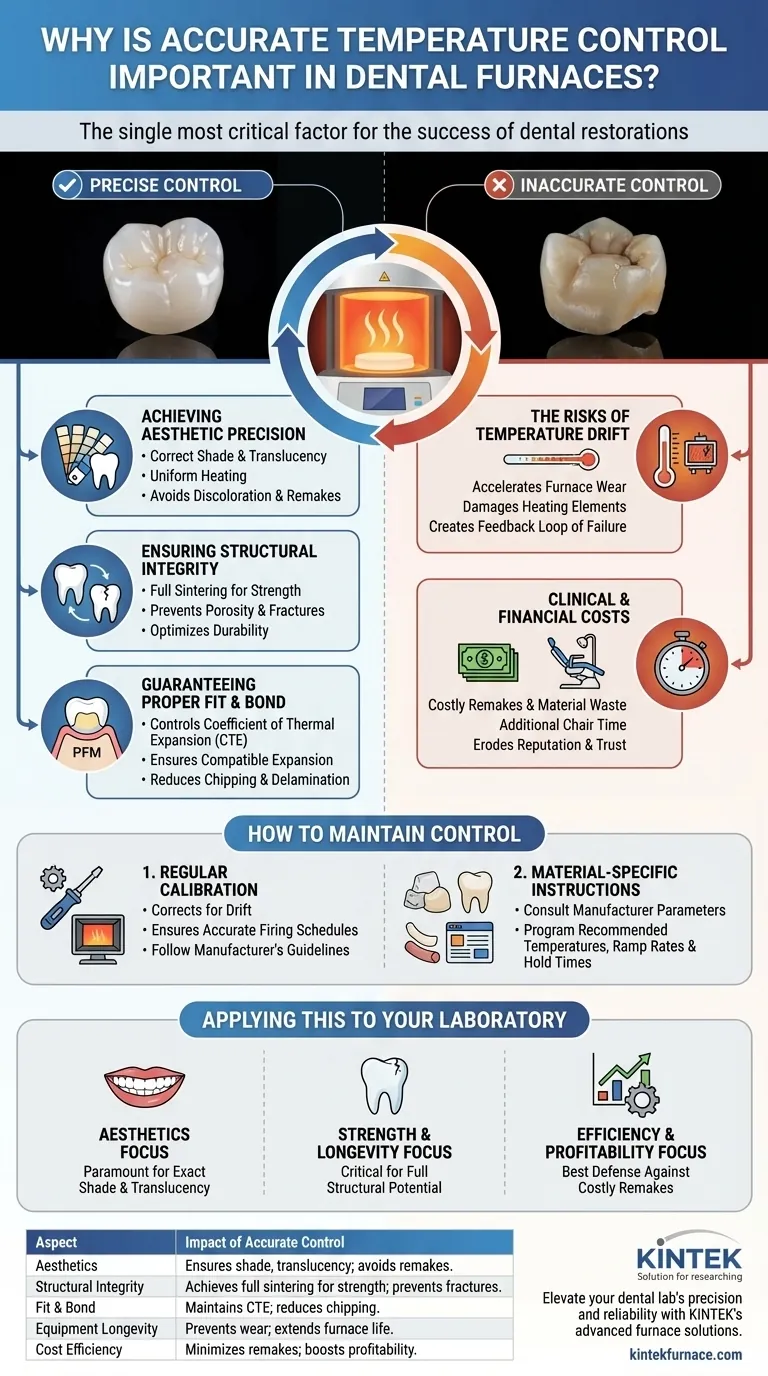

The Impact on Final Restoration Quality

The firing or sintering cycle is a carefully choreographed process where temperature transforms powders into a strong, monolithic structure. Even slight inaccuracies can have a cascading effect on the final outcome.

Achieving Aesthetic Precision

Precise temperature control ensures the porcelain or zirconia powder is heated uniformly. This is essential for achieving the correct shade and translucency.

Inconsistent heating can result in restorations that are opaque, discolored, or fail to match the shade guide, requiring a complete remake.

Ensuring Structural Integrity

The strength, durability, and fracture resistance of a restoration are developed at specific temperatures. This process, known as sintering, must be exact.

If the temperature is too low, the material will not be fully sintered, leaving it weak and porous. If it is too high, it can cause grain growth or distortion, also compromising strength and leading to premature fractures in the mouth.

Guaranteeing a Proper Fit and Bond

The Coefficient of Thermal Expansion (CTE) is a critical property, especially for porcelain-fused-to-metal (PFM) restorations. The firing process must be controlled to ensure the porcelain and the metal framework expand and contract compatibly.

Incorrect temperatures can alter the CTE, creating stress at the bond interface that results in chipping, cracking, or complete delamination of the porcelain from its substructure.

The Hidden Risks of Temperature Drift

Inaccuracy is not just a one-time problem. It creates a cycle of escalating issues that affect both the restorations and the equipment itself.

The Vicious Cycle of Furnace Wear

Operating a furnace outside of its ideal temperature range doesn't just ruin the restoration—it damages the furnace. Improper temperatures cause accelerated wear on heating elements and insulation.

This damage, in turn, makes the furnace less able to hold a stable temperature, creating a feedback loop of increasingly inaccurate results and eventual equipment failure.

The Clinical and Financial Cost of Failure

Every failed restoration has a cost. This includes the wasted materials and technician time for the remake, but more importantly, the additional chair time for the dentist and the inconvenience to the patient.

Ultimately, inconsistent quality erodes the reputation of the dental laboratory and the trust of its clinical partners.

The Pitfall of Skipping Calibration

Furnaces drift over time. Relying on factory settings or an old firing schedule without regular verification is a significant risk.

Calibration is the only way to ensure that the temperature displayed on the screen matches the actual temperature inside the chamber. Neglecting it is equivalent to working with an unverified and unreliable instrument.

How to Maintain Control

Achieving consistent, high-quality results is dependent on a disciplined, systematic approach to temperature management.

The Non-Negotiable Step: Regular Calibration

Calibration is the process of adjusting the furnace's temperature controller to match a known, verified standard. This should be performed routinely according to the manufacturer's guidelines.

This single action corrects for temperature drift from aging components and ensures your firing schedules are accurate and repeatable.

Following Material-Specific Instructions

Never assume one firing program works for all materials. Each ceramic, zirconia, or porcelain system has a unique firing schedule developed by its manufacturer.

Always consult and precisely program the manufacturer's recommended temperatures, ramp rates, and hold times for the specific material you are using.

Applying This to Your Laboratory

Your approach to temperature control should be dictated by your highest priority, whether it is aesthetics, longevity, or operational efficiency.

- If your primary focus is aesthetics: Absolute temperature accuracy is paramount for hitting the exact shade and translucency that dentists and patients demand.

- If your primary focus is strength and longevity: Adhering to precise sintering temperatures is critical to guarantee the material's full structural potential and prevent clinical fractures.

- If your primary focus is efficiency and profitability: Strict temperature control and regular calibration are your best defense against costly remakes, wasted materials, and lost time.

Mastering temperature control is mastering the predictability and quality of your final restorations.

Summary Table:

| Aspect | Impact of Accurate Temperature Control |

|---|---|

| Aesthetics | Ensures correct shade and translucency, avoiding discoloration and remakes |

| Structural Integrity | Achieves full sintering for strength and durability, preventing fractures |

| Fit and Bond | Maintains proper CTE for compatibility, reducing chipping and delamination |

| Equipment Longevity | Prevents wear on heating elements and insulation, extending furnace life |

| Cost Efficiency | Minimizes remakes, wasted materials, and chair time, boosting profitability |

Elevate your dental lab's precision and reliability with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Ensure flawless restorations and boost efficiency—contact us today to discuss how we can support your success!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision