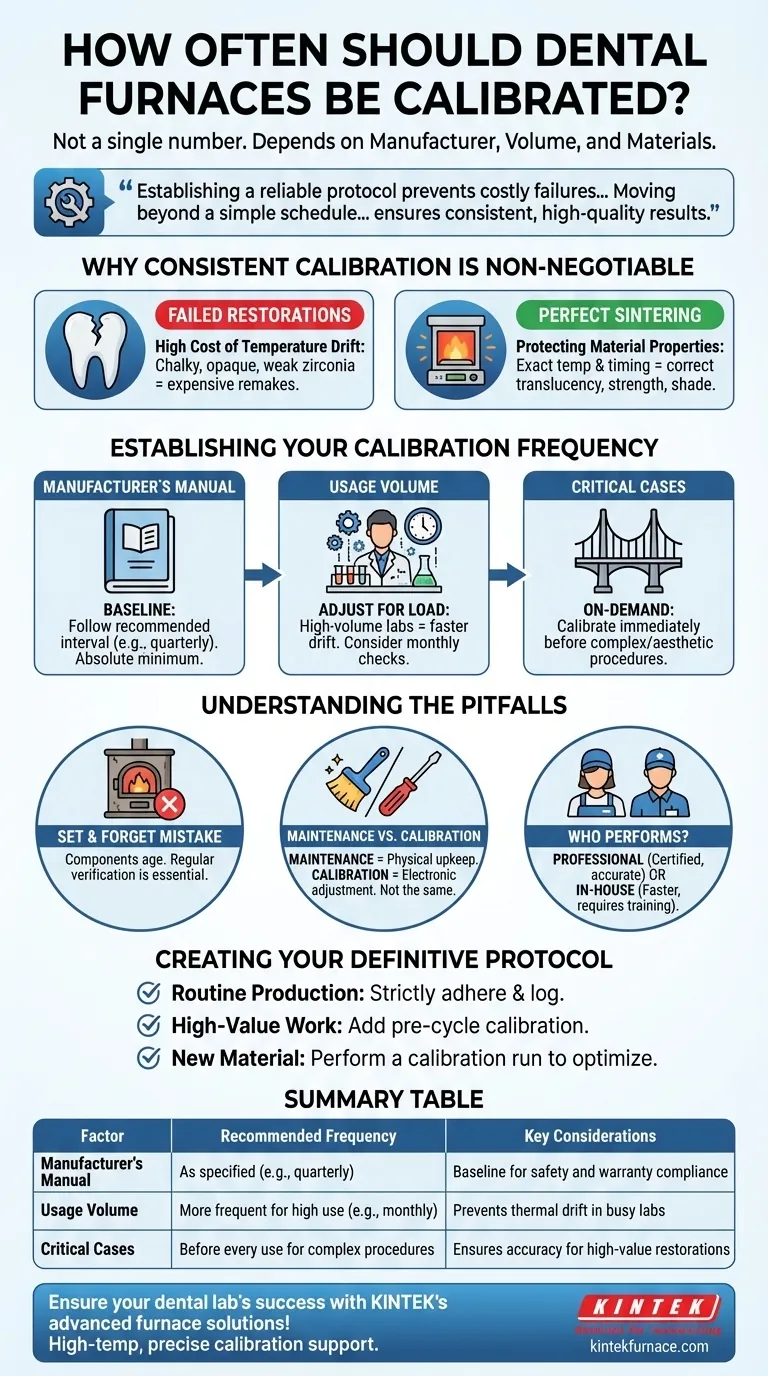

The correct calibration frequency for a dental furnace is not a single, universal number. While some intricate procedures demand calibration before every use, the standard for most labs is to follow a regular schedule. This schedule is primarily dictated by the furnace manufacturer's recommendations, the volume of use, and the types of materials being processed.

Your core challenge isn't just knowing when to calibrate, but establishing a reliable protocol that prevents costly failures. Moving beyond a simple schedule to a risk-based approach ensures consistent, high-quality results for every restoration.

Why Consistent Calibration is Non-Negotiable

A dental furnace is a precision instrument. Assuming it maintains its accuracy over time is a significant financial and reputational risk.

The High Cost of Temperature Drift

Even a slight deviation from the target temperature can compromise the structural integrity and aesthetic qualities of a dental restoration. Inaccurate heating can lead to chalky, opaque, or weak zirconia, resulting in failed restorations and expensive remakes.

Protecting Material Properties

Sintering is a delicate thermal process. Correct calibration ensures that the furnace's temperature and timing are exact, which is critical for achieving the specified translucency, strength, and shade for modern dental materials.

Establishing Your Calibration Frequency

A reliable calibration protocol is built on three key factors: the manufacturer's baseline, your usage patterns, and the clinical demands of the case.

Start with the Manufacturer's Manual

Your furnace's user manual is the definitive starting point. The manufacturer has tested the equipment extensively and provides a recommended calibration interval based on its design and components. Adhering to this is the absolute minimum requirement.

Calibrate Based on Usage Volume

A high-volume lab running its furnaces continuously will experience thermal drift faster than a small lab with infrequent use. If your furnace is a workhorse, consider a more frequent schedule than the manufacturer's minimum, such as monthly checks.

Calibrate "On-Demand" for Critical Cases

For highly complex or aesthetically demanding procedures, such as large-span bridges or anterior veneers, calibrating immediately before the firing cycle is a best practice. This eliminates temperature inaccuracy as a variable and ensures the best possible outcome for high-value work.

Understanding the Pitfalls

Simply owning a furnace isn't enough. Avoiding common misunderstandings about its upkeep is crucial for long-term success.

The "Set and Forget" Mistake

Calibration is not a one-time event. Heating elements age, thermocouples degrade, and electronics can drift. Regular verification is the only way to ensure the temperature displayed on the screen matches the actual temperature inside the chamber.

Confusing Maintenance with Calibration

Routine maintenance and calibration are two different tasks.

- Maintenance involves physical upkeep: cleaning the chamber, inspecting heating elements for wear, and ensuring seals are intact.

- Calibration is an electronic adjustment that aligns the furnace's internal thermometer (thermocouple) with a known, accurate temperature standard.

Deciding Who Performs the Calibration

You have two primary options: professional service or in-house calibration. A manufacturer's technician provides a certified and highly accurate service but involves cost and potential downtime. Performing it in-house is faster but requires proper training and equipment to be effective.

Creating Your Definitive Calibration Protocol

To ensure predictability and excellence in your restorations, implement a clear protocol based on your lab's specific operational needs.

- If your primary focus is routine, high-volume production: Strictly adhere to the manufacturer's recommended schedule and meticulously log every calibration event.

- If your primary focus is high-value aesthetic and complex restorative work: Calibrate before every critical sintering cycle in addition to your regularly scheduled verifications.

- If you are introducing a new material to your workflow: Perform a calibration run to ensure your furnace's program is perfectly optimized for that specific material's requirements.

A disciplined approach to calibration transforms your furnace from a potential point of failure into your most reliable production asset.

Summary Table:

| Factor | Recommended Frequency | Key Considerations |

|---|---|---|

| Manufacturer's Manual | As specified (e.g., quarterly) | Baseline for safety and warranty compliance |

| Usage Volume | More frequent for high use (e.g., monthly) | Prevents thermal drift in busy labs |

| Critical Cases | Before every use for complex procedures | Ensures accuracy for high-value restorations |

Ensure your dental lab's success with KINTEK's advanced furnace solutions! We specialize in high-temperature furnaces tailored for dental applications, offering precise calibration support and deep customization to meet your unique material and production needs. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. Don't let calibration issues compromise your restorations—contact us today to learn how we can enhance your lab's reliability and efficiency!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations