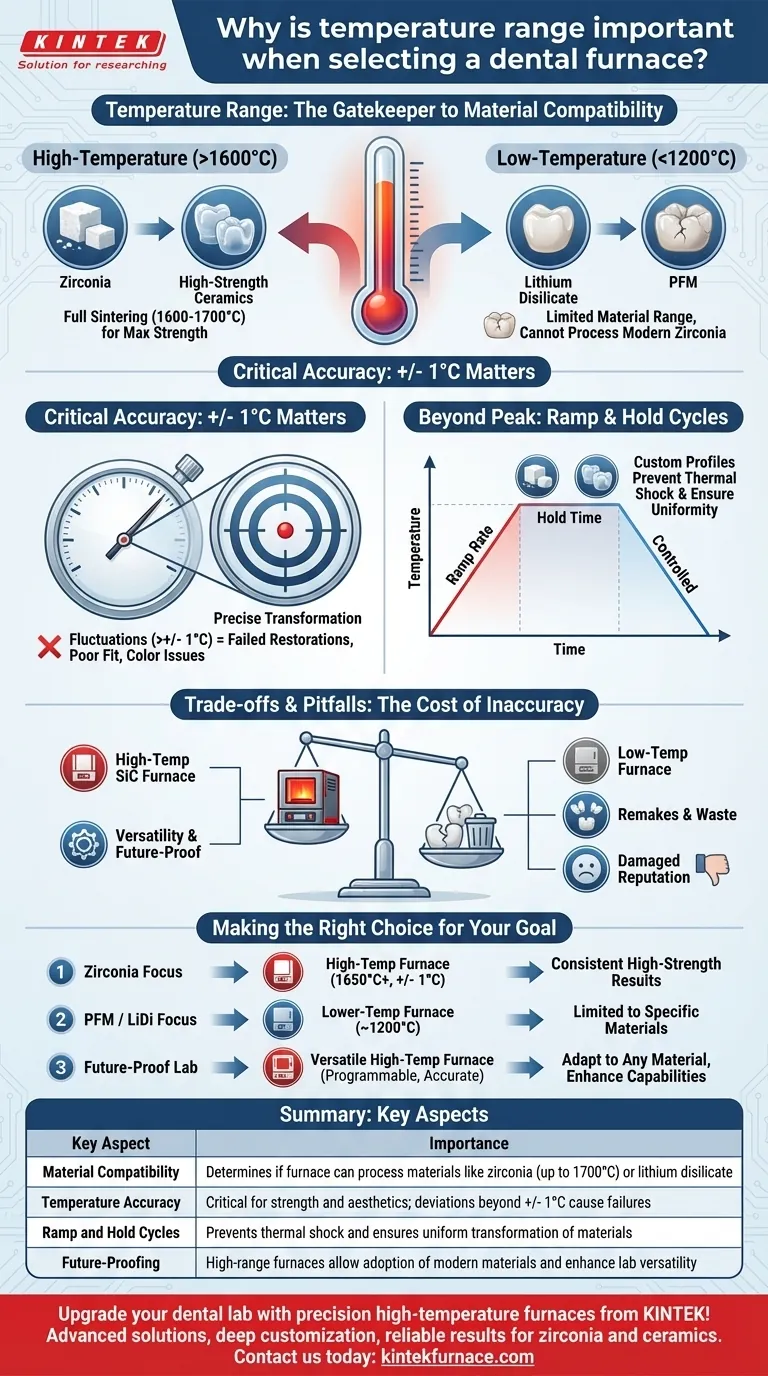

Ultimately, the temperature range dictates what you can create. The single most important function of a dental furnace is to correctly process specific dental materials, and each material—from traditional porcelains to high-strength zirconia—has a non-negotiable temperature recipe. If your furnace cannot reach and precisely maintain these required temperatures, you cannot properly work with that material, fundamentally limiting the services your lab can offer.

Selecting a dental furnace is a long-term investment in your lab's capabilities. The temperature range is not just a technical specification; it is the gatekeeper to material compatibility. Choosing a furnace with an insufficient or inaccurate range directly translates to failed restorations, wasted materials, and an inability to adopt modern dental materials.

Why Temperature Range Defines Your Lab's Capabilities

The connection between temperature and successful restorations is absolute. The physical and aesthetic properties of a final prosthetic are born from a precise, thermally-driven transformation process.

Matching the Furnace to the Material

Different materials undergo their transformation at vastly different temperatures. This process, known as sintering for ceramics like zirconia, is what turns a chalky, pre-sintered block into a dense, high-strength restoration.

Zirconia, for example, requires extremely high temperatures, typically between 1600°C and 1700°C, to achieve full, predictable sintering. A furnace that tops out at 1200°C is physically incapable of processing it.

Conversely, materials like lithium disilicate or certain feldspathic porcelains fire at lower temperatures. The key is that the furnace must be able to execute the specific profile required by the material manufacturer.

The Critical Role of Temperature Accuracy

Simply reaching a peak temperature is not enough. The furnace must maintain that temperature with extreme precision, often within +/- 1°C.

Fluctuations beyond this tolerance, even for a short time, can compromise the final restoration. This can lead to a lack of strength, poor marginal fit, or incorrect translucency and color, forcing a costly remake.

Beyond Peak Temperature: Ramp and Hold Cycles

A material’s firing instructions include more than just a maximum temperature. The furnace program also controls the ramp rate (how quickly the temperature rises) and hold times (how long it stays at specific temperatures).

These programmed cycles are essential for preventing thermal shock and ensuring the material transforms uniformly. A capable furnace allows for full customization of these profiles to perfectly match any material's requirements.

Understanding the Trade-offs and Pitfalls

Choosing a furnace involves balancing cost, capability, and future needs. Overlooking the nuances of temperature performance is a common and expensive mistake.

High-Temperature vs. Low-Temperature Furnaces

Furnaces designed for high-temperature sintering (often called "sintering furnaces") use robust heating elements, like silicon carbide (SiC), to reliably reach and sustain temperatures above 1600°C. They are more versatile but typically represent a higher initial investment.

Lower-temperature "porcelain furnaces" are suitable for materials like PFM and some ceramics, but they will prevent you from working with most modern high-strength zirconia.

The Hidden Cost of Inaccuracy

Investing in a furnace with poor temperature control is a classic example of a false economy. The initial savings are quickly erased by the direct and indirect costs of remakes.

These costs include wasted materials, lost technician time, shipping fees, and, most importantly, damage to your lab's reputation for quality and reliability.

Chamber Size and Temperature Uniformity

A larger chamber is only useful if the temperature is consistent throughout. Poorly designed furnaces can have "cold spots" where the temperature is lower than the target.

This leads to inconsistent sintering within a single batch, where some units may be perfectly processed while others are under-sintered and weak. Always verify the manufacturer's claims of temperature uniformity.

Making the Right Choice for Your Goal

Your decision should be guided by the materials you use today and the ones you plan to adopt tomorrow.

- If your primary focus is high-strength zirconia restorations: You must select a sintering furnace guaranteed to reach at least 1650°C with exceptional accuracy (+/- 1°C).

- If your primary focus is PFM or lithium disilicate: A furnace with a maximum range around 1200°C can meet your needs, but be aware this limits your ability to work with many popular zirconia brands.

- If you are building a versatile, future-proof lab: Prioritize a high-temperature sintering furnace with fully programmable cycles and proven temperature accuracy to accommodate the widest possible range of current and future materials.

Ultimately, choosing the right furnace is about empowering your lab to produce consistent, high-quality results for years to come.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Material Compatibility | Determines if furnace can process materials like zirconia (up to 1700°C) or lithium disilicate |

| Temperature Accuracy | Critical for strength and aesthetics; deviations beyond +/- 1°C cause failures |

| Ramp and Hold Cycles | Prevents thermal shock and ensures uniform transformation of materials |

| Future-Proofing | High-range furnaces allow adoption of modern materials and enhance lab versatility |

Upgrade your dental lab with precision high-temperature furnaces from KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your furnace perfectly matches unique experimental needs, empowering you to work with materials like zirconia and ceramics reliably. Contact us today to discuss how we can enhance your lab's efficiency and expand your service offerings!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time