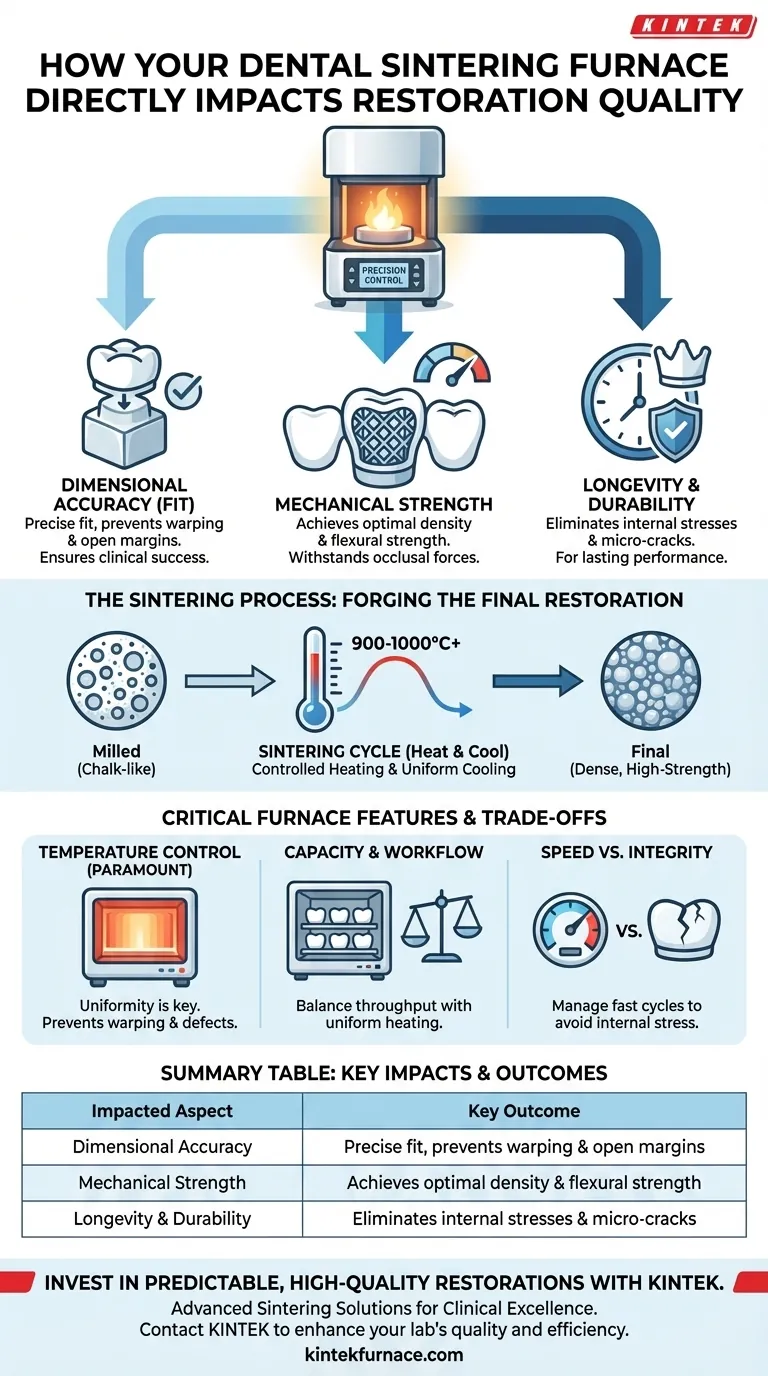

The choice of a dental sintering furnace is a critical decision, as it directly determines the final quality of a dental restoration. The furnace has a direct impact on the restoration's dimensional accuracy (fit), its mechanical strength, and its overall longevity and durability. An appropriate furnace executes the sintering process with precision, preventing defects like warping or cracking that compromise clinical success.

A sintering furnace is not just a heating element; it is a precision instrument. Its ability to deliver uniform and accurate temperature control throughout the entire cycle is the single most important factor determining whether a restoration will be clinically successful or a costly failure.

How Sintering Forges the Final Restoration

To understand the furnace's impact, we must first understand the sintering process itself. This is where a milled, chalk-like restoration is transformed into a dense, high-strength final product.

The Fundamental Goal: Fusing Particles

Sintering is a process that heats ceramic materials, like zirconia, to a temperature just below their melting point. This causes the individual particles to fuse together, eliminating the porous space between them and creating a solid, dense object.

The Critical Role of Temperature

This transformation requires a precise thermal cycle. The furnace must gradually raise the temperature, often to 900-1000°C or higher, and hold it for a specific duration. This precise control ensures the material achieves its target density and strength.

The Importance of a Controlled Cycle

Just as important as the heating phase is the cooling phase. The furnace must cool down slowly and in a controlled manner. Rapid cooling can induce thermal shock, creating internal stresses and micro-cracks that can lead to a catastrophic fracture of the restoration later on.

The Direct Impact on Clinical Quality

Any deviation in the sintering process translates directly to a tangible, clinical outcome. A high-quality furnace provides the consistency needed to avoid these problems.

Ensuring Dimensional Accuracy and Fit

The most immediate impact of a poor furnace is an inaccurate restoration. If the temperature within the heating chamber is not perfectly uniform, the zirconia will shrink unevenly, causing warping. This results in a poor marginal fit, leading to open margins, cement washout, and eventual clinical failure.

Achieving Optimal Mechanical Strength

A furnace that fails to reach or maintain the correct temperature will produce an under-sintered restoration. This material will not achieve its optimal density, resulting in significantly lower flexural strength. The crown or bridge will be brittle and incapable of withstanding normal occlusal forces.

Guaranteeing Longevity and Durability

The combination of a perfect fit and maximum strength creates a durable, long-lasting restoration. A furnace that provides uniform heating and controlled cooling ensures the final product is free from the internal stresses and defects that can compromise its structural integrity over time.

Understanding the Trade-offs

While all furnaces perform the same basic function, their design and technology create important differences in outcomes and workflow.

Temperature Control is Paramount

The most critical feature is the accuracy and uniformity of temperature control. High-quality furnaces use superior heating elements and advanced controllers to ensure every part of the restoration, regardless of its position in the chamber, experiences the exact same thermal cycle. This is the foundation of predictable results.

Capacity and Workflow Efficiency

Furnace capacity is a primary consideration for production. A larger furnace allows a lab to sinter more restorations in a single cycle, directly increasing throughput and efficiency. This must be balanced against the need for uniform heating, which can be more challenging in a larger chamber.

Speed vs. Structural Integrity

Many modern furnaces offer "speed" or "fast" sintering cycles. While these can dramatically improve turnaround times, they place extreme demands on the furnace's ability to heat and cool rapidly without compromising the material. This is a trade-off that must be carefully managed, as improper fast-cycling can easily introduce the internal stresses that lead to failure.

Making the Right Choice for Your Goal

Selecting a furnace requires aligning its capabilities with your lab's primary objectives.

- If your primary focus is clinical excellence and consistency: Prioritize furnaces renowned for their precise temperature control and uniform heat distribution above all other features.

- If your primary focus is high-volume production: Consider furnace capacity and validated fast-sintering cycles that are proven not to compromise the material's structural integrity.

- If your primary focus is material versatility: Ensure the furnace has fully programmable cycles capable of handling the unique temperature profiles of a wide range of modern ceramics and zirconias.

Ultimately, investing in a high-quality sintering furnace is a direct investment in the predictability and quality of every restoration you produce.

Summary Table:

| Impacted Aspect | Key Outcome |

|---|---|

| Dimensional Accuracy | Precise fit, prevents warping and open margins |

| Mechanical Strength | Achieves optimal density and flexural strength |

| Longevity & Durability | Eliminates internal stresses and micro-cracks for lasting performance |

Invest in Predictable, High-Quality Dental Restorations with KINTEK

Your sintering furnace is the cornerstone of clinical success. Leveraging exceptional R&D and in-house manufacturing, KINTEK provides dental laboratories with advanced sintering furnace solutions. Our product line, including high-precision Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique workflow and material requirements.

Ensure every crown and bridge achieves perfect fit, maximum strength, and long-term durability. Contact KINTEK today to discuss how our sintering solutions can enhance your lab's quality and efficiency.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision