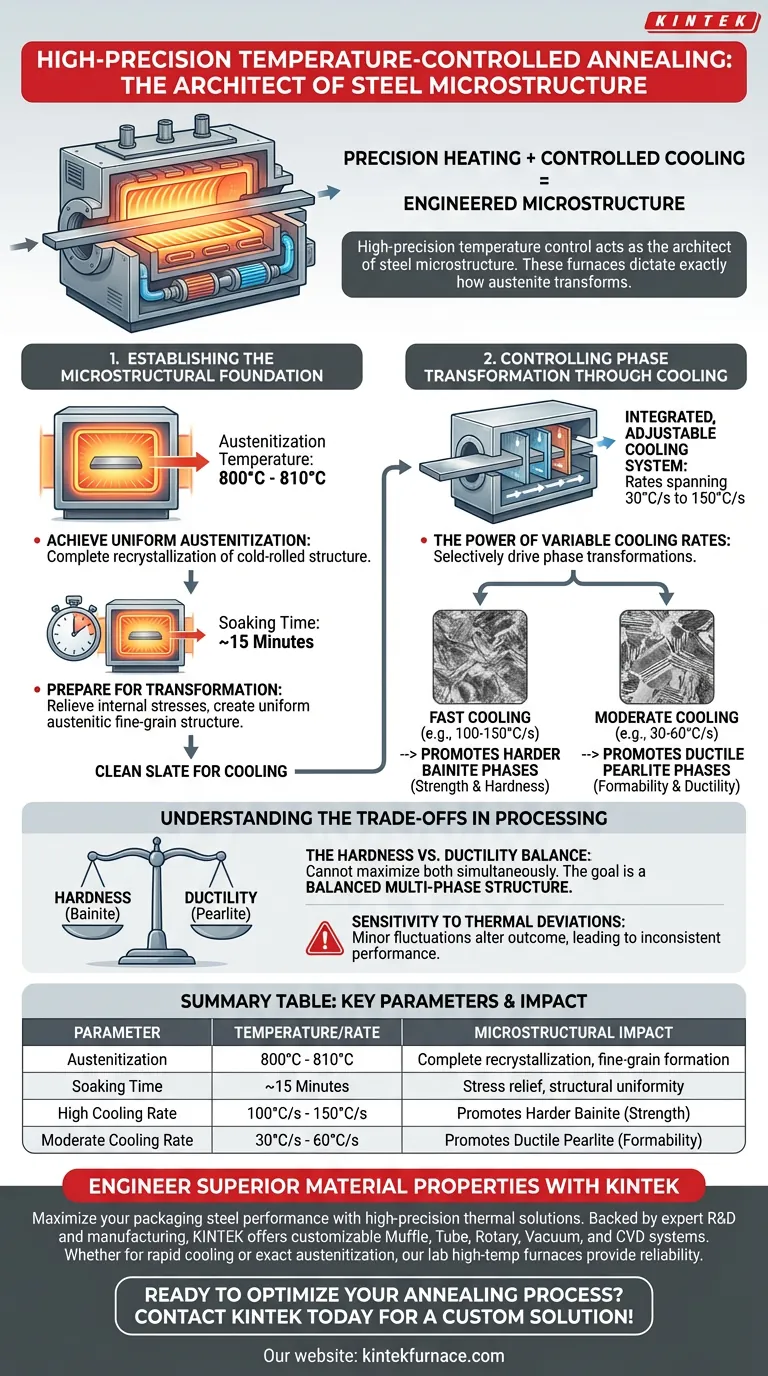

High-precision temperature control acts as the architect of steel microstructure. By heating steel to specific austenitization temperatures (around 810°C) and utilizing strictly regulated cooling rates between 30°C/s and 150°C/s, these furnaces dictate exactly how austenite transforms. This capability enables the deliberate creation of specific multi-phase microstructures, such as bainite or pearlite, which directly define the final mechanical performance of packaging steel.

The furnace's true value lies not just in heating, but in its ability to execute precise cooling trajectories. By manipulating the cooling rate, manufacturers can selectively drive phase transformations to engineer the exact trade-off between hardness and ductility required for the application.

Establishing the Microstructural Foundation

To control the final properties of packaging steel, you must first reset the material's internal structure.

Achieving Uniform Austenitization

High-precision furnaces heat specimens to a pre-set target, typically between 800°C and 810°C.

Maintaining this temperature with exactitude ensures the complete recrystallization of the cold-rolled microstructure.

Preparing for Transformation

Holding the steel at this temperature for a specific duration (e.g., 15 minutes) creates a uniform austenitic fine-grain structure.

This "soaking" period relieves internal stresses accumulated during prior processing, effectively creating a clean slate for the cooling phase.

Controlling Phase Transformation Through Cooling

The formation of multi-phase microstructures occurs primarily during the cooling process, not the heating process.

The Power of Variable Cooling Rates

The defining feature of these furnaces is an integrated, adjustable cooling system capable of rates spanning 30°C/s to 150°C/s.

This wide dynamic range allows operators to move beyond simple quenching or slow cooling.

Selective Phase Formation

By selecting a specific rate within this range, you control the transformation kinetics of the austenite.

You can steer the microstructure toward bainite (generally harder) or pearlite (generally softer), depending on the cooling velocity applied.

Understanding the Trade-offs in Processing

While high-precision annealing offers control, it requires navigating inherent material compromises.

The Hardness vs. Ductility Balance

You cannot maximize every property simultaneously. Promoting harder phases like bainite often comes at the cost of ductility.

The goal of the furnace is to achieve a balanced multi-phase structure where the steel is hard enough to protect packaged goods but ductile enough to be formed without cracking.

Sensitivity to Thermal Deviations

Because the window for specific phase transformations is narrow, even minor fluctuations in furnace temperature or cooling consistency can alter the outcome.

A lack of precision here results in inconsistent microstructures, leading to variability in toughness and performance in low-temperature applications.

Making the Right Choice for Your Goal

When configuring your annealing process, your target microstructure should be dictated by the end-use of the packaging steel.

- If your primary focus is Strength and Hardness: Prioritize higher cooling rates to promote the formation of bainite phases within the microstructure.

- If your primary focus is Formability and Ductility: Utilize moderate cooling rates to favor pearlite formation and ensure the retention of fine-grain structures.

Precision annealing transforms steel processing from a brute-force thermal task into a delicate, tunable science of microstructural engineering.

Summary Table:

| Parameter | Temperature/Rate | Microstructural Impact |

|---|---|---|

| Austenitization | 800°C - 810°C | Complete recrystallization and fine-grain formation |

| Soaking Time | ~15 Minutes | Relief of internal stresses and structural uniformity |

| High Cooling Rate | 100°C/s - 150°C/s | Promotes Harder Bainite phases for strength |

| Moderate Cooling Rate | 30°C/s - 60°C/s | Promotes Ductile Pearlite phases for formability |

Engineer Superior Material Properties with KINTEK

Maximize your packaging steel performance with high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific microstructural engineering needs. Whether you require rapid cooling trajectories or exact austenitization control, our lab high-temp furnaces provide the reliability your research demands.

Ready to optimize your annealing process? Contact KINTEK today for a custom solution!

Visual Guide

References

- R. Uzun, Yasemin Kılıç. Effect of Chemical Composition and Annealing Parameters for Advanced Packaging Steel Applications. DOI: 10.16984/saufenbilder.1599129

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a high-pressure reactor with a PTFE lining required for V-NbOPO4@rGO? Ensure Purity in Acidic Synthesis

- Why is an electric heating furnace integrated with a capsule-piercing reactor? Ensure Precise Fluid Analysis

- What is the necessity of a laboratory vacuum drying oven for photocatalytic powders? Protect Your Material Integrity

- How do quartz-capped vials facilitate the pyrolysis of magnetic chitosan carbon? Master Localized Reducing Atmospheres

- What is the primary function of a laboratory drying oven in cotton stalk pyrolysis? Ensure Data Integrity

- How does Thermogravimetric Analysis (TGA/DTG) provide industrial guidance? Optimize Blast Furnace Dust Treatment

- What is the purpose of secondary heating at 200 degrees Celsius for Ge-S-Cd alloys? Ensure Stress-Free Samples

- What is the role of a rotary evaporator in the extraction of isopulegyl acetate? Protect Purity and Stability