The purpose of secondary heating at 200 degrees Celsius is to perform a critical thermal annealing process on the Ge-S-Cd alloy. This procedure, followed by natural cooling inside the furnace, is designed to eliminate internal thermal stresses that accumulate during the pressing and melting phases of fabrication.

This annealing step effectively stabilizes the alloy's microstructure. By removing residual stress, the process ensures mechanical durability and significantly improves the reliability of subsequent electrical performance tests, particularly resistivity measurements.

The Mechanics of Stress Relief

Addressing Fabrication Stress

During the initial creation of Ge-S-Cd samples, the materials undergo pressing and melting. These high-energy processes force the material into shape but often trap significant thermal energy within the lattice.

Without intervention, this trapped energy manifests as internal thermal stress. This stress creates a volatile microstructure that is prone to physical failure or inconsistent behavior.

The Role of Controlled Cooling

The secondary heating phase is only half of the solution; the cooling method is equally vital. The protocol dictates natural cooling inside the furnace chamber.

This utilizes the furnace's insulation to slow down the temperature drop. By avoiding rapid cooling, the material settles gradually, preventing the re-introduction of stress that would occur with thermal shock.

Why Stabilization Matters

Improving Mechanical Stability

The primary physical outcome of this annealing process is mechanical stability. By relaxing the internal tensions, the structural integrity of the alloy is preserved.

This reduces the likelihood of the sample cracking or warping over time. It transforms a fragile, stressed sample into a robust material ready for testing.

Enhancing Electrical Accuracy

Internal stress does not just affect physical strength; it distorts electrical properties. Stressed atomic lattices can scatter electrons unpredictably, leading to noisy or erroneous data.

By stabilizing the microstructure, you ensure that tests like resistivity measurements reflect the true properties of the alloy, not artifacts of the manufacturing process.

Understanding the Trade-offs

Time vs. Data Quality

The most obvious trade-off is processing time. Adding a two-hour heating cycle plus a long, natural cooling period significantly extends the fabrication timeline.

However, skipping this step to save time introduces a high risk of data variance. The time saved is often negated by the need to re-test samples that yield inconsistent results due to internal stress.

Temperature Specificity

The protocol specifies 200 degrees Celsius. This is a precise operating window.

DEviating from this temperature carries risks. A lower temperature may fail to mobilize the lattice enough to relieve stress, while a significantly higher temperature could inadvertently alter the phase composition of the Ge-S-Cd alloy itself.

Making the Right Choice for Your Goal

To ensure your Ge-S-Cd samples are fit for purpose, consider the following regarding this annealing step:

- If your primary focus is mechanical durability: Prioritize the furnace cooling phase to ensure the physical structure remains intact and free of fractures.

- If your primary focus is electrical precision: Strictly adhere to the 200°C dwell time to eliminate noise in your resistivity data.

Ultimately, this thermal treatment is the essential bridge between a raw, unstable sample and a reliable scientific baseline.

Summary Table:

| Parameter | Process Step | Benefit for Ge-S-Cd Alloy |

|---|---|---|

| Temperature | 200°C Secondary Heating | Relieves internal thermal stresses from fabrication |

| Cooling Method | Natural Furnace Cooling | Prevents thermal shock and lattice distortion |

| Microstructure | Thermal Annealing | Stabilizes the atomic lattice for mechanical durability |

| Data Integrity | Stress Elimination | Ensures accurate and reliable resistivity measurements |

Elevate Your Material Research with KINTEK

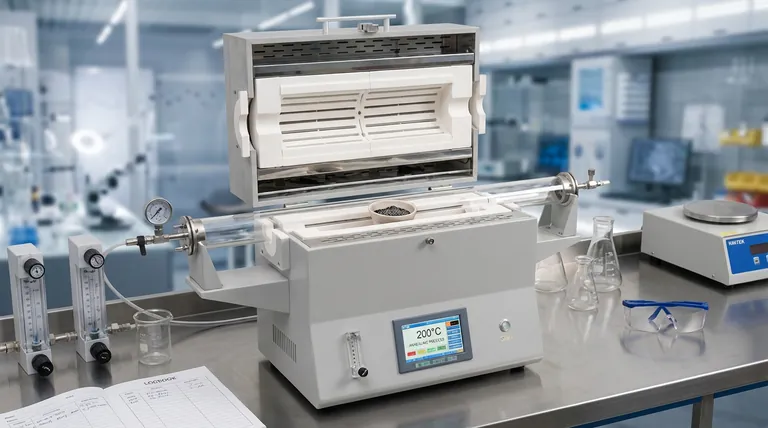

Precise thermal treatment is the difference between data variance and scientific breakthrough. At KINTEK, we provide the high-performance laboratory solutions required to master complex protocols like Ge-S-Cd alloy annealing.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard high-temperature furnaces or systems fully customizable for your unique research needs, our technology ensures the uniform heating and controlled cooling rates essential for microstructure stabilization.

Ready to ensure the mechanical durability and electrical precision of your samples?

Contact our specialists today to find your ideal thermal solution.

References

- Zainab Abd Al-hadi, Kareem A. Jasim. The Effect of Partial Substitution of Ge-S-Cd Alloys on the Density of Energy States. DOI: 10.30526/37.1.3314

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What mechanism causes the formation of micro-cracks in zinc clinker during microwave heating? Boost Leaching Efficiency

- What is the purpose of performing homogenization at 1250°C? Optimizing Sintered Cobalt-Based Superalloys

- Why is a stainless steel autoclave with a Teflon liner necessary for BiVO4? Ensure Purity & High Performance

- Why is a high-pressure stainless steel autoclave required for activated carbon? Unlock High-Performance Carbon Synthesis

- Why is the adsorption of dioxins more effective using carbon nanotubes (CNTs)? 3x Superior Efficiency Explained

- What advantages does a vacuum drying oven offer? Superior Chemical Stability & Efficient Dehydration

- What are the requirements for sulfur powder loading in MoS2 synthesis? Master the 50-150 mg Precision Range

- Why is cordierite selected as the honeycomb support for HAN decomposition catalysts? Essential Design Insights