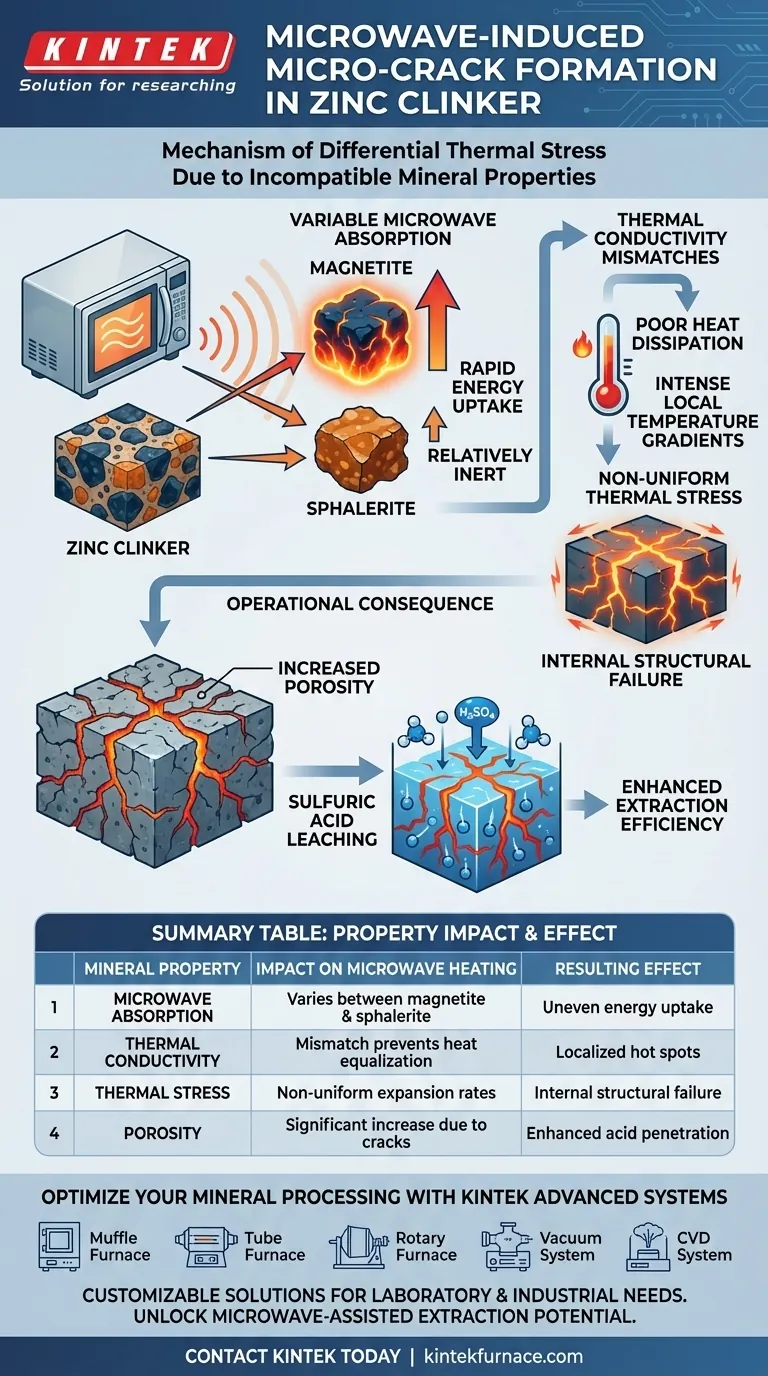

The formation of micro-cracks in zinc clinker is the direct result of incompatible physical properties among its constituent minerals when exposed to microwave energy. Because components like magnetite and sphalerite respond differently to electromagnetic fields, they heat up at uneven rates, causing internal structural failure.

The core mechanism is differential thermal stress. Variations in microwave absorption capacities and thermal conductivities between minerals create intense local temperature gradients, generating non-uniform stresses that fracture the clinker.

The Physics of Differential Heating

Variable Microwave Absorption

Zinc clinker is a heterogeneous material composed of various minerals, notably magnetite and sphalerite.

These components do not behave uniformly; they possess significantly different microwave absorption capacities.

When the microwave field is applied, one mineral may absorb energy rapidly while another remains relatively inert, creating immediate disparities in energy uptake.

Thermal Conductivity Mismatches

In addition to absorbing energy differently, these minerals also differ in their thermal conductivity.

This property dictates how fast heat travels through the material.

The mismatch means that even as heat is generated, it cannot dissipate or equalize uniformly across the clinker, compounding the isolation of high-temperature zones.

From Thermal Gradient to Fracture

Intense Local Temperature Gradients

The combination of uneven absorption and varying conductivity leads to intense local temperature gradients.

Specific spots within the clinker structure become significantly hotter than their immediate surroundings.

Non-Uniform Thermal Stress

These sharp temperature differences result in non-uniform thermal stresses.

As different parts of the material attempt to expand at different rates, the internal tension exceeds the material's structural strength.

This physical stress creates a network of numerous micro-cracks throughout the clinker.

Understanding the Operational Consequence

Increased Porosity

The primary physical outcome of this cracking mechanism is a significant increase in the porosity of the zinc clinker.

The material transforms from a dense solid into a structure permeated with microscopic fissures.

The Role in Leaching

While "cracking" sounds destructive, in this context, it is functionally beneficial.

These cracks act as channels that allow sulfuric acid leaching solutions to penetrate deep into the material.

This facilitates more efficient chemical extraction by exposing a greater surface area to the leaching agent.

Making the Right Choice for Your Goal

To leverage this mechanism effectively, consider your specific objective regarding zinc processing:

- If your primary focus is Extraction Efficiency: Recognize that micro-cracking is a desirable outcome that directly enhances the penetration depth of sulfuric acid solutions.

- If your primary focus is Process Control: Monitor the mineral composition (specifically magnetite and sphalerite levels), as their interaction with the microwave field is the engine driving this thermal stress.

Understanding the link between mineral properties and thermal stress is the key to optimizing microwave-assisted zinc leaching.

Summary Table:

| Mineral Property | Impact on Microwave Heating | Resulting Effect |

|---|---|---|

| Microwave Absorption | Varies between magnetite & sphalerite | Uneven energy uptake |

| Thermal Conductivity | Mismatch prevents heat equalization | Localized hot spots |

| Thermal Stress | Non-uniform expansion rates | Internal structural failure |

| Porosity | Significant increase due to cracks | Enhanced acid penetration |

Optimize Your Mineral Processing with KINTEK Advanced Systems

Unlock the full potential of microwave-assisted extraction with precision-engineered equipment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs.

Whether you are targeting improved leaching porosity or need precise control over thermal gradients, our team is ready to help you design the perfect solution. Contact KINTEK today to enhance your lab's efficiency!

Visual Guide

References

- Bagdaulet Kenzhaliyev, Symbat Tugambay. Microwave Pre-Treatment for Efficient Zinc Recovery via Acid Leaching. DOI: 10.3390/ma18112496

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does thermal annealing play in the post-treatment of CZTSSe nanocrystals? Optimize Phase Purity & Crystallinity

- What is the technical value of a Hydrogen Reduction-type Test Furnace in green steelmaking? Scale Sustainable Production

- Why are different cooling methods compared for GFRP post-fire performance? Evaluate Thermal Shock & Safety Risks

- What are the primary functions of high-purity nitrogen flow in carbon pyrolysis? Optimize Purity and Pore Structure

- What are the primary applications of a high-precision electric furnace in biomass characterization? Unlock Key Insights

- Why is a specialized roasting simulation device necessary? Optimize Iron Ore Pellet Quality and Strength

- What is the purpose of vacuum sputtering systems for haptic device electrodes? Achieve High-Precision Metal Deposition

- Why is it necessary to preheat the mold for Mg-8Li-3Al-0.3Si alloy? Unlock Peak Casting Integrity