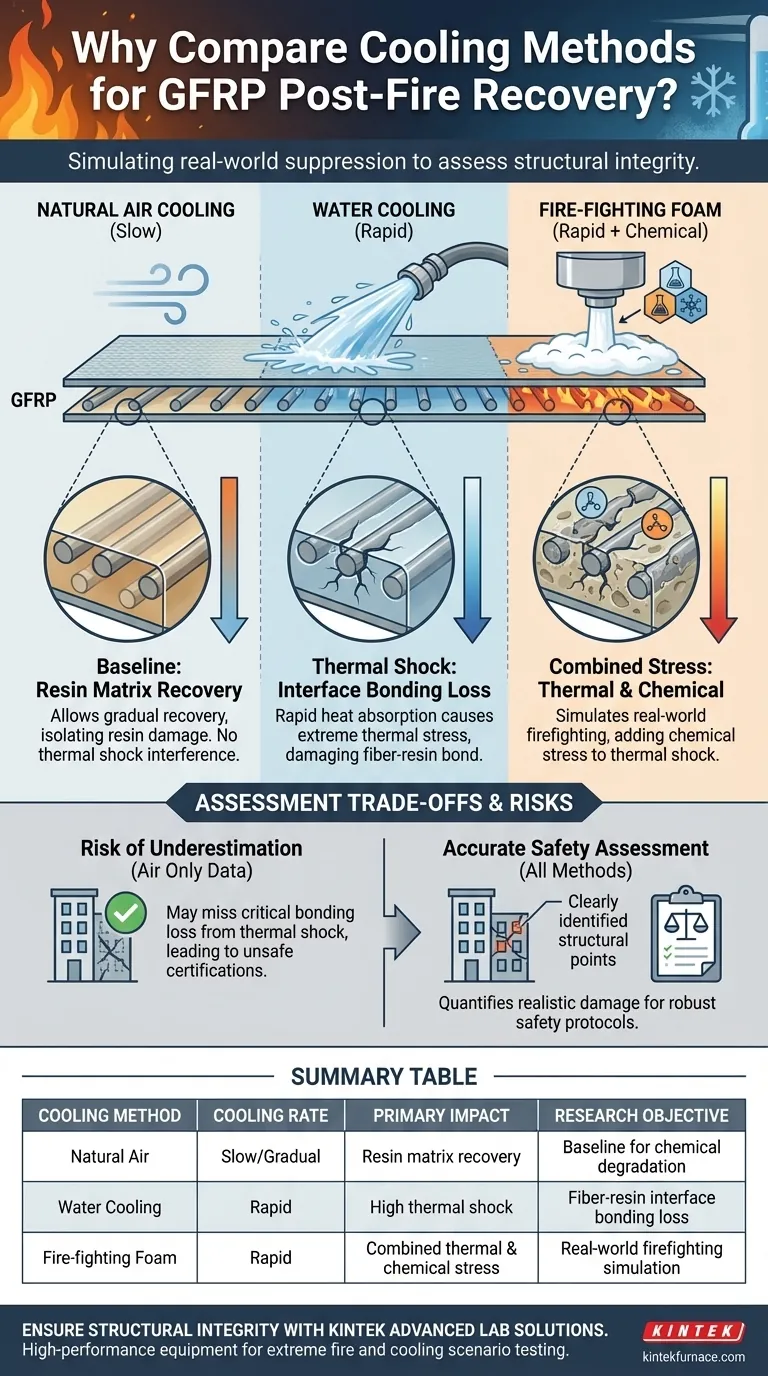

Comparing distinct cooling methods is essential because it simulates the wide range of real-world fire suppression scenarios that structural materials face. By evaluating Glass Fiber Reinforced Polymer (GFRP) against natural air, water, and fire-fighting foam, researchers can distinguish between damage caused by gradual cooling versus the extreme thermal shock associated with active firefighting. This comparison allows for a precise analysis of how different cooling rates impact the resin matrix and the critical fiber-resin interface bonding.

While fire causes the initial structural damage, the method used to extinguish it creates secondary effects that are equally critical. Understanding the difference between slow cooling and rapid thermal shock is vital for accurately assessing the residual safety of GFRP structures.

Simulating Real-World Fire Suppression

Replicating Secondary Effects

A fire event involves more than just heat; it involves the intervention used to stop it.

Comparing cooling media allows researchers to simulate the secondary effects of fire suppression. This ensures that safety assessments account for the actual conditions a building faces during an emergency, rather than just a theoretical heating curve.

Beyond the Flames

Standard heat tests often assume a natural cool-down period. However, real fires are typically suppressed aggressively.

To create valid safety guidelines, researchers must understand how the sudden introduction of suppression agents like water or foam alters the material's recovery compared to a building that burns out and cools naturally.

Analyzing the Impact of Cooling Rates

Natural Air Cooling: The Baseline

Natural air cooling serves as the control for "slow cooling."

This method allows researchers to isolate and study the damage to the resin matrix. By allowing the material to return to ambient temperature gradually, scientists can observe the gradual recovery of resin matrix damage without the interference of sudden physical stress.

Water and Foam: Rapid Heat Absorption

Water and fire-fighting foam function through rapid heat absorption.

These methods induce "rapid cooling," causing the temperature of the GFRP to plummet almost instantly. This provides data on how the material behaves when subjected to maximum thermal gradients.

Thermal Stress on the Interface

The rapid cooling from water and foam generates extreme thermal stress.

This stress specifically targets the fiber-resin interface bonding strength. Analyzing this damage is crucial because a loss of bonding strength can compromise the structural integrity of the GFRP, even if the exterior looks relatively undamaged.

Understanding the Trade-offs in Assessment

The Risk of Underestimation

Relying solely on natural air cooling data can lead to dangerous underestimations of damage.

A structure that cools slowly may retain certain mechanical properties that are destroyed during the thermal shock of water suppression. Excluding rapid cooling tests could result in safety certifications for buildings that are actually structurally compromised.

Distinguishing Stress Types

It is difficult to separate chemical damage from physical damage without comparison.

By comparing chemically active agents (foam) against physical agents (water) and passive agents (air), researchers can better identify whether failure is driven by chemical degradation or purely by the physics of thermal contraction.

Making the Right Choice for Your Goal

When designing safety protocols or evaluating material performance, the cooling method you analyze determines the relevance of your data.

- If your primary focus is studying resin characteristics: Focus on natural air cooling to observe the gradual recovery of the matrix without the noise of thermal shock.

- If your primary focus is structural safety assessments: Prioritize water and foam cooling data to quantify the loss of fiber-resin bonding strength caused by realistic suppression efforts.

By simulating the full spectrum of cooling scenarios, engineers can generate safety assessments that withstand the harsh reality of emergency interventions.

Summary Table:

| Cooling Method | Cooling Rate | Primary Impact | Research Objective |

|---|---|---|---|

| Natural Air | Slow/Gradual | Resin matrix recovery | Baseline for chemical degradation |

| Water Cooling | Rapid | High thermal shock | Fiber-resin interface bonding loss |

| Fire-fighting Foam | Rapid | Combined thermal & chemical stress | Real-world firefighting simulation |

Ensure Structural Integrity with KINTEK Advanced Lab Solutions

When failure isn't an option, your material testing must be precise. KINTEK provides the high-performance heating and testing equipment needed to simulate extreme fire scenarios and cooling gradients. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temp furnaces—all fully customizable to your unique structural research needs.

Ready to elevate your material safety assessments? Contact KINTEK experts today for specialized solutions tailored to your GFRP research.

Visual Guide

References

- Junjie Wu, Chuntao Zhang. Modified Constitutive Models and Mechanical Properties of GFRP after High-Temperature Cooling. DOI: 10.3390/buildings14020439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- How can I improve my vacuum pump performance? Optimize Your System for Deeper Vacuum & Faster Pump-Down

- What role does a high-temperature furnace play in the chemical activation of carbon materials? Master KOH Activation

- Why is graphite furnace AAS more sensitive than flame AAS? Unlocking Trace-Level Detection

- What is the design logic behind the double-layer reactor structure used in the ITSP process? Optimize Your Fuel Quality

- What is the purpose of vacuum sputtering systems for haptic device electrodes? Achieve High-Precision Metal Deposition

- What is the purpose of employing Ozone (O3) treatment following the AS-ALD of Al2O3? Boost Film Purity and Density

- How does a forced-air drying oven contribute to asphalt degradation? Accelerate Material Salt Erosion Simulation

- Why is the high-precision control of argon (Ar) and nitrogen (N2) flow ratios critical in CrSiN-Y coating fabrication?